D&B Construction’s partnership with Quality Buildings, a commercial framing contractor, began this year through their work on Kennett Pointe, a ground-up mixed-use property currently under construction in Kennett Square, PA.

Elmer Zook, Founder and President of Quality Buildings, has been part of the industry for 18 years now. “We like expanding our client base as well as building new relationships in the construction industry. D&B came on our radar a few years ago as a fast-growing player amongst other GC’s,” he reflects.

The fruition of Quality Buildings’ relationship with D&B began as a culmination of a handful of work connections, including having known our CEO, Dan Gring, through their involvement at Lancaster Berks Next Gen Construction Connect. At Kennett Pointe they supplied a complete furnish and installed a framing package that included manufacturing of pre-fabricating wall panels, floor and roof trusses and installation of the windows and doors.

“Quality Building produces quality work, and they are easy to communicate with. It is always a pleasure working with them, and I would work with them again in a heartbeat,” says John Ruza, Senior Superintendent overseeing the jobsite in Kennett Square.

About Quality Buildings:

This turnkey framing contractor was founded in 2008 as a home improvement contractor and Agricultural/Equestrian facilities design and build contractor. They’ve built many custom designed horse barns and riding arenas in NY, NJ, DE, MD, and VA.

Having experience in design and build as a contractor, coupled with a desire to work closer to home versus constant traveling, commercial framing seemed to fit well with their philosophy of working together as a team with other trades to deliver a well-planned project. In 2014, their sole focus became commercial framing for multi-family apartments, senior living and hotels. Completing between 12-15 projects annually, the company has an annual gross revenue of $20,000,000+ in the multi-family, senior living and hospitality sectors. Quality Buildings started pre-fabricating wall panels out of their own facility and continued to expand.

Today, Quality Buildings specializes in offsite pre-fabricated building components, as well as framing components, wall panels, floor trusses, roof trusses and all needed equipment and labor for a complete framing system. Offering VE options and full 3D modeling capabilities for clash detection, as well as BIM modeling with other trades, they are acknowledged as a leading innovator in wood framing. They also offer structural engineering and Mass Timber construction. Their commitment to provide customers with the finest craftmanship continues to be their anchor 14 years later. Quality Buildings has an employee count of 42, consisting of VDC designers, project managers, pre-fabricated wall panel manufacturing and field carpenters. They also have a steady base of subcontractors they know they can turn to for their larger projects.

“We pride ourselves for having more attention to detail and a higher level of service than our competition,” explains Elmer. “We are the experts in wood framing and strive to present ourselves as such. Every department within Quality Buildings has an in-depth knowledge of wood framing. Our designers are the linchpin of our projects being successful and have an extensive hands-on experience with building these projects in the field.”

Q&A With Elmer Zook, Founder and President of Quality Buildings

Q: What’s the best piece of advice you would give to others looking to get into the industry?

A: “Learn as much as you can about the trade you are a part of and about the trades around you that need your collaboration to do a good job and offer a stellar service. Care about your craft and treat people with respect.”

Q: What do you love most about working in the industry and why?

A: “I love working in the industry and providing a service that goes above and beyond just showing up and swinging a hammer. I love that our team is intentional about getting into the nuts and bolts of a project and finding new and better ways to get the job done.”

Q: Anything else you’d like to add?

A: “We appreciate D&B entrusting QB with being your Framing partner on this project and look forward to many more in the future.”

Wyomissing, PA – On Monday, May 9, Stratix Systems and D&B Construction held a topping off ceremony to commemorate the completion of the fifth floor of Stratix Systems’ new corporate headquarters at 200 North Park Road, Wyomissing. This 80,000 SF building, which is currently receiving extensive exterior and interior renovations, was part of the original Wyomissing Industries. View coverage from the event here!

Learn more about the details and history of this adaptive reuse project here on our blog.

“Topping Off” is a long-standing tradition among construction workers that commemorates the completion of the building’s structure as the final steel beam is placed. In attendance for the topping off ceremony were building owner and future tenant, Stratix Systems, the general contractor, D&B Construction, the project architect, RHJ Associates, the Project Engineer, Martarano Engineering, Inc., the Structural Engineer, Structure Labs, LLC, and the steel trade partner, United Weld Services LLC.

Dan Gring, Chief Executive Officer of D&B Construction, commented on the importance of high-end commercial office renovations such as this one: “Adaptive reuse projects like the Stratix Systems corporate headquarters are important because they revitalize historic buildings, creating a stronger future in the community. We’re thrilled to lead the project team.”

According to Brent Simone, Stratix Systems president, “We think it’s important for us to reinvest in our community. In fact, we’re committed to that philosophy. That’s why we chose the former Wyomissing Industries property. Not only is it a gorgeous building, one with a significant history for Wyomissing and Berks County, it gives us the size and flexibility to accommodate our growth for many years to come.”

About Stratix Systems:

Stratix Systems is one of the region’s leading technology solutions partners. With a history that spans nearly 50 years, more than 130 IT professionals, and offices in Wyomissing, Bethlehem, King of Prussia and York, Pennsylvania, as well as Edison, New Jersey — it’s no wonder why Stratix Systems is the partner of choice for over 6,500 organizations throughout Pennsylvania and New Jersey. Very few providers in the country can match the vast array of technology solutions and responsive service available from Stratix Systems. Whatever a client’s technology needs — Managed IT Services, Cybersecurity, Imaging & Printing Solutions or Document Management, Stratix Systems has the people, the technologies, the expertise and the experience to deliver the advanced solutions and support clients rely on. Stratix Systems has earned recognition as a member of the prestigious Inc. 5000, as well as recognition as one of the fastest growing companies from both Lehigh Valley Business and the Greater Reading Chamber Alliance. The company has also been recognized by Ricoh USA with Ricoh’s Circle of Excellence designation and Ricoh USA’s President’s Award. Stratix Systems has repeatedly earned certification as a Pros Elite 100 dealer – the only Pros Elite 100 dealer in the region – a certification that recognizes the top-shelf achievement and client service of the top 100 service organizations in the country. Learn more at www.stratixsystems.com.

About D&B Construction:

Founded in 2010 by Dan Gring and Brennan Reichenbach, D&B Construction has grown into one of the region’s most trusted construction firms. Headquartered in Reading, Pennsylvania the company is driven by a commitment to quality and transparency. They have grown from the two founding members to over 50 employees with an additional office outside of Philadelphia to conveniently serve the Delaware Valley region. Today they are a full-service construction management firm offering a variety of services to commercial clients in the healthcare, multi-family, professional office, retail / hospitality, institutional, and industrial sectors. Delivering an individualized, superior experience to all of our clients, D&B is a team of genuinely good people who love to build and work hard, with their success built upon long-standing relationships anchored in honesty, trust, and fairness. Leveraging vast design and build experience, D&B is the conduit for business owners, corporations, and developers looking to enhance the places in which they work, grow, and invest. Completing projects safely, within budget, and on time to minimize any disruption to business is always top priority. For more information, visit online at: dbconstructiongrp.com.

Just over a year ago, D&B Construction began demolition of the exterior and interior of an 80,000 SF building in the heart of Wyomissing, PA. The culmination of this design-build core and shell project will reveal a completely renovated building offering five stories of high-end commercial office space. The building will be home to the headquarters of Stratix Systems, a leading technology solutions partner that is rooted in Wyomissing. Three floors totaling 45,000 SF of space will be fit out for Stratix Systems and two floors totaling 30,000 SF will be available for future tenants.

Some highlights of this project include:

-Asbestos abatement and lead paint removal

-The removal of all interior furnishings, finishes, partition walls, and MEP’s to make way for all new floor configurations and finishes specific to Stratix’s wishes and providing clear space for future tenants

-Removal of sprinkler and fire alarm systems to allow for all new NFPA 13 sprinkler systems, including a new fire pump and fire alarm systems

-Removal of existing exterior insulation finish system and aluminum windows made way for an upgraded EIFS and enlarged aluminum windows restored to their original size.

-Removal of the entire roofing system and entrance vestibules / porticos to make way for a completely new roof system, as well as a five-story storefront entrance with stairs and two passenger elevators

-A freight elevator and loading docks are also being added to the building, while the fifth floor receives an expansion

-Given the intricacies of this project and the fact that safety is our standard at D&B, a full site specific safety plan was created and implemented for this project, including bi-weekly JSA/JHA, weekly site meetings, confined space training and regularly scheduled scaffold inspections.

Stepping Back in Time to the Building’s Original Pioneers:

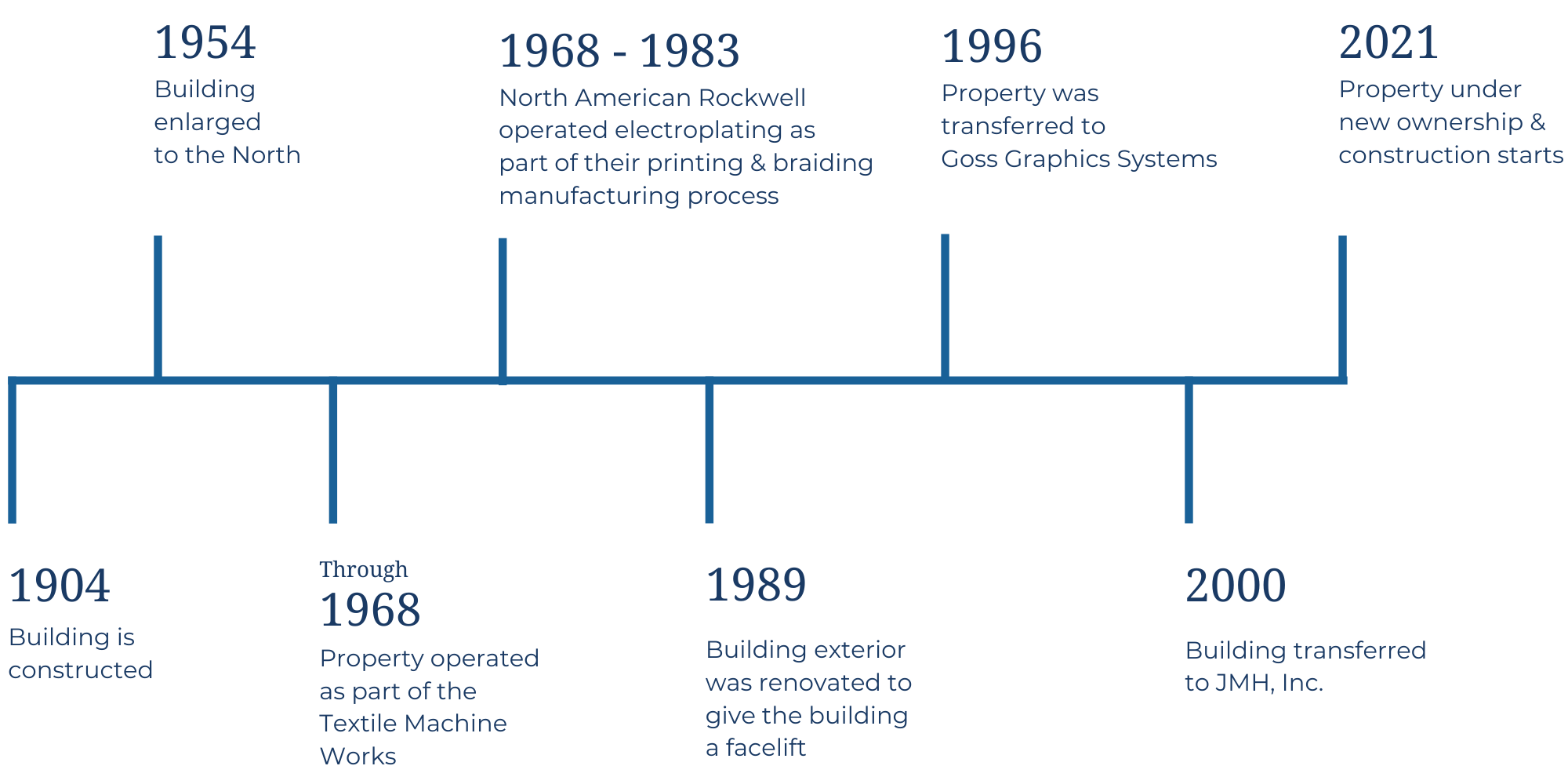

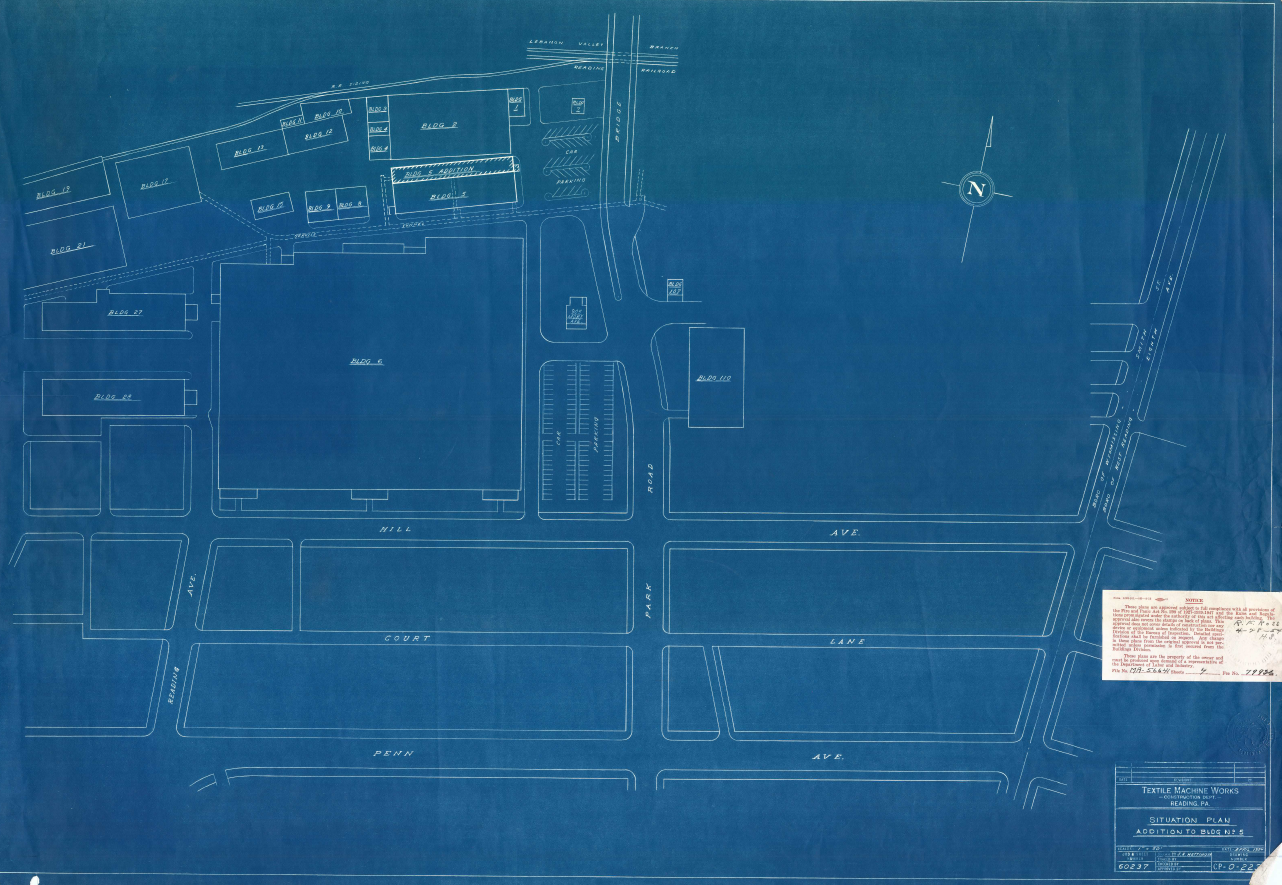

Like many adaptive reuse projects, this building comes with a rich history:

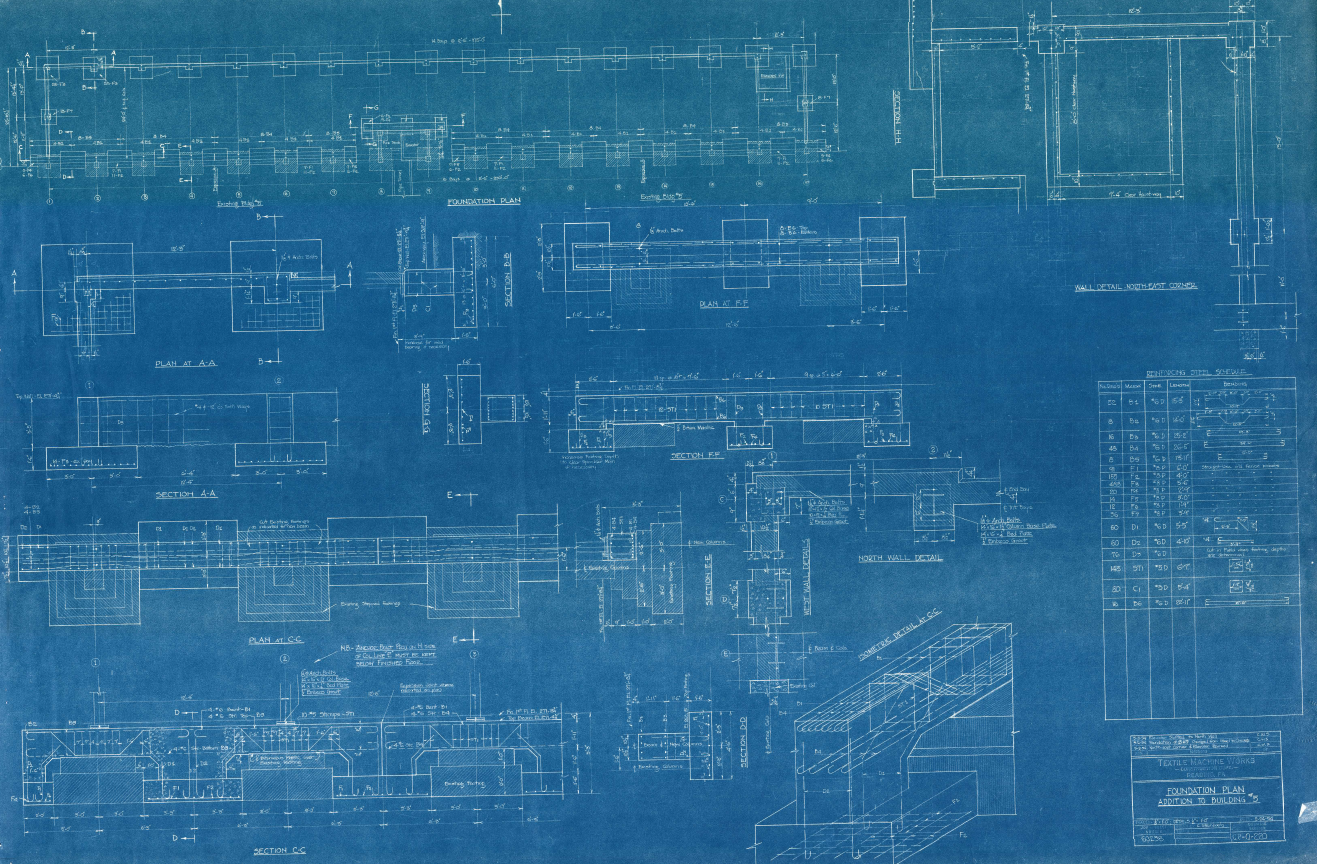

The building was part of the original Wyomissing Industries, a multi-faceted manufacturing enterprise founded by Ferdinand Thun and Henry Janssen in 1906 when they incorporated their three main businesses: the Textile Machine Works (soon to be the future home of Stratix Systems), Narrow Fabric Company (braided products), and the largest full-fashioned knitting mill in the world, the Berkshire Knitting Mills (hosiery and fabrics).

In 1969, following the decline of nylon, the nation’s first outlet center was purchased by VF Corporation. The VF Outlet had six million visiting shoppers annual during its peak, and in 1991 Reading was officially declared “The Outlet Capital of the World.” Today UGI Energy Services’ headquarters, Teleflex, and Tower Health System’s collaboration with Drexel University’s College of Medicine Branch, along with updated restaurant and retail offerings, can be found at the new Knitting Mills that locals and visitors alike have come to know and love.

Adaptive Reuse: A Delicate Balance of Preserving A Building While Paving the Way for the Future

In addition to D&B employees and the project architect, RHJ Associates, approximately 45 of our dedicated Trade Partners, made up of both individuals and entire organizations, have been collectively working to revitalize this space. One such Trade Partner is Pullman Services, who was on site for about four months completing a variety of tasks involving structural repairs to the existing building and installing temporary lintels so more windows could be cut into the building façade. As part of their structural repairs, Pullman restored deteriorated concrete on over 50 columns and girders in the original portion of the building. Their Foreman, Jamie, referred to the project as a unique job. “I’ve never seen columns built like this in my 20 years in the industry,” he explained.

Some of the Trade Partners on this project have multiple contracts from demolition into core and shell. Once all is said and done, approximately 45,000 man hours will have been spent completing this project between over 100 individuals, ranging from Project Manager to laborer.

Some other key players in the building’s transformation include the following Trade Partners:

–EHC Associates completed both interior and exterior demolition, as well as asbestos abatement and lead paint stabilization.

–Paramount Contracting has completed framing and various exterior work, such as the exterior insulation finishing system. (Learn more about our partnership with them here!)

–Shea Roofing is installing the new roof and aluminum clad panels as part of the new exterior finish system

–United Weld Services LLC is erecting steel, which expanded the fifth-floor roof over 26 feet and will be integral in the new entrance lobby

–B&G Glass is installing new windows throughout the building

–Michael C Wall is completing all HVAC work

–H.B. Frazer Company is heading up the electrical work

–Haller Enterprises, Inc. is leading the plumbing work

Anyone that frequently drives over the bridge on Park Road headed towards the Knitting Mills has undoubtedly received a first row look at the transformation taking place on the building’s exterior. For those not from the area, here’s a look at the transformation:

What’s Next on the Schedule for Stratix:

Once the new exterior insulation finish system is complete, we will then begin to stencil the brick. The stenciled brick will nicely compliment the other buildings of the Knitting Mills across the street. Here are some photos from a mock up that was completed last August by Paramount Contracting Inc. to give you an idea of what the final exterior will look like:

D&B Construction also looks forward to hosting our first topping off ceremony to commemorate the completion of the steel work for this building in May. “This long-standing tradition of construction workers commemorates the completion of the buildings structure as the final beam is placed,” explains Chief Executive Officer of D&B Construction, Dan Gring. “We are happy and excited to be part of projects such as this one that will revitalize such a vital, historic building. The fact that our first topping off ceremony just so happens to be in the hometown of where it all began for our company, where many of our team members not only work but live, is just the icing on the cake. It’s a true honor,” he states.

D&B Construction’s partnership with Earth Engineering Incorporated dates back eight years to 2014. They have completed over 12 projects with D&B Construction since becoming our Trade Partner. These projects range from large multi-family projects on 50 acres of land to large healthcare projects for clients like Tower Health and Children’s Hospital of Philadelphia.

EEI performed numerous services on these projects including compaction testing, concrete testing, geotechnical consulting, sinkhole remediation, structural steel inspection, geotechnical investigations, clean fill assessment, and design services. Paul J. Creneti, P.G., Director of the Lehigh Valley division of Earth Engineering Incorporated, has been part of the industry for 26 years now. “Working on these projects with D&B Construction was fulfilling, as they were a collaborative effort with the construction and design team,” he reflects.

Paul has worked with many members of Team D&B over the years, including our Chief Operating Officer Brennan Reichenbach, Vice President of Pre-Construction Mark Keever, Project Manager Scott Weaver, and Vice President of Construction for Reading and Central PA, Tom Rinaldo. His favorite part of working on a D&B project? “Being part of a project team that has trust with all parties involved.” Paul can count on the fact that “quality would never be an issue” whenever he works with Team D&B. “If problems arose during development, the team handled these problems quickly and most appropriately to ensure that sites were being developed properly.”

According to our VP of Construction Tom Rinaldo, who has worked with Paul and EEI for the last 15 years on various projects, “they bring undeniable value and knowledge to D&B projects as a valued Trade Partner.” Tom most enjoys how knowledgeable their geologists are. “We utilize them to do proctors for us. They help out in a variety of ways, from testing and analysis of soil on job sites to concrete testing. When we completed work for 999 Berkshire Blvd. we had to excavate and remove 10,000 SF of soil and excavated around the entire exterior of the building to remediate soils. Their team’s analysis of the unsuitable soil and assistance in finding suitable soil was imperative to the success of this project.”

About Earth Engineering Incorporated:

This full service geotechnical / environmental engineering consulting firm was founded in 1990 in Blue Bell, Pennsylvania. By 2003, EEI outgrew this facility and established their Corporate Headquarters in East Norriton, Pennsylvania. Today they have approximately 125 employees and other regional offices in West Berlin, New Jersey, the Lehigh Valley and Central Pennsylvania that allow them to service projects from New York to Maryland.

EEI provides their clients with geotechnical engineering and environmental consulting services. Such services allow them to contribute to the successful development of a wide variety of projects for their clients, as issues such as cost-effectiveness and site development issues are evaluated by their team. This analysis allows EEI to provide clients with the best recommendations on how to proceed with their project.

The predominance of their geotechnical and environmental work is in the private commercial and residential sectors, with a portion of their geo-structural design work in the public sector. EEI takes on approximately 1,200 new projects within a year.

Q&A With Paul Creneti, Director of EEI’s Lehigh Valley Division:

Q: What’s the best piece of advice you would give to others looking to get into the industry?

A: “Listen to your client’s needs while at the same time keeping the project within or below budget. You can accomplish this through quality engineering and quick decisions.”

Q: What makes a good leader?

A: “Being true to your corporate values and goals and holding a high standard for others to follow.”

Q: What do you love most about your job and why?

A: “Being part of a project team that leads to the successful completion of projects despite countless variables along the way. It’s rewarding.”

Q: What about a D&B project stands out in comparison to other General Contractors you work with on other job sites?

A: “Quality with a strong focus on the client’s needs.”

A Look at Some of the Jobs EEI and D&B Have Successfully Worked on Together Over the Years:

Projects Currently Under Construction:

The Reserve at Iroquois Springs

EEI’s Geotechnical Engineer, Dan, was just on site last week to check the compaction rating of the soil on this jobsite. View some recent drone footage here.

Completed Projects:

Cardiology Consultants of Philadelphia – Paoli, PA Location

Bucks County Orthopedic Specialists – Warrington, PA Location

Tower Health Medical Group Family Medicine – Womelsdorf, PA Location

Riverfront Federal Credit Union

Paramount Contracting, Inc., a commercial wall and ceiling contractor, is based out of Lancaster, PA and serves the Pennsylvania, New Jersey, Delaware, West Virginia, Virginia, and Maryland areas. The company was established as a premier wall and ceiling contracting company by Jeff Mylin in 2005. “The emphasis was always on customer service and building a great team,” says a reflective Mylin 16 years later. “We focused on the needs of the customer and providing an end product that our team would be proud of.” As a result of this, Paramount has “experienced organic growth as opportunities presented themselves over the years.” Today, the company has nearly 100 employees, completes in excess of 300 jobs per year, and specializes in Metal Studs, Drywall, Insulation, EIFS and Acoustical Ceilings, as well as select Carpentry and Specialty items.

D&B is proud to have been partnering with a company that reciprocates our core values of being a company that cares about everything from the customer to the finished product. Since Paramount became a Trade Partner of D&B Construction’s nearly five years ago in 2017 they have worked on more than 10 projects with us, completing everything from insulation, drywall, and exterior sheathings to rough blocking, acoustical ceilings and clouds, and FRP.

Some of the current active projects Paramount is working on with D&B include this mixed-use design-build project in Kennett Square, PA, D&B’s new corporate headquarters, and Kreitz Gallen-Schutt Attorney’s office fit out, which is just starting up. Other projects worth highlighting from this year include Tower Health’s newest satellite office in Womelsdorf and Grove Dental Pediatrics.

Perhaps the most impressive job that Paramount is working on D&B with is the 80,000 SF adaptive reuse building currently being renovated in the heart of Wyomissing. This five-story building will be the future home of Stratix Systems’ headquarters.

Our Project Manager, Andrew, plays an active role in the daily management of what is occurring at the jobsite. This is what he had to say about his experience working with their team on this job: “Paramount has been an integral Trade Partner on our project at 200 N. Park Road in Wyomissing. Their Project Managers and Site Foreman have brought knowledge from previous projects on nearby, similar style buildings that have aided our project in design, constructability and schedule. Their crews have been more than accommodating with a stubborn building that has required much coordination and numerous details from the Architect.”

Andrew also had the pleasure of working with Paramount on three other projects, including his first job with D&B nearly one year ago, Kingsview Partners. He looks forward to “continuing our strong relationship with such a great Trade Partner” as we head into completing more jobs with them in the New Year.

Oh, and did we mention the Paramount team has some pretty great cooks, too?! This past October, Paramount was kind enough to host a home-cooked BBQ luncheon at Stratix Systems’ future new headquarters for all D&B employees, ownership, the project architect, RHJ Associates, and even invited us to invite other Trade Partners on the job. It was a great day of camaraderie onsite as we all learned about the intricate details of this detailed project. “Their BBQ was the launching point for one of our company’s on-site safety training sessions, and attendance was most definitely enhanced as a result of the promise of good food. We were and still are grateful for their efforts,” reflect Andrew.

We sat down with Jeff Mylin, President of Paramount Contracting, for a quick Q&A:

Q: Paramount Contracting has completed 4,100 jobs since its inception. What project are you most proud of to date and why?

A: “It is hard to choose just one, but the Ann B. Barshinger Cancer Institute in Lancaster, PA would be near the top. It is a respected facility in our home town and architecturally impressive building.”

Q: What’s the best piece of advice you would give to others looking to get into the industry?

A: “You have to have a love for the industry. Construction is a tough business with demanding schedules, tight budgets and currently material and labor shortages. Yes, there are many challenges but it also can be very rewarding when seeing the job come to completion. Those of us in this line of work understand how it feels to drive by a finished project and feel a sense of pride that ‘we helped build that.’”

Q: You are completing a number of projects with D&B right now. What has your experience been like working with our team?

A: “D&B projects are clean, organized, and safe projects to work on. They communicate clearly with all of the trade teams, which leads to successful projects. We have made a significant investment into bidding to D&B and we feel that has not gone unnoticed. Subcontractor loyalty is obvious, which increases effective teambuilding.”

Q: What do you enjoy most about working on a D&B project and why?

A: D&B Superintendents, Project Managers, Engineers, and support/admin staff are always accessible and willing to help. Coordination and scheduling are always well thought out and communicated from planning to completion. The jobs are often local, and our employees enjoy investing in the buildings in their community.”

At D&B Construction we like to think of our trade partners as an extension of our team. We are proud to call Paramount Contracting an extension of the D&B family. Every project we have collaborated with them on results in a final product that both teams can be proud of and that our customers can look forward to.

Technology is ever-evolving, and part of this evolution includes the construction industry. In response to COVID-19 and technological advancements, the construction industry has begun to innovate more than ever before. One of the most fascinating practices that is growing in popularity is modular or off-site construction.

Modular or offsite construction is the process in which a building is constructed off-site under controlled conditions using the same materials and built to the same standards as conventionally built facilities. The only difference? It can be built in nearly half the time. Buildings are constructed in modules that can be put together to form the original design, all while still resembling the work of the most sophisticated site-built facility. Why do companies use modular construction? The answer is simple. Modular construction is greener, faster, and safer.

A Greener World with Modular Construction

Since modular construction is a factory-controlled process it generates less waste and creates a site that is less likely to evoke disturbances. A modular construction site also promotes more flexibility and re-use. Modular projects can be disassembled and relocated or refurbished for new use. This reduces the demand for materials and limits the amount of energy used to create a building that meets the new needs. Additionally, a modular site produces less material waste since the building is constructed in a factory and waste is eliminated by recycling material, controlling inventory, and protecting building materials.

Finish Projects in Record Time

Modular construction is also faster than traditional building methods. Construction of modular buildings occur while site and foundation work are both being done. The Modular Building Institute reports that this can reduce construction times by 30%-50%. This can also be credited to the elimination of weather delays. Sixty to ninety percent of construction is completed inside of a factory, leaving no need to worry about inclement weather delaying a project.

Staying Safe with Modular Construction

One of the most important benefits of modular construction is safety. As we know, safety is always a priority in construction, and modular building makes it easier than ever to be safe. A report by McGraw-Hill Construction found that over 1/3 of their respondents (34%) who are currently using modular construction have seen site safety improve. This may be credited to the fact that it is free from weather elements like rain or snow that can cause slips and falls. It also reduces the risk of a worker falling from great heights, which OSHA reports as the cause of 33.5% of construction worker fatalities. Learn more about OSHA and their dedication to safety by reading this article on D&B Construction’s blog.

Modular Construction: How It’s Done

Modular building is done mostly on the ground level, but if working from height is required permanent scaffolding is used. This permanent scaffolding is different (and safer) from the scaffolding normally used on a traditional job site. Because it is not constantly being moved and reassembled, there is less likelihood for error and accidents.

Modular construction is growing in popularity. According to Fortune Business Insights, the global modular construction market is going to be valued at $114.78 billion USD by 2028. The market was valued at $72.11 Billion USD in 2020. Here are some examples of just how much you can do with modular construction:

Star Apartments, Los Angeles, 2014

The Star Apartments in Los Angeles were built in 2014 on top of a previously existing single-story commercial building. A concrete superstructure was poured over the existing structure. Next, five stories of modules that were built off-site were added on top of the single-story commercial building. The modules were stucco-finished on site. These modules provide 102 apartments and have pre-installed bathrooms, appliances, cabinets, and surface finishes.

Habitat 67, Montreal, 1967

An iconic example of modular construction is Habitat 67. Built in 1967, architect Moshe Sadfie’s unique cuboid block of 158 apartments caught the eyes of many. The way Sadfie designed Habitat 67 allowed for 15 different kinds of housing, gardens and terraces to fill the voids in between. The complex stack of concrete houses was connected by high-tension rods, steel cables, and welding. Even though it was built in 1967, Habitat 67 shows the true possibilities of modular construction.

Nakagin Capsule Tower, Tokyo, 1972

This 14-story tower was the world’s first example of permanent modular construction. The building has 140 self-contained, prefabricated concrete capsules that each measure 2.3m x 3.8m x 2.1 m. The capsules were each connected to the shaft of the building with just four high-tension bolts, allowing each unit to be replaceable if needed. These capsules were delivered to the site already fitted out with a small bathroom. Owners used the capsules as small living or office spaces, and the interior space of each module can even be extended by connecting to other capsules.

These are three unique examples of modular construction because of their structure. While these extravagant and unique designs are made easier with modular construction, you can also make very basic structures that look identical to buildings that are constructed on-site. The possibilities with modular construction are seemingly endless thanks to its ability to make construction greener, faster, and safer. We look forward to seeing just how far modular construction will go.

Our first Trade Partner Spotlight features Gillespie Electric, Inc. Located in East Greenville, PA this full-service electrical contracting company has been a recognized industry leader known for its reliability for over 40 years.

We recently drove out to Souderton, PA to check out the new 12,500 SF community health center quickly taking shape for the Children’s Hospital of Philadelphia. Every time we visit we are greeted by the smile of D&B’s Superintendent on the jobsite, John. He always has a positive energy about him, but when we visited on June 23rd he was literally excited to show us the work that Gillespie Electric, Inc. just completed. We’ll show you as well so you can see what John was talking about:

Although new to Team D&B, John has been in the industry working on a variety of large construction projects over the last 34 years (including the delicious Steak 48 on Broad Street in Philadelphia). John described the work the Gillespie team completed as a “quality standardized performance” and claimed he has never seen such well-executed work from electricians. “This demonstrates the quality and care that these guys have to make this job beautiful,” says John with a smile as he admires their work once more.

According to Gillespie Electric’s Project Manager, Keith Lewis, who has worked on this healthcare project with D&B Construction since it began, they “have been on and off site since this project first broke ground last year and will be on site until the job is complete in a few months.” Over 350 receptacles and 15,000 linear feet of HFC Hospital grade MC are being installed on this project. “All of the lights are LED and we are installing a back-up generator for all of the vaccine refrigerators,” explains Keith.

The company’s Foreman, Mike, as well as Nick (who John admiringly refers to as “another badass” on the Gillespie team) just recently finished tying everything into the panels, a job that took about a week to complete. “Mike and Nick both completed two different rooms. A lot of times when you have two electricians on the same job you can notice slight differences, but their work looked identical. I couldn’t even tell who did which room since their work was so precise,” says John.

The Foreman, Mike, has been with Gillespie for 10 years since 2011 and received his Electrical Apprenticeship from Bucks County Tech in 2012. Keith, who sings high praises of his co-worker, says that Mike was a journeyman for nine years and became a Foreman at the company last year. “Interestingly enough, this job is Mike’s first job that he is completing from start to finish as a Foreman. It’s not every day you win both the core and shell and fit-out phases and are able to be involved in the entire project.”

Although Gillespie has completed a number of jobs for CHOP over the years, this is the first job they are completing for D&B. “There are always some challenges when working with a new general contractor,” says Keith. “It’s like when you first start a new job. You have to feel out your new boss, and they are doing the same with you. But we have had very minimal challenges working with D&B. Communication has been easy, and working with Jim (D&B Project Manager on the job) has been easy, too. It honestly feels like we have been working with them for much longer than we have.”

Keith had similar remarks to say about our Superintendent on the job. “John is on top of things. He gets questions answered efficiently and makes good, on-his-feet decisions. If I ask John a question, I know I will have the answer within a day or two. That’s unusual. Construction should be fluid, and he makes it that way,” says Keith.

At D&B, we view our trade partners as an extension of our team. That’s why we work with trusted trade partners like Gillespie Electric who bring the same level of care that we do to the jobsite.

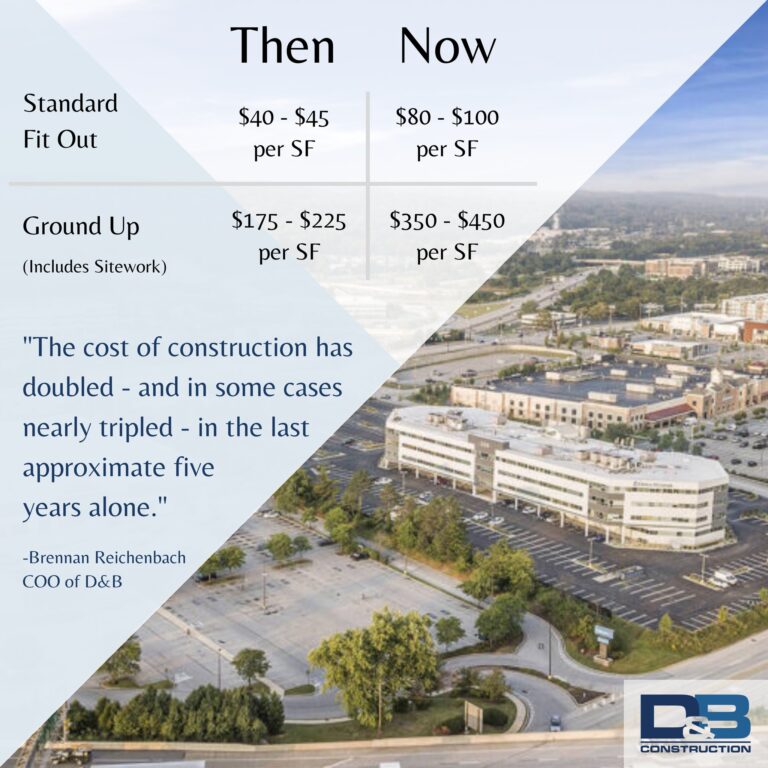

If you are even remotely connected to the construction world, talking to you Mr. and Mrs. weekend DIY’er, you have heard about the current state of construction material costs. Last week lumber hit a new all time high of $1,188 per thousand board feet, nearly a 250% increase from the same time last year. The worst part? Prices are expected to climb further through the remainder of the building season. Steel products, if you can find them, have also doubled in pricing over the last six months. This perfect storm of sky-rocketing costs has forced contractors, developers, business and home owners, suppliers and everyone else in the supply chain to adjust. Some are hoarding materials while others just hit the pause button. Ground-up construction for the remainder of 2021 looks to be a big question mark for everyone. However, one sector is proceeding full steam ahead; adaptive reuse.

Adaptive reuse, historically, has been seen as an eco-friendly construction practice that “recycles” existing structures through a conversion of it’s intended use into something new. In Baltimore, the old Pratt Street Power Plant was converted into retail and restaurants. In Philadelphia the Independence Press Building, a paper box production facility, is now a 92-unit apartment building. You can find incredible examples throughout the world of converted buildings getting new life through reincarnation. Given the current construction climate due to soaring costs, the green tint of adaptive reuse isn’t coming from the ingrained environmental benefits. It’s coming from money.

Developers who have long valued the environmental impact of reusing or repurposing a building are finding new returns on their investments. The financial benefits speak for themselves. Cost savings are everywhere in adaptive reuse. Obviously, it takes a lot less material reusing an existing structure than building a new one out of the ground. Beyond that, savings are coming in the way of demolition costs, design and approvals, and time, which is commonly overlooked. Other non-monetary benefits include preserving a community identity, enhancing local accommodations and offerings, economic and environmental sustainability, among others. It is no surprise why adaptive reuse is getting so much attention.

Fortunately for D&B Construction Group, there are a few of these projects in pre-construction and under construction currently. The Metropolitan Edison Building, once the tallest building in Reading, Pennsylvania, is a prime example of adaptive reuse. This 14-story brick building is being converted into market rate apartments to answer growing demand for modern urban multi-family living. A stone’s throw up Washington street is another adaptive reuse project that will start this summer. The Berkshire Building, originally a hotel then converted into office space, prepares for new life as student housing supporting Alvernia University’s new Collegetowne campus. The projects have been a boon for D&B. Dan Gring, D&B Construction Group CEO, recently reflected on the downtown Reading, PA projects:

“To have these large projects that are filling a need in the community, creating a good business venture for our clients, and providing the company with steady and reliable work is invaluable. There’s a lot of speculation and analysis between us, our clients, vendors, and so on with new construction projects that has many people in our industry worried. Luckily for us, we’ve built a wide range of clients who trust us with their projects, and we’re fortunate that several of them focus on adaptive reuse projects. We know with relative certainty that material costs are not jeopardizing those jobs.”

Environmentally sustainable, financially conscious, and preserving communities. It’s a winning solution all the way around in the current construction market. Whether or not adaptive reuse projects see a spike as a result of the pandemic fallout or not remains to be seen. In the short-term companies like D&B and our clients will continue to reap the benefits of this construction approach.

— Drew Bell, VP of Business Development

Drew Bell, of Wyomissing, brings over 10 years of marketing and business development experience to D&B Construction Group. Prior to joining the team in March of 2020, Drew served as the Business Development Officer at Tompkins VIST Bank. He was also the President of the Reading Royals professional hockey team for three years. Drew is a strong believer that “genuine opportunities come from trust based on knowledge and sincerity.” His dedication to creating and strengthening mutually beneficial partnerships to make collective solutions and his contagious, positive attitude make him not only a huge asset to our team, but a well-respected individual throughout the communities we serve.

Drew graduated from Penn State University with a Bachelor’s Degree and received his J.D. from Widener Law School. Active in the community, he is a member of the Berks and Pennsylvania Bar Associations and a committee member for Berks Catholic High School. He previously held board positions with the Greater Reading Convention and Visitors Bureau, as well as the Gilmore Henne Community Fund, Boy Scouts of America Hawk Mountain Council, and Salvation Army of Reading.

Born and raised in Wayne, PA, a suburb of Philadelphia, Drew relocated to Reading in 2010 with his wife, Maryanne Post, after the two graduated Law School. Drew and Maryanne live in Wyomissing with their three kids Charlotte, Amelia and Scotty. In his free time Drew loves to golf and be outdoors.