Safe + Sound is a year-round campaign to encourage every workplace to have a safety and health program. It was launched by OSHA in an effort to gain safety awareness. Every year in August, OSHA has a Safe + Sound week, with this year’s taking place from Monday, August 9th to Sunday, August 15th.

This nationwide event recognizes the success of workplace health and safety programs and offers information and ideas on how to keep America’s workers safe. Seven businesses make up the list of organizers who participate in planning calls, working collaboratively with each other to develop and review Safe + Sound materials and communications, and leverage their own resources to support these efforts. In addition to OSHA, these businesses include large organizations, such as the National Safety Council and . The program also has 225 partners who are membership organizations that are responsible for communication and outreach throughout the year to promote Safe + Sound to their stakeholders.

D&B Construction is one of 68 companies throughout PA (and over 1,600 across the nation) who have signed up to participate in Safe + Sound Week 2021. We are excited to show our support and commitment to continue building safer jobsites. People come first at D&B. The safety of our employees, trade partners, and clients is always paramount in every project’s preparation and execution. In order to make this happen, safety and health are at the core of everything we do. Learn how here.

The Occupational Safety and Health Administration, better known as OSHA, was created in 1970 to ensure safe and healthy working conditions by setting and enforcing safety standards in addition to providing training, outreach, education, and assistance. You may have heard OSHA refer to the “Fatal Four” when describing the four most common causes of worker deaths on construction sites throughout the United States.

The four most common causes of worker deaths in this industry come from Falls,) which account for 33.5% of construction worker deaths), being struck by an object (11.1%), electrocutions (8.5%) and being caught in / between something accounted for 5.5% of construction worker deaths. According to OSHA, as of 2020 “one in five worker deaths in 2019 were in construction.” The “Fatal Four” were responsible for more than half (58.6%) of construction worker deaths. According to OSHA, if these “Fatal Four” causes could be eliminated, they would save 591 workers’ lives in America each year.

In 2020, OSHA gathered data on the top 10 instances of safety code violations. Learn what they are below, and hear from our Director of Construction and Safety Director, Tom, on how such issues can be avoided and prevented:

1. Inadequate Fall Prevention – 6,010 violations

What This Means: OSHA states that a violation could include not providing working conditions that are free of known dangers, failure to keep floors in work areas in a clean and dry state, as well as not providing required personal protective equipment at no cost to workers.

Tips on How to Prevent This: Our Safety Director, Tom, encourages the use of safety rails and body harnesses on every job site. “At D&B we provide these on every job site to give our workers the safest environmental possible.”

2. Inadequate Hazard Communication – 3,671 violations

What This Means: Simply put, this refers to the failure to inform all people on the job site of potential risks and hazards.

Tips on How to Prevent This: “At D&B we fill out a Job Safety Analysis (JSA) and Job Hazard Analysis (JHA) on all job sites,” explains Tom. “This helps us to ensure that we are communicating this vital information with all of our employees and trade partners. Communication is huge in enhancing safety.”

3. Unsafe Scaffolding – 2,813 violations

What This Means: Failure to abide to OSHA standards would include improper fall protection / fall arrest systems, unsuitable guardrail height, inadequate footing support, failure to complete inspections, etc.

Tips on How to Prevent This: Work with reputable scaffolding companies that you trust. “At D&B we complete daily and weekly inspections on the scaffolding on our site to ensure we are practicing proper scaffolding safety protocols,” says Tom.

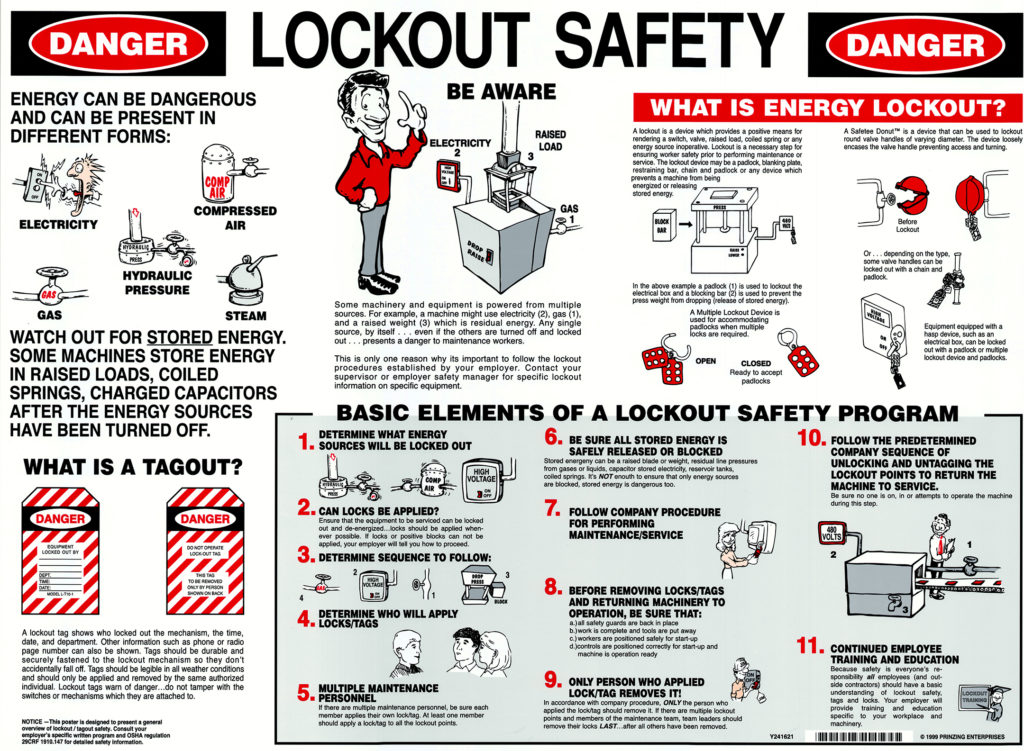

4. Failure to control hazardous energy (Lockout / Tagout Violations) – 2,606 violations

What This Means: Failure to address the practices and procedures needed to disable machinery or equipment that may expose workers to hazardous energy.

Tips on How to Prevent This: “There is no better way to ensure this mishap is avoided then by requiring all electricians on your job site to use lockout and tagout procedures on all powered equipment and panel boxes,” says Tom.

At D&B, we include the following lockout safety poster on our Safety Board at all jobsites:

5. Inadequate Respiratory Protection – 2,450 violations

What This Means: A violation would include not providing the proper respiratory protection.

Tips on How to Prevent This: “In addition to providing dust masks to all employees, it is important to utilize clean air machines and air scrubbers such as HEPA filters on your job sites,” says Tom. “In any situation where there are environmental hazards present, we as a company will hire a reputable remediation company to ensure the safety and health of all people on the job site. I highly recommend doing this when the elements require it.”

6. Unsafe Ladders – 2,345 violations

What This Means: This could include placing a ladder on a box or barrel, using ladders where there is unstable footing or soft ground, exceeding a ladder’s maximum load rating, ignoring nearby overhead power lines, moving or shifting the ladder while a person or equipment is on it, using an extension ladder horizontally as a platform, etc.

Tips on How to Prevent This: “Have your Site Superintendents check ladders on a daily and weekly basis. If any ladders are deemed unsafe or defective, they should be removed immediately,” says Tom. Unlike hard hats, for example, there is no specific expiration date for ladders. Following proper storage techniques and treating ladders with care can help in making them last longer.

7. Powered Industrial Truck Safety Violations – 2,093 violations

What This Means: This refers to improper vehicle use, lack of training, and a failure to re-certify operators every three years as required.

Tips on How to Prevent This: ” At D&B, we make sure all of our Pettibone and Lift operators are certified, and we require lift plans for any kind of crane lifts. This is something I recommend everyone get in the habit of making a standard practice.”

8. Inadequate Fall Prevention & Training Requirements – 1,773 violations

What This Means: Failure to provide proper fall prevention training is something that can easily be avoided if proper training and communication on fall prevention is completed on all job sites.

Tips on How to Prevent This: “All D&B Construction field personnel are OSHA certified, and we also hold training sessions throughout the course of the year,” explains Tom.

At D&B, we include the following fall protection poster on our Safety Board at all jobsites. This is an easy way to remind everyone on the job site of how to best prevent falls.

9. Unsafe Machinery and Inadequate Machine Guarding – 1,743 violations

What This Means: Failure to provide one or more methods of machine guarding to ensure the safety of the operator and others in the nearby area can result in an unsafe job site.

Tips on How to Prevent This: “All powered tools are inspected for proper and adequate guarding by a D&B employee, such as the Site Superintendent, before use,” says Tom.

10. Inadequate Personal Protective and Lifesaving Equipment, Eye and Face Protection – 1,411 violations

What This Means: Failure to make the appropriate personal protective equipment available to all employees at no cost is something that should not occur anywhere.

Tips on How to Prevent This: “Keep inventory of safety equipment, such as safety glasses and hi-visibility vests, for all of your employees. At D&B, we keep a document that is updated every time a new hire starts so we know the date in which they received all of their issued PPE. This makes it easy for us to keep taps on when hard hats will expire and new ones will need to be re-issued. We also provide respiratory and hearing protection on every job site.”

According to the U.S. Bureau of Labor Statistics, the construction industry had 195,600 workplace injuries and 3,600 workplace illnesses in 2019. More specifically, Pennsylvania’s non-fatal workplace injury and illness rates were above the national average. The Center for Construction Research and Training’s Fatality Map Dashboard also shows that since data started being collected in 2011, Delaware has had 17 fatal injuries in construction, New Jersey has had 145, and Pennsylvania has had 213 fatal injuries. With these statistics in mind the importance of practicing safety is pretty clear.

“Safety Weeks such as this one exist so we can create awareness and reduce the number of fatalities our industry sees,” concludes Tom. “Chances are that some of the fatalities seen could have been prevented if better communication and more training took place. That’s why our team at D&B is focused on achieving safety every day through daily safety checks on site.”

Let us know how you work to prevent incidents on the job site in the comments below, and consider joining D&B and thousands of other companies in taking the pledge to be Safe + Sound – both throughout this week and every day.