D&B Construction’s partnership with Quality Buildings, a commercial framing contractor, began this year through their work on Kennett Pointe, a ground-up mixed-use property currently under construction in Kennett Square, PA.

Elmer Zook, Founder and President of Quality Buildings, has been part of the industry for 18 years now. “We like expanding our client base as well as building new relationships in the construction industry. D&B came on our radar a few years ago as a fast-growing player amongst other GC’s,” he reflects.

The fruition of Quality Buildings’ relationship with D&B began as a culmination of a handful of work connections, including having known our CEO, Dan Gring, through their involvement at Lancaster Berks Next Gen Construction Connect. At Kennett Pointe they supplied a complete furnish and installed a framing package that included manufacturing of pre-fabricating wall panels, floor and roof trusses and installation of the windows and doors.

“Quality Building produces quality work, and they are easy to communicate with. It is always a pleasure working with them, and I would work with them again in a heartbeat,” says John Ruza, Senior Superintendent overseeing the jobsite in Kennett Square.

About Quality Buildings:

This turnkey framing contractor was founded in 2008 as a home improvement contractor and Agricultural/Equestrian facilities design and build contractor. They’ve built many custom designed horse barns and riding arenas in NY, NJ, DE, MD, and VA.

Having experience in design and build as a contractor, coupled with a desire to work closer to home versus constant traveling, commercial framing seemed to fit well with their philosophy of working together as a team with other trades to deliver a well-planned project. In 2014, their sole focus became commercial framing for multi-family apartments, senior living and hotels. Completing between 12-15 projects annually, the company has an annual gross revenue of $20,000,000+ in the multi-family, senior living and hospitality sectors. Quality Buildings started pre-fabricating wall panels out of their own facility and continued to expand.

Today, Quality Buildings specializes in offsite pre-fabricated building components, as well as framing components, wall panels, floor trusses, roof trusses and all needed equipment and labor for a complete framing system. Offering VE options and full 3D modeling capabilities for clash detection, as well as BIM modeling with other trades, they are acknowledged as a leading innovator in wood framing. They also offer structural engineering and Mass Timber construction. Their commitment to provide customers with the finest craftmanship continues to be their anchor 14 years later. Quality Buildings has an employee count of 42, consisting of VDC designers, project managers, pre-fabricated wall panel manufacturing and field carpenters. They also have a steady base of subcontractors they know they can turn to for their larger projects.

“We pride ourselves for having more attention to detail and a higher level of service than our competition,” explains Elmer. “We are the experts in wood framing and strive to present ourselves as such. Every department within Quality Buildings has an in-depth knowledge of wood framing. Our designers are the linchpin of our projects being successful and have an extensive hands-on experience with building these projects in the field.”

Q&A With Elmer Zook, Founder and President of Quality Buildings

Q: What’s the best piece of advice you would give to others looking to get into the industry?

A: “Learn as much as you can about the trade you are a part of and about the trades around you that need your collaboration to do a good job and offer a stellar service. Care about your craft and treat people with respect.”

Q: What do you love most about working in the industry and why?

A: “I love working in the industry and providing a service that goes above and beyond just showing up and swinging a hammer. I love that our team is intentional about getting into the nuts and bolts of a project and finding new and better ways to get the job done.”

Q: Anything else you’d like to add?

A: “We appreciate D&B entrusting QB with being your Framing partner on this project and look forward to many more in the future.”

D&B Construction’s partnership with Earth Engineering Incorporated dates back eight years to 2014. They have completed over 12 projects with D&B Construction since becoming our Trade Partner. These projects range from large multi-family projects on 50 acres of land to large healthcare projects for clients like Tower Health and Children’s Hospital of Philadelphia.

EEI performed numerous services on these projects including compaction testing, concrete testing, geotechnical consulting, sinkhole remediation, structural steel inspection, geotechnical investigations, clean fill assessment, and design services. Paul J. Creneti, P.G., Director of the Lehigh Valley division of Earth Engineering Incorporated, has been part of the industry for 26 years now. “Working on these projects with D&B Construction was fulfilling, as they were a collaborative effort with the construction and design team,” he reflects.

Paul has worked with many members of Team D&B over the years, including our Chief Operating Officer Brennan Reichenbach, Vice President of Pre-Construction Mark Keever, Project Manager Scott Weaver, and Vice President of Construction for Reading and Central PA, Tom Rinaldo. His favorite part of working on a D&B project? “Being part of a project team that has trust with all parties involved.” Paul can count on the fact that “quality would never be an issue” whenever he works with Team D&B. “If problems arose during development, the team handled these problems quickly and most appropriately to ensure that sites were being developed properly.”

According to our VP of Construction Tom Rinaldo, who has worked with Paul and EEI for the last 15 years on various projects, “they bring undeniable value and knowledge to D&B projects as a valued Trade Partner.” Tom most enjoys how knowledgeable their geologists are. “We utilize them to do proctors for us. They help out in a variety of ways, from testing and analysis of soil on job sites to concrete testing. When we completed work for 999 Berkshire Blvd. we had to excavate and remove 10,000 SF of soil and excavated around the entire exterior of the building to remediate soils. Their team’s analysis of the unsuitable soil and assistance in finding suitable soil was imperative to the success of this project.”

About Earth Engineering Incorporated:

This full service geotechnical / environmental engineering consulting firm was founded in 1990 in Blue Bell, Pennsylvania. By 2003, EEI outgrew this facility and established their Corporate Headquarters in East Norriton, Pennsylvania. Today they have approximately 125 employees and other regional offices in West Berlin, New Jersey, the Lehigh Valley and Central Pennsylvania that allow them to service projects from New York to Maryland.

EEI provides their clients with geotechnical engineering and environmental consulting services. Such services allow them to contribute to the successful development of a wide variety of projects for their clients, as issues such as cost-effectiveness and site development issues are evaluated by their team. This analysis allows EEI to provide clients with the best recommendations on how to proceed with their project.

The predominance of their geotechnical and environmental work is in the private commercial and residential sectors, with a portion of their geo-structural design work in the public sector. EEI takes on approximately 1,200 new projects within a year.

Q&A With Paul Creneti, Director of EEI’s Lehigh Valley Division:

Q: What’s the best piece of advice you would give to others looking to get into the industry?

A: “Listen to your client’s needs while at the same time keeping the project within or below budget. You can accomplish this through quality engineering and quick decisions.”

Q: What makes a good leader?

A: “Being true to your corporate values and goals and holding a high standard for others to follow.”

Q: What do you love most about your job and why?

A: “Being part of a project team that leads to the successful completion of projects despite countless variables along the way. It’s rewarding.”

Q: What about a D&B project stands out in comparison to other General Contractors you work with on other job sites?

A: “Quality with a strong focus on the client’s needs.”

A Look at Some of the Jobs EEI and D&B Have Successfully Worked on Together Over the Years:

Projects Currently Under Construction:

The Reserve at Iroquois Springs

EEI’s Geotechnical Engineer, Dan, was just on site last week to check the compaction rating of the soil on this jobsite. View some recent drone footage here.

Completed Projects:

Cardiology Consultants of Philadelphia – Paoli, PA Location

Bucks County Orthopedic Specialists – Warrington, PA Location

Tower Health Medical Group Family Medicine – Womelsdorf, PA Location

Riverfront Federal Credit Union

Paramount Contracting, Inc., a commercial wall and ceiling contractor, is based out of Lancaster, PA and serves the Pennsylvania, New Jersey, Delaware, West Virginia, Virginia, and Maryland areas. The company was established as a premier wall and ceiling contracting company by Jeff Mylin in 2005. “The emphasis was always on customer service and building a great team,” says a reflective Mylin 16 years later. “We focused on the needs of the customer and providing an end product that our team would be proud of.” As a result of this, Paramount has “experienced organic growth as opportunities presented themselves over the years.” Today, the company has nearly 100 employees, completes in excess of 300 jobs per year, and specializes in Metal Studs, Drywall, Insulation, EIFS and Acoustical Ceilings, as well as select Carpentry and Specialty items.

D&B is proud to have been partnering with a company that reciprocates our core values of being a company that cares about everything from the customer to the finished product. Since Paramount became a Trade Partner of D&B Construction’s nearly five years ago in 2017 they have worked on more than 10 projects with us, completing everything from insulation, drywall, and exterior sheathings to rough blocking, acoustical ceilings and clouds, and FRP.

Some of the current active projects Paramount is working on with D&B include this mixed-use design-build project in Kennett Square, PA, D&B’s new corporate headquarters, and Kreitz Gallen-Schutt Attorney’s office fit out, which is just starting up. Other projects worth highlighting from this year include Tower Health’s newest satellite office in Womelsdorf and Grove Dental Pediatrics.

Perhaps the most impressive job that Paramount is working on D&B with is the 80,000 SF adaptive reuse building currently being renovated in the heart of Wyomissing. This five-story building will be the future home of Stratix Systems’ headquarters.

Our Project Manager, Andrew, plays an active role in the daily management of what is occurring at the jobsite. This is what he had to say about his experience working with their team on this job: “Paramount has been an integral Trade Partner on our project at 200 N. Park Road in Wyomissing. Their Project Managers and Site Foreman have brought knowledge from previous projects on nearby, similar style buildings that have aided our project in design, constructability and schedule. Their crews have been more than accommodating with a stubborn building that has required much coordination and numerous details from the Architect.”

Andrew also had the pleasure of working with Paramount on three other projects, including his first job with D&B nearly one year ago, Kingsview Partners. He looks forward to “continuing our strong relationship with such a great Trade Partner” as we head into completing more jobs with them in the New Year.

Oh, and did we mention the Paramount team has some pretty great cooks, too?! This past October, Paramount was kind enough to host a home-cooked BBQ luncheon at Stratix Systems’ future new headquarters for all D&B employees, ownership, the project architect, RHJ Associates, and even invited us to invite other Trade Partners on the job. It was a great day of camaraderie onsite as we all learned about the intricate details of this detailed project. “Their BBQ was the launching point for one of our company’s on-site safety training sessions, and attendance was most definitely enhanced as a result of the promise of good food. We were and still are grateful for their efforts,” reflect Andrew.

We sat down with Jeff Mylin, President of Paramount Contracting, for a quick Q&A:

Q: Paramount Contracting has completed 4,100 jobs since its inception. What project are you most proud of to date and why?

A: “It is hard to choose just one, but the Ann B. Barshinger Cancer Institute in Lancaster, PA would be near the top. It is a respected facility in our home town and architecturally impressive building.”

Q: What’s the best piece of advice you would give to others looking to get into the industry?

A: “You have to have a love for the industry. Construction is a tough business with demanding schedules, tight budgets and currently material and labor shortages. Yes, there are many challenges but it also can be very rewarding when seeing the job come to completion. Those of us in this line of work understand how it feels to drive by a finished project and feel a sense of pride that ‘we helped build that.’”

Q: You are completing a number of projects with D&B right now. What has your experience been like working with our team?

A: “D&B projects are clean, organized, and safe projects to work on. They communicate clearly with all of the trade teams, which leads to successful projects. We have made a significant investment into bidding to D&B and we feel that has not gone unnoticed. Subcontractor loyalty is obvious, which increases effective teambuilding.”

Q: What do you enjoy most about working on a D&B project and why?

A: D&B Superintendents, Project Managers, Engineers, and support/admin staff are always accessible and willing to help. Coordination and scheduling are always well thought out and communicated from planning to completion. The jobs are often local, and our employees enjoy investing in the buildings in their community.”

At D&B Construction we like to think of our trade partners as an extension of our team. We are proud to call Paramount Contracting an extension of the D&B family. Every project we have collaborated with them on results in a final product that both teams can be proud of and that our customers can look forward to.

Technology is ever-evolving, and part of this evolution includes the construction industry. In response to COVID-19 and technological advancements, the construction industry has begun to innovate more than ever before. One of the most fascinating practices that is growing in popularity is modular or off-site construction.

Modular or offsite construction is the process in which a building is constructed off-site under controlled conditions using the same materials and built to the same standards as conventionally built facilities. The only difference? It can be built in nearly half the time. Buildings are constructed in modules that can be put together to form the original design, all while still resembling the work of the most sophisticated site-built facility. Why do companies use modular construction? The answer is simple. Modular construction is greener, faster, and safer.

A Greener World with Modular Construction

Since modular construction is a factory-controlled process it generates less waste and creates a site that is less likely to evoke disturbances. A modular construction site also promotes more flexibility and re-use. Modular projects can be disassembled and relocated or refurbished for new use. This reduces the demand for materials and limits the amount of energy used to create a building that meets the new needs. Additionally, a modular site produces less material waste since the building is constructed in a factory and waste is eliminated by recycling material, controlling inventory, and protecting building materials.

Finish Projects in Record Time

Modular construction is also faster than traditional building methods. Construction of modular buildings occur while site and foundation work are both being done. The Modular Building Institute reports that this can reduce construction times by 30%-50%. This can also be credited to the elimination of weather delays. Sixty to ninety percent of construction is completed inside of a factory, leaving no need to worry about inclement weather delaying a project.

Staying Safe with Modular Construction

One of the most important benefits of modular construction is safety. As we know, safety is always a priority in construction, and modular building makes it easier than ever to be safe. A report by McGraw-Hill Construction found that over 1/3 of their respondents (34%) who are currently using modular construction have seen site safety improve. This may be credited to the fact that it is free from weather elements like rain or snow that can cause slips and falls. It also reduces the risk of a worker falling from great heights, which OSHA reports as the cause of 33.5% of construction worker fatalities. Learn more about OSHA and their dedication to safety by reading this article on D&B Construction’s blog.

Modular Construction: How It’s Done

Modular building is done mostly on the ground level, but if working from height is required permanent scaffolding is used. This permanent scaffolding is different (and safer) from the scaffolding normally used on a traditional job site. Because it is not constantly being moved and reassembled, there is less likelihood for error and accidents.

Modular construction is growing in popularity. According to Fortune Business Insights, the global modular construction market is going to be valued at $114.78 billion USD by 2028. The market was valued at $72.11 Billion USD in 2020. Here are some examples of just how much you can do with modular construction:

Star Apartments, Los Angeles, 2014

The Star Apartments in Los Angeles were built in 2014 on top of a previously existing single-story commercial building. A concrete superstructure was poured over the existing structure. Next, five stories of modules that were built off-site were added on top of the single-story commercial building. The modules were stucco-finished on site. These modules provide 102 apartments and have pre-installed bathrooms, appliances, cabinets, and surface finishes.

Habitat 67, Montreal, 1967

An iconic example of modular construction is Habitat 67. Built in 1967, architect Moshe Sadfie’s unique cuboid block of 158 apartments caught the eyes of many. The way Sadfie designed Habitat 67 allowed for 15 different kinds of housing, gardens and terraces to fill the voids in between. The complex stack of concrete houses was connected by high-tension rods, steel cables, and welding. Even though it was built in 1967, Habitat 67 shows the true possibilities of modular construction.

Nakagin Capsule Tower, Tokyo, 1972

This 14-story tower was the world’s first example of permanent modular construction. The building has 140 self-contained, prefabricated concrete capsules that each measure 2.3m x 3.8m x 2.1 m. The capsules were each connected to the shaft of the building with just four high-tension bolts, allowing each unit to be replaceable if needed. These capsules were delivered to the site already fitted out with a small bathroom. Owners used the capsules as small living or office spaces, and the interior space of each module can even be extended by connecting to other capsules.

These are three unique examples of modular construction because of their structure. While these extravagant and unique designs are made easier with modular construction, you can also make very basic structures that look identical to buildings that are constructed on-site. The possibilities with modular construction are seemingly endless thanks to its ability to make construction greener, faster, and safer. We look forward to seeing just how far modular construction will go.

Cold weather is upon us as we gear up for another Winter season. It is crucial that all workers in the industry are prepared to work in these cold weather conditions. We prepared Team D&B for the cold months ahead at the start of December during our monthly Safety Meeting. Our Superintendent, Jason, presented a Tool Box Talk on Cold Weather Considerations. Since safety is our standard we wanted to share some of the pointers our team discussed during our latest Safety Meeting:

-Wearing several layers of clothing is always more beneficial than wearing one thick layer when working in cold weather.

-Did you know that forty percent of a person’s body heat can be lost from an uncovered head?! Because of this, wearing a warm wool hat or a helmet liner under your hard hat is always a good idea. Be sure to cover your ears and remember to wear gloves, too!

-When it comes to footwear, wear one or two pairs of warm socks. Your footwear should not fit too tightly or it will restrict blood flow and ultimately cause more harm than good.

-In cold, windy weather it is a good idea to wear a face mask or scarf.

-You need energy to keep your muscles warm, making it important to avoid exhaustion and fatigue. Take frequent short breaks in a warm shelter so your body has time to warm up and relax.

-Drink warm, sweet beverages and avoid drinks with caffeine. Eat warm, high calorie food such as pasta dishes for lunch.

Tom Rinaldo, our Safety Director and Vice President of Construction for Reading and Central PA, also provided us with some helpful insight to common questions people tend to have regarding cold weather safety:

Q: What are some ways you keep warm when working outside in the cold?

A: “Proper attire during the cold weather months is a definite must. You definitely want to have proper socks and footwear. Keeping perspiration away from the skin is a big one. You want socks that wick sweat and perspiration. Wearing synthetic or cotton clothing next to your skin is the best way to wick away any sweat. If you keep that sweat away from your body, you won’t get as cold. The reason people’s feet get cold is from sweating, which happens even in the winter – especially when working on a construction site. The body can lose up to 85% of its heat through sweating during exercise. I recommend purchasing socks that wick the sweat away from your feet to help you stay a lot warmer. There are several different brands available. I believe Under Armour makes them, and Wick Dry CoolMax by Fox River is another go to brand.”

Q: What different kinds of foods do you eat/drink in the winter to keep you warmer?

A: “You always need to stay hydrated. People don’t realize this, but even though it is Winter you still need to drink plenty of water to stay hydrated. You will see me with a thermos of hot soup for lunch instead of a cold sandwich in the winter time.”

Q: Do you make sure you go somewhere warm for breaks in the colder weather? If so, where do you suggest?

A: “We usually tell the guys to go into their vehicles if they are out on an open construction site. If they are on an interior construction site there is usually heat on. At our job sites, we also have temporary heaters on. These are not only to keep the worker’s warm, but also for the product we are putting in. Once you get to drywall you have to condition the space.”

Q: What are some clothing layering methods you use?

A: “A very important factor is keeping the wind off you. When you layer your clothing your cutting the wind out from getting to your body. Having the proper gear, such as boots, gloves, and a hat are very important. Last month we got a new order of hats so our Team has them to put under their hard hat when on the job site.”

Tom usually wears three layers under his winter coat: A t-shirt, a long sleeve t-shirt, and a hoodie. He also wears long underwear, wicking Under Armour shirt, and Under Armour bottoms.

Q: What are some ways that a Site Superintendent can help the men and women on their job sites stay warm?

A: “Making sure they have the proper attire and making sure they are taking the proper number of breaks, especially when the temperatures get below 20 degrees. We typically have two 15-minute breaks throughout the day, one in the morning and another in the afternoon, in addition to a lunch break. At D&B, we always educate our team on hypothermia at safety meetings and in our safety training. We know that one of the main injuries, according to OSHA, would be slips and falls. This, along with hypothermia, frostbite, ice, cold stress, and winter colds and flus are common winter hazards that we educate the team on.”

Q: What do you recommend someone new to working in the cold weather prepares for?

A: “It is important that they make sure they have the right clothes. They may not be used to spending eight hours out on a construction site, so it is important that they have the proper gear for the elements.

Q: Are there any common misconceptions that people think are helpful in the cold, but are harmful?

A: “Coffee might warm you up for a few seconds, but since it contains caffeine it can increase your urination frequency and ultimately dehydrate you. Make sure you drink it in moderation to avoid this.”

Q: Anything else you want to add?

A: “You have to know when your body is telling you to get away from the cold environment. Realizing the signs of cold stress, hypothermia, frostbite, etc. are important. Listen to your body. It will tell you when to stop doing what you’re doing.”

Frostbite and Hypothermia: Two Serious Conditions That May Result from Prolonged Exposure to the Cold

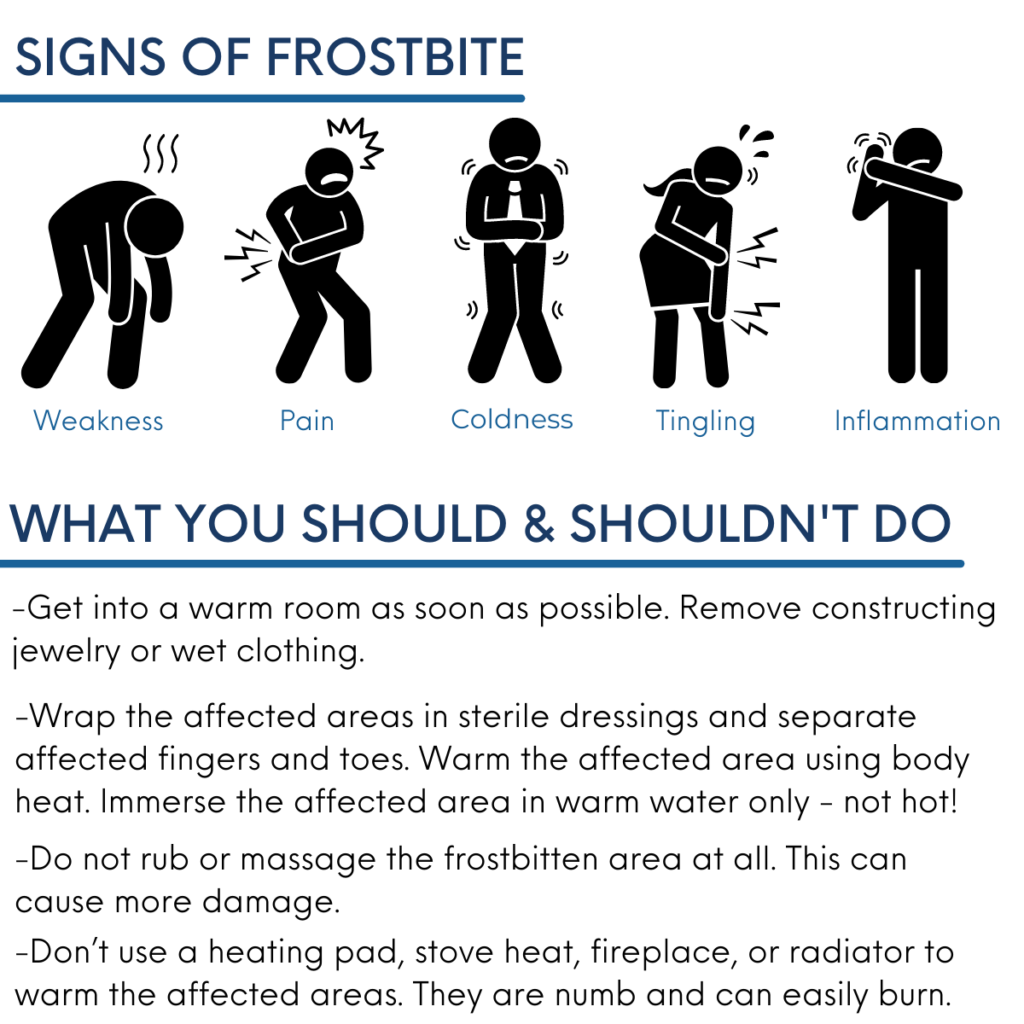

Frostbite is an injury to the skin and underlying tissue. Most often it is found on a person’s nose, ears, fingers, or toes. One of the first symptoms are a “pins and needles” sensation followed by numbness or pain in the affected extremities. Hard, pale, and cold skin is a way of distinguishing frostbite. Once the area thaws, the flesh becomes red and very painful.

Below is an infographic illustrating signs of frostbite and some pointers on what you should and shouldn’t do if you or someone on your job site is affected:

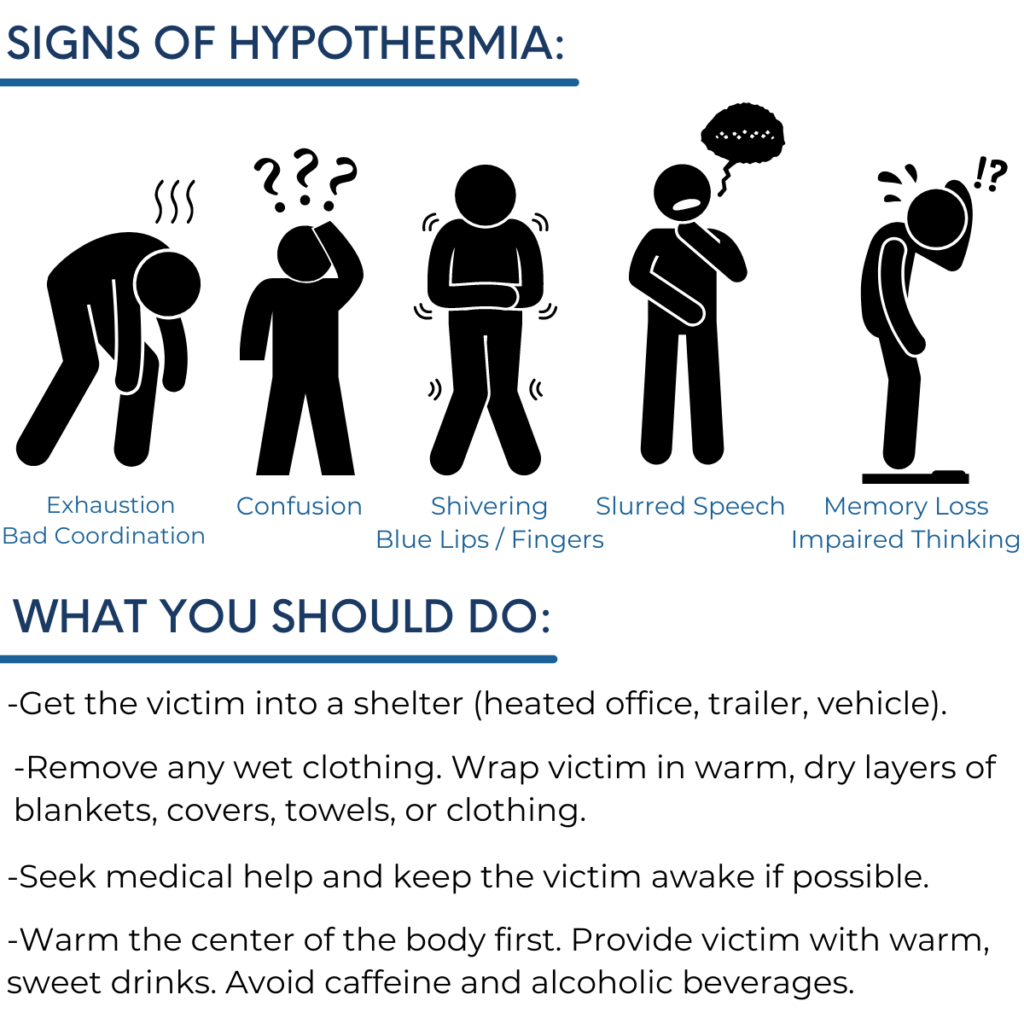

Hypothermia is a medical condition in which the person’s core body temperature drops significantly below normal and normal metabolism begins to be impaired. This occurs when the core temperature drops below 95 °F (35 °C). If body temperature falls below 90 °F (32 °C) the condition can become critical and eventually fatal. It is important to note that Hypothermia can still occur at temperatures well above freezing when a victim is submerged in cold water.

Below is an infographic illustrating signs of hypothermia and some pointers on what you should and shouldn’t do if you or someone on your job site is affected:

Consider printing out OSHA’s Cold Stress Card in both English and Spanish to have on the jobsite for all workers safety. These cards include information on common types of cold stress, such as hypothermia, frostbite, and trench foot (also known as Immersion Foot), as well as ways to prevent it and treat it.

We hope you find this article helpful as you and your team brave the cold winter months! If you have any additional tips, we’d love for you to share in the comments below.

As the world seeks ways to be more environmentally friendly, many big industries have made changes to be sustainable. Construction has joined in on these efforts, paving the way for a more sustainable future.

Our industry has the unique opportunity to significantly impact climate change for the better since a large amount of energy and material is used in the construction process. The goal for construction is to become sustainable by reducing its impact on the environment through the construction of green buildings, utilizing sustainable materials, and employing energy efficiency. How are companies in the industry achieving these goals? Let’s take a look:

Green Buildings and LEED

Green buildings are buildings that have been constructed with respect to environmental sustainability. They first came about in the 1970’s, eventually gaining more popularity in the 90’s when the first Green Building Council was formed.

The generally accepted definition for a green building is “the planning, design, construction, and operations of a building with several crucial considerations: energy use, water use, indoor environment quality, material selection, and finally how the building affects its site.” One of the most direct ways that construction is sustainable is through LEED, the most widely used green building rating system in the world. The effectiveness of a green building is coded by the LEED Green Building Rating System.

Before LEED was established in the mid to late 90’s, there were green building projects, however there was no way to know if they were being implemented effectively. Nowadays, LEED will give out plaques to buildings which have been constructed to be sustainable. There are more than 60,000 buildings that participate in LEED today, occupying up to 1.7 million square feet.

Individuals throughout the industry can also earn a certification from LEED, which is exactly what one of our team members has done. D&B Construction’s Operations Manager, Jessica Nelis, obtained her LEED AP, ID+C (focused on interior design and construction) certification around 2010. Jess says, “I became a LEED accredited professional because I knew it would be important and relevant moving forward.” Jess provides a unique perspective on environmental consciousness that we take seriously here at D&B Construction.

Not only are green buildings environmentally friendly, it has been discovered that green buildings promote healthier living. Research shows that people who live or work in a green building experience proven psychological benefits. For example, in a green office building cognitive function scores rose by 61 percent. It is also reported that employees were 44 percent better at making decisions towards achieving workplace goals. In addition, at the Akron Children’s Hospital, 56 percent of people were satisfied with the cheerfulness of the hospital after its own green building renovations. There were also decreased reports of Seasonal Affective Disorder.

According to a report conducted by Grand View Research, the green building materials market has been a vital part of the construction industry’s green footprint, like Jess thought, and is expected to be worth $364.6 billion by 2022 (compared to an estimated $238 billion in 2020).

It’s clear to see why demand for the use of green materials has been a recent trend in the construction industry. Because of this demand, innovative green materials have become very popular.

Trending Sustainable Materials

Sustainable construction is achieved through using sustainable materials such as bamboo, eco-friendly insulation, and even smart glass windows.

If you want to be more sustainable, you could consider bamboo flooring for your project. Bamboo is a great alternative because it looks like wood but has a harvesting cycle of only three years, 22 years shorter than that of a tree. If you choose to use bamboo, you are helping to slow the rate of deforestation by allowing time for trees to grow back.

If insulation adequately cuts down on the energy used for heating and cooling, it could be sustainable. However, this can be counteracted if batts, fillers, and sprays that are not sustainable are used on the insulation. What is the eco-friendly option gaining popularity lately? Hemp insulation. It has all the same properties of normal insulation, but it is a sustainable option. Because it can be compressed, hemp can even provide more superior insulation than your typical insulation.

Another recent movement in sustainable construction is the use of smart glass windows. They were invented in the early 2000’s but have only recently become a building trend. Smart glass changes its heating properties based on the temperature outside, affecting how the heat and air conditioning is run through the building. During the hot summer months, a smart glass window will become translucent to block heating wavelengths that would allow you to run the air conditioning less and vice versa.

There are several options available if you wish to replace your windows with smart glass windows. These options vary in pricing and components of their smart glass technology. First, there are dynamic smart windows, produced by View Smart Windows. This is the “luxury” option, costing $50 to $100 per square foot, in comparison to a normal window which costs $10 to $15 per square foot. This high-end option replaces your normal windows and is even equipped with Wi-Fi control through their downloadable app.

A more cost-effective option is Invisishade’s self-adhesive and smart glass windows. Invisishade offers a “plug-and-play” adhesive film kit which transforms your normal window into smart glass. A sample of their self-adhesive film kit would cost $99, or $249 for a pack of three. The final price of their product varies on size and scope of the project, however Invisishade would offer a discount on bulk .

Smart Glass Windows may seem as if they are an expensive solution for sustainability due to its pricing when compared to normal glass windows. However, manufacturers claim that you can save up to 20% on your monthly energy costs because of their tinting properties. Smart glass allows you to save money on your monthly bills while also making the property look more aesthetically pleasing by eliminating the need for blinds.

Upcoming Trends: Self-mending Concrete

Be on the lookout for an emergence of living materials being used to complete green building projects in 2022. Living materials are biological compounds that grow and are ready to produce full-scale production. An example of a promising living material we have not seen much of yet is self-mending concrete. This concrete is full of bacteria that bind the materials around them into a new material form. This material can grow itself into the pores of concrete, essentially being able to rebuild the concrete on its own. The bacteria inside of this concrete can live for up to 200 years. Scientists say that in theory the bacteria would then be able to extend the concrete’s life for that long as well. Seeing as normal concrete lives for 50 to 70 years, this self-sustaining concrete would be much more useful in the long run. We have only begun to scrape the surface of possibilities for this self-mending concrete, but as we learn more it may prove to be a revolutionary material in construction.

New forms of concrete are a key component to sustainability since it is the second most used material on Earth, with only water exceeding it. One of the trends that will become increasingly popular is 3D printing with concrete. This year a 3D printed home community was constructed in Austin, Texas by ICON. It consisted of four homes, all listed on the market for $450,000. The company that built the houses used 3D printing technology to create the first floor of all four homes while the rest of the homes were built conventionally. Houses of this size can be constructed in just five to seven days. The homes were built using cement-based material LavaCrete, a material designed to cope with extreme weather. LavaCrete lived up to its claim when the houses withstood a 7.4 magnitude earthquake with no damages.

The Austin homes are not a unique case. There is also a 3D printed home community being built in Coachella, California. By 2022, this community is going to have 15 houses, each of which will be 1,450 square feet and feature three bedrooms, two bathrooms, a terrace, and a swimming pool. Sustainable real estate development group Palari and construction technology company Mighty Buildings will work together to complete the project.

The potential this unique industry has does not stop at high-end homes… nor does it stop on this planet. ICON, the same company that built the Austin, Texas community of 3D printed homes, is currently working in the research and development phase with NASA to create a space-based construction system. Their goal is to construct 3D printed buildings on the Moon and Mars.

The industry has already evolved as people are beginning to purchase and live in 3D printed homes. Meet a previously homeless Texas man who became one of America’s first inhabitants of a 3D printed home. The best thing about 3D printed concrete for homes is that it is environmentally friendly. This form of building uses the exact amount of material needed to complete the project, allowing for less materials like concrete to be used to construct the building, therefore benefitting the environment.

The potential that 3D printing concrete has is immense and is something worth following as they make progress over the next few years. Stay up to date with 3D printing news here.

Concrete is the second most used material on Earth, trailing only water. Because of this and our commitment to safety, we find it important to highlight concrete safety tips. Here are some vital practices that every company should follow to stay safe when working with concrete:

Use Proper PPE To Protect Yourself

PPE is one of the most important elements of safety on any jobsite, but it is especially important when you are working with concrete. Make sure to protect your skin at all times by wearing gloves. Water-proof and alkali-resistant gloves are recommended. A long-sleeved shirt, full-length pants, and shatterproof eye protection are also important when working with wet concrete. If you are standing in the wet concrete, wear water-proof boots that are up high enough on your ankle so that the concrete cannot flow into your shoes. You will also want to always wear a hard hat, especially when pouring concrete in an interior area where the ceiling is not yet complete. Proper ear protection, proper footwear, and face masks or ventilators are also important PPE.

Take Care When Removing Concrete PPE

Be careful when removing concrete PPE, as wet cement could get on your skin. Did you know that wet cement is the #1 cause of occupational skin disease in the United States? To learn more, watch this video, which includes additional concrete safety tips. Concrete burns are a serious and common injury when working with concrete. It is important to always be aware that concrete can find its way into your personal equipment such as gloves, boots and sleeves. To avoid getting burned, remove any clothing splattered in concrete and wash the affected area immediately, not in the next hour. You will then want to keep an eye on your skin to see if a burn is developing. Be careful when you are removing your protective clothing and wash your hands before and after. You should also store your concrete-soiled clothes separately from other clothes and tools. If possible, shower before leaving the jobsite so you can change into new clothes. This will decrease your exposure to crystalline silica, which we discuss more in depth below:

The Dangers of Crystalline Silica

Crystalline silica are very small particles, nearly 100 times smaller than the sand we find on beaches. These particles are present in concrete and other building materials. Even with proper safety precautions, workers who are exposed to crystalline silica may still inhale the dangerous particles.

To be safe, warn workers and mark boundaries of work areas with crystalline silica. It is a best practice to do this because when large amounts of crystalline silica are inhaled, workers are at risk of developing a long-term lung disease known as silicosis. Silicosis can be fatal. The CDC reports that 1,167 people died from silicosis from 2005-2014. Make sure to educate your workers about the risks and harm of crystalline silica by providing proper training that includes information about health effects, work practices, and protective equipment for respirable crystalline silica. You can also learn more about the standards OSHA requires here.

In addition to educating and training your workers about crystalline silica, you should also provide those exposed to crystalline silica with periodic medical examination. One of the best ways to prevent the inhalation of crystalline silica is to keep dust out of the air. When you are purchasing equipment look to see if there is a dust control, make sure to always maintain and use the dust control system, and if the dust control system is not working do not use the equipment. Using the nearby exhaust ventilation system can help to keep dust from being released into the air. When you are sawing concrete, you can use a saw that provides water to the blade, as this will make the dust particles wet and prevent it from being released into the air.

To learn more about preventing the inhalation of crystalline silica watch this video.

Some Items Should Be Avoided When Working With Concrete

When working with concrete, steer clear of using tobacco products in dusty areas. BioMed Central did a report in 2018 that found silica-exposed smokers had elevated mortality from non-malignant respiratory disease and lung cancers in comparison to non-smokers. The use of tobacco in dusty areas may leave you more likely to inhale crystalline silica. To proactively prevent the inhalation of crystalline silica you should do air monitoring to measure worker’s exposure to crystalline silica, as well as to select appropriate engineering controls and respiratory protection. You should perform air monitoring to measure the effectiveness of controls, collecting and analyzing air samples according to the National Institute for Occupational Safety and Health Method Nos. 7500 and 7602.

For this quarter’s trade partner spotlight, we are taking a visit to Fleetwood, PA, where AP Merkel Inc. has resided since the 1890’s. AP Merkel is a four-generation company that offers plumbing, heating, and cooling services. They have come a long way since Augustus P. Merkel first founded the company over 100 years ago. AP Merkel first started out as a company that built farm implements, such as machines that would harvest crops. They are well known for manufacturing grain separators known as threshing machines.

Their transition into the HVAC world all comes down to a smart, strategic business move. “Eventually, all of these farms that AP Merkel was working with needed heat,” explains Nate Lobb, an Estimator who has been with the company for 10 years. One thing led to another, and eventually the company added plumbing into their wheelhouse. Approximately 30 employees later, “the rest is history,” sums up Nate.

Today the company is run by Pete Merkel, standing President, and busy with approximately 50 commercial jobs a year. Nate is usually efficiently juggling 20 or so jobs at a time, which he enjoys. “I like the diversity of projects we work on. We do everything from senior living, to coffee shops, to dentist offices,” he explains. Nate also enjoys working through and overcoming the challenges that come with starting every new project. “Being involved in a job from when it is just a concept in budgeting to when it is complete is something I always enjoy,” he says.

Nate, who received his plumbing license about five years ago, grew up in a construction environment. “My dad was always in construction. I had an interest more in the mechanical / HVAC and plumbing side of things,” he explains. Nate earned his Environmental Studies degree from Temple University in Philadelphia, PA. While in college, he interned for a company in Philly doing HVAC work and ended up coming back to the Fleetwood area and continuing his career at AP Merkel.

Nate stresses the fact that now is a great time to get involved in the industry. “There is a HUGE need for young, licensed tradespeople. There are few young people getting into this field right now. Get your license when you can, take it seriously, communicate, and you can have a great career,” he urges.

One young individual who has impressed Nate is D&B’s Superintendent, Ryan Hummel, who he has worked with since D&B Construction and AP Merkel established a relationship within the past year. “He has been really helpful and knows the industry, especially for being a younger guy. Ryan is really on top of it and not afraid to pick up the phone and check on something with us. We can talk through things and work it out. It is clear he takes his job serious,” explains Nate.

This feeling of open lines of excellent communication is just as strong a value for AP Merkel as it is for Team D&B. When we asked Ryan what he likes about working with AP Merkel, he summed it up simply in one word: “Everything.” However, what stands out most to Ryan is “their level of communication and coordination from their office staff to the field staff.” His experience working with AP Merkel over the last year has shown him that “they run a tight ship.”

An example of this can be found at one of our healthcare projects currently in active construction, Grove Dental Pediatrics. Ryan has worked with Nate and Tom, AP Merkel’s Superintendent who has been with the company for around 25 years. “I bid the Grove job, completed estimating, submittals, and the purchasing of equipment and piping, and Tom took it from there and is currently managing the actual job,” explains Nate.

One highlight of this 3,700 SF medical office space? “This project has medical gas piping, which is something we don’t deal with that often. This type of piping has to be put in very clean. It has a special fitting with a braised fitting joint. The key is to keep it clean, so when we start to install it we have to flush it with nitrogen gas,” explains Nate.

We recently visited this healthcare project in Wyomissing, PA. Here’s some photos of AP Merkel team members, Andy, Zach, and Scott, their lead plumber, working to keep the job running smoothly and safely with Team D&B:

Our first Trade Partner Spotlight features Gillespie Electric, Inc. Located in East Greenville, PA this full-service electrical contracting company has been a recognized industry leader known for its reliability for over 40 years.

We recently drove out to Souderton, PA to check out the new 12,500 SF community health center quickly taking shape for the Children’s Hospital of Philadelphia. Every time we visit we are greeted by the smile of D&B’s Superintendent on the jobsite, John. He always has a positive energy about him, but when we visited on June 23rd he was literally excited to show us the work that Gillespie Electric, Inc. just completed. We’ll show you as well so you can see what John was talking about:

Although new to Team D&B, John has been in the industry working on a variety of large construction projects over the last 34 years (including the delicious Steak 48 on Broad Street in Philadelphia). John described the work the Gillespie team completed as a “quality standardized performance” and claimed he has never seen such well-executed work from electricians. “This demonstrates the quality and care that these guys have to make this job beautiful,” says John with a smile as he admires their work once more.

According to Gillespie Electric’s Project Manager, Keith Lewis, who has worked on this healthcare project with D&B Construction since it began, they “have been on and off site since this project first broke ground last year and will be on site until the job is complete in a few months.” Over 350 receptacles and 15,000 linear feet of HFC Hospital grade MC are being installed on this project. “All of the lights are LED and we are installing a back-up generator for all of the vaccine refrigerators,” explains Keith.

The company’s Foreman, Mike, as well as Nick (who John admiringly refers to as “another badass” on the Gillespie team) just recently finished tying everything into the panels, a job that took about a week to complete. “Mike and Nick both completed two different rooms. A lot of times when you have two electricians on the same job you can notice slight differences, but their work looked identical. I couldn’t even tell who did which room since their work was so precise,” says John.

The Foreman, Mike, has been with Gillespie for 10 years since 2011 and received his Electrical Apprenticeship from Bucks County Tech in 2012. Keith, who sings high praises of his co-worker, says that Mike was a journeyman for nine years and became a Foreman at the company last year. “Interestingly enough, this job is Mike’s first job that he is completing from start to finish as a Foreman. It’s not every day you win both the core and shell and fit-out phases and are able to be involved in the entire project.”

Although Gillespie has completed a number of jobs for CHOP over the years, this is the first job they are completing for D&B. “There are always some challenges when working with a new general contractor,” says Keith. “It’s like when you first start a new job. You have to feel out your new boss, and they are doing the same with you. But we have had very minimal challenges working with D&B. Communication has been easy, and working with Jim (D&B Project Manager on the job) has been easy, too. It honestly feels like we have been working with them for much longer than we have.”

Keith had similar remarks to say about our Superintendent on the job. “John is on top of things. He gets questions answered efficiently and makes good, on-his-feet decisions. If I ask John a question, I know I will have the answer within a day or two. That’s unusual. Construction should be fluid, and he makes it that way,” says Keith.

At D&B, we view our trade partners as an extension of our team. That’s why we work with trusted trade partners like Gillespie Electric who bring the same level of care that we do to the jobsite.

If you are even remotely connected to the construction world, talking to you Mr. and Mrs. weekend DIY’er, you have heard about the current state of construction material costs. Last week lumber hit a new all time high of $1,188 per thousand board feet, nearly a 250% increase from the same time last year. The worst part? Prices are expected to climb further through the remainder of the building season. Steel products, if you can find them, have also doubled in pricing over the last six months. This perfect storm of sky-rocketing costs has forced contractors, developers, business and home owners, suppliers and everyone else in the supply chain to adjust. Some are hoarding materials while others just hit the pause button. Ground-up construction for the remainder of 2021 looks to be a big question mark for everyone. However, one sector is proceeding full steam ahead; adaptive reuse.

Adaptive reuse, historically, has been seen as an eco-friendly construction practice that “recycles” existing structures through a conversion of it’s intended use into something new. In Baltimore, the old Pratt Street Power Plant was converted into retail and restaurants. In Philadelphia the Independence Press Building, a paper box production facility, is now a 92-unit apartment building. You can find incredible examples throughout the world of converted buildings getting new life through reincarnation. Given the current construction climate due to soaring costs, the green tint of adaptive reuse isn’t coming from the ingrained environmental benefits. It’s coming from money.

Developers who have long valued the environmental impact of reusing or repurposing a building are finding new returns on their investments. The financial benefits speak for themselves. Cost savings are everywhere in adaptive reuse. Obviously, it takes a lot less material reusing an existing structure than building a new one out of the ground. Beyond that, savings are coming in the way of demolition costs, design and approvals, and time, which is commonly overlooked. Other non-monetary benefits include preserving a community identity, enhancing local accommodations and offerings, economic and environmental sustainability, among others. It is no surprise why adaptive reuse is getting so much attention.

Fortunately for D&B Construction Group, there are a few of these projects in pre-construction and under construction currently. The Metropolitan Edison Building, once the tallest building in Reading, Pennsylvania, is a prime example of adaptive reuse. This 14-story brick building is being converted into market rate apartments to answer growing demand for modern urban multi-family living. A stone’s throw up Washington street is another adaptive reuse project that will start this summer. The Berkshire Building, originally a hotel then converted into office space, prepares for new life as student housing supporting Alvernia University’s new Collegetowne campus. The projects have been a boon for D&B. Dan Gring, D&B Construction Group CEO, recently reflected on the downtown Reading, PA projects:

“To have these large projects that are filling a need in the community, creating a good business venture for our clients, and providing the company with steady and reliable work is invaluable. There’s a lot of speculation and analysis between us, our clients, vendors, and so on with new construction projects that has many people in our industry worried. Luckily for us, we’ve built a wide range of clients who trust us with their projects, and we’re fortunate that several of them focus on adaptive reuse projects. We know with relative certainty that material costs are not jeopardizing those jobs.”

Environmentally sustainable, financially conscious, and preserving communities. It’s a winning solution all the way around in the current construction market. Whether or not adaptive reuse projects see a spike as a result of the pandemic fallout or not remains to be seen. In the short-term companies like D&B and our clients will continue to reap the benefits of this construction approach.

— Drew Bell, VP of Business Development

Drew Bell, of Wyomissing, brings over 10 years of marketing and business development experience to D&B Construction Group. Prior to joining the team in March of 2020, Drew served as the Business Development Officer at Tompkins VIST Bank. He was also the President of the Reading Royals professional hockey team for three years. Drew is a strong believer that “genuine opportunities come from trust based on knowledge and sincerity.” His dedication to creating and strengthening mutually beneficial partnerships to make collective solutions and his contagious, positive attitude make him not only a huge asset to our team, but a well-respected individual throughout the communities we serve.

Drew graduated from Penn State University with a Bachelor’s Degree and received his J.D. from Widener Law School. Active in the community, he is a member of the Berks and Pennsylvania Bar Associations and a committee member for Berks Catholic High School. He previously held board positions with the Greater Reading Convention and Visitors Bureau, as well as the Gilmore Henne Community Fund, Boy Scouts of America Hawk Mountain Council, and Salvation Army of Reading.

Born and raised in Wayne, PA, a suburb of Philadelphia, Drew relocated to Reading in 2010 with his wife, Maryanne Post, after the two graduated Law School. Drew and Maryanne live in Wyomissing with their three kids Charlotte, Amelia and Scotty. In his free time Drew loves to golf and be outdoors.

It’s hard to believe it has already been one year since we completed renovations that converted two existing administrative office spaces into a state-of-the-art orthodontic office! Aside from this healthcare project’s stunning design, this project was special to us because it was the start of Wyomissing native and local orthodontist Molly Hottenstein’s dream of owning her own practice. Molly knew she wanted to be an orthodontist since high school. It was then that she shadowed various doctors because she always knew she wanted to work with people in the medical field. She shadowed an orthodontist and immediately knew it was for her. “I loved the science behind making smiles beautiful… The perfect balance of physics and biology and art. I also loved being able to hang out with cool kids, teenagers and parents all day while really getting to form relationships with them over the course of their treatment. I loved that I could be part of an amazing community and hopefully make a difference in some of their lives,” explains Molly.

Now, she didn’t always plan on opening her own office. That wasn’t on the horizon until after she had worked four years as an associate at different offices. “It was then that I realized I wanted to bring something different to Berks County,” she recalls. She dreamed of opening an office that offered patients something more personal and a bit slower paced, allowing for more one-on-one time. In doing this, her patients would become her friends and family, not just another case. “I wanted to bring a little ‘Disney magic’ to my office, making it a place people wanted to come. I wanted them to feel like there was something different about what we were offering, and the only way to do that was to take the plunge and create it.” And take the plunge she did! It was the D&B team’s pleasure to be able to watch Molly’s hard work turn into a reality before her eyes through the construction of her one of a kind office!

Today, Molly Hottenstein Orthodontics is still loving their office as much as (if not more than) the day they first laid eyes on it. We’ve loved watching them grow since first opening their doors on March 10 of last year, and we are so happy to see them celebrating one year in their office space. Of course, it doesn’t take a math whiz to figure out that the date Molly’s business opened unfortunately coincided with state-wide shutdowns due to the spread of COVID-19. They actually had to shut down operations just two business days after their grand opening… Definitely not something that Molly was anticipating! In reality Molly and her team were planning two grand openings, one for the dental community and an open house for the entire community as a whole.

Like many local business owners, a lot of perseverance and adaptability from her team had to take place within the last year. We sat down with Molly to reflect on the rollercoaster of emotions that she and her team went through after having to shift gears from “grand opening of their beautiful office space” to “closing down operations due to a global pandemic” in a matter of just 48 hours. Here’s what she had to say:

“It was heartbreaking and terrifying. I was six months pregnant and would walk around my empty, beautiful office and cry because I just wanted people to be able to use and enjoy it,” recalls Molly. However, she didn’t let herself wallow in her pity for long. “After a few weeks of crying, I pulled myself out of the pit” she says with a laugh. “Fortunately, the office is laid out in a way that I can easily keep families separated and manage the flow in and out.”

Molly and her team continue to “learn, adapt and grow,” just as any start-up would – pandemic or no pandemic. “Honestly, I don’t have experience with any other start-up NOT during a pandemic,” she says. Molly applauds her staff, who have been “incredible at adapting, learning and being flexible.” The team of three has also received amazing support from the community and other dentists throughout the area. With a smile on her face, Molly says: “At this point, I feel like we are thriving despite the difficult timing!”

Transforming an Office Space to an Orthodontics Space

What all went into transforming Molly Hottenstein Orthodontics’ office space into the area the community knows and loves today? The team at D&B actually renovated two separate spaces and connected them into one larger space. Molly recalls the spaces being “pretty much bare bones” when she first saw them. Even still, she fell in love with a few key elements that our crew kept and highlighted in her new office space. Molly knew she wanted to have a lot of natural light to help keep her office cheerful and bright. “I love spending time outside, and I wanted my staff to not feel like they were stuck in an office all day,” she explains. Luckily, the space already had large windows around the exterior walls, and it was a no-brainer that they were here to stay. Another added bonus to these windows? Molly didn’t have to worry about decorating bare walls! “I love that nature is my best decoration. The property management group does an amazing job keeping the area landscaped and clean, too,” she says.

When it came to creating the vision for her office, Molly’s husband, Kyle, was by her side! “We always had a very focused vision for the look and feel we wanted for the office,” she recalls. “My husband and I are the perfect team because we have very similar taste. I have a very specific vision for the big picture and feel, while he is very particular and good at digging in to the details and making everything perfect.”

It also helped that this wasn’t their first rodeo. The couple worked together to decorate their home, and Molly’s husband even completed their home renovations. “We really wanted to have a professional space that looked and felt more residential. We met with three potential contractors and D&B was the first that completely embraced and understood that!”

Molly and Kyle took care of the design and selection, while the D&B team gave this dynamic duo direction so it was easy for them to find exactly what they were envisioning. Molly recalls spending A LOT of time on Pinterest and Houzz looking at architectural and design aspects so they could gain an understanding of what they loved and wanted to incorporate into the space. Kyle even made an extensive PowerPoint showing all of the images and aspects they loved to illustrate where they wanted to utilize them. From there, D&B helped make the vision possible.

From Rendering to Reality

One of Molly’s favorite parts of the construction process was meeting with the subcontractors and seeing how all of the little pieces fit together to start making her vision come to life. Molly’s husband, Kyle, enjoyed seeing the progress made every single day and how each small step got them a little closer to the beautiful finish!

“Honestly, Kyle was the most involved with the entire process. He is amazing! This wouldn’t have happened without his hard work and dedication, and I am forever grateful for that,” Molly says. “Kyle was very hands-on throughout the entire process, and D&B was amazing at staying on schedule and keeping us informed.”

Molly and Kyle had known of D&B through friends. “We knew they had done amazing work with different offices, and honestly, we had the most amazing experience with D&B. I can’t imagine having it go any better. The amount of detail and communication they had with us was unmatched. I was so impressed with how thorough they were and how well they kept us in the loop and on schedule. My husband and I already talk about how we will use their residential services for our home project when that time comes. In fact, my co-resident even used D&B’s Philadelphia office to renovate his office after our experience,” says Molly.

Once construction was complete after just five months, Molly was moved in and all ready to go in less than a week! She was in disbelief when she first saw her new office space. “I felt like ‘WOW! No way is this mine. It’s here. It’s done. It’s better than I could have imagined,’” recalls Molly.

A Little Grit Goes A Long Way

After nine weeks of being closed, Molly and her team were able to open up their office and enjoy the new space! Although they weren’t able to have the two grand openings they had been planning and many things they originally envisioned did not look exactly the same due to safety precautions, they were thrilled to be starting this chapter in their new office.

“The team has really grown into the space and gotten into a groove with our patients,” says Molly, who has two favorite spaces throughout the office. She loves her doctor’s perch because it allows her to be totally present with all of her patients, while also being available to her staff and still able to get work done. Another favorite spot is the consult room, which is the first space that families see. “I am absolutely obsessed with the windows,” exclaims Molly. They remind her of her time in college at Villanova. It was here that she fell in love with the beautiful side sun rooms that all of the older Main Line homes had. “I’ve wanted that look so bad since then, and we made that happen in the office. People LOVE it!”

With confidence Molly reports that “within the first five minutes of arriving, 99% of patients will comment on how much they love the office. They love how inviting, clean and homey it feels. People even take pictures for inspiration for their own projects!” Molly’s patients love the farmhouse sinks at the toothbrush station, and parents tend to love the bench at the foot of the clinic chairs because it allows them to enjoy the view outside the window. “We also always get comments on the colors and the counters… Everyone just says it has a good feel.”

Katelyn, Head Orthodontic Assistant, and Lyn, Patient Coordinator, appreciate the hominess of the office, just as the patients do. They describe the office as their “home away from home,” both feeling so comfortable at the office that they almost feel like they are at home and not at work. The beautiful space definitely makes it easier for them to not dread coming to work!

Aside from the overall aesthetic and design of this office space, another aspect that makes it so enjoyable to visit and work at is the atmosphere. Molly’s motto is “Personal. Passionate. Precise,” and a quick visit to her Facebook or Instagram will show you that her office is big on bringing fun and friendliness back to orthodontics.

“I think the number one key to anything in life is being genuine,” says Molly. “You can’t force yourself to be something you aren’t. To be happy and successful, I knew my office had to be a genuine reflection of who I am. I love to joke and have fun, while also being honest and a good communicator. I don’t ‘try’ to make my office fun… it just happens. My staff members are naturally this way, too. They are naturally kind and focused, and they smile and laugh. I want them to be themselves. The rest just follows,” she explains. Molly prefers this natural, organic approach over getting hung up on what her competitors are doing or feeling. “I want people to choose our office because they feel comfortable here. Orthodontics isn’t a once and done thing. It’s a relationship over a series of a few years,” she says. For that reason, she wants people to feel like her practice is the right fit for them. She doesn’t want people to come to her because she has contests, prizes, or toys. She wants them to come to her because they trust her and feel comfortable.

“I think people are starting to talk about their experience with us, and we are starting to be a little more known in the area. I hope this is just the start to the forward momentum. I am so thrilled with the outcome and so proud. I feel like the space is a true reflection of who I am and the type of service I am offering,” says Molly, with a lovely smile – of course.