D&B Construction’s partnership with Earth Engineering Incorporated dates back eight years to 2014. They have completed over 12 projects with D&B Construction since becoming our Trade Partner. These projects range from large multi-family projects on 50 acres of land to large healthcare projects for clients like Tower Health and Children’s Hospital of Philadelphia.

EEI performed numerous services on these projects including compaction testing, concrete testing, geotechnical consulting, sinkhole remediation, structural steel inspection, geotechnical investigations, clean fill assessment, and design services. Paul J. Creneti, P.G., Director of the Lehigh Valley division of Earth Engineering Incorporated, has been part of the industry for 26 years now. “Working on these projects with D&B Construction was fulfilling, as they were a collaborative effort with the construction and design team,” he reflects.

Paul has worked with many members of Team D&B over the years, including our Chief Operating Officer Brennan Reichenbach, Vice President of Pre-Construction Mark Keever, Project Manager Scott Weaver, and Vice President of Construction for Reading and Central PA, Tom Rinaldo. His favorite part of working on a D&B project? “Being part of a project team that has trust with all parties involved.” Paul can count on the fact that “quality would never be an issue” whenever he works with Team D&B. “If problems arose during development, the team handled these problems quickly and most appropriately to ensure that sites were being developed properly.”

According to our VP of Construction Tom Rinaldo, who has worked with Paul and EEI for the last 15 years on various projects, “they bring undeniable value and knowledge to D&B projects as a valued Trade Partner.” Tom most enjoys how knowledgeable their geologists are. “We utilize them to do proctors for us. They help out in a variety of ways, from testing and analysis of soil on job sites to concrete testing. When we completed work for 999 Berkshire Blvd. we had to excavate and remove 10,000 SF of soil and excavated around the entire exterior of the building to remediate soils. Their team’s analysis of the unsuitable soil and assistance in finding suitable soil was imperative to the success of this project.”

About Earth Engineering Incorporated:

This full service geotechnical / environmental engineering consulting firm was founded in 1990 in Blue Bell, Pennsylvania. By 2003, EEI outgrew this facility and established their Corporate Headquarters in East Norriton, Pennsylvania. Today they have approximately 125 employees and other regional offices in West Berlin, New Jersey, the Lehigh Valley and Central Pennsylvania that allow them to service projects from New York to Maryland.

EEI provides their clients with geotechnical engineering and environmental consulting services. Such services allow them to contribute to the successful development of a wide variety of projects for their clients, as issues such as cost-effectiveness and site development issues are evaluated by their team. This analysis allows EEI to provide clients with the best recommendations on how to proceed with their project.

The predominance of their geotechnical and environmental work is in the private commercial and residential sectors, with a portion of their geo-structural design work in the public sector. EEI takes on approximately 1,200 new projects within a year.

Q&A With Paul Creneti, Director of EEI’s Lehigh Valley Division:

Q: What’s the best piece of advice you would give to others looking to get into the industry?

A: “Listen to your client’s needs while at the same time keeping the project within or below budget. You can accomplish this through quality engineering and quick decisions.”

Q: What makes a good leader?

A: “Being true to your corporate values and goals and holding a high standard for others to follow.”

Q: What do you love most about your job and why?

A: “Being part of a project team that leads to the successful completion of projects despite countless variables along the way. It’s rewarding.”

Q: What about a D&B project stands out in comparison to other General Contractors you work with on other job sites?

A: “Quality with a strong focus on the client’s needs.”

A Look at Some of the Jobs EEI and D&B Have Successfully Worked on Together Over the Years:

Projects Currently Under Construction:

The Reserve at Iroquois Springs

EEI’s Geotechnical Engineer, Dan, was just on site last week to check the compaction rating of the soil on this jobsite. View some recent drone footage here.

Completed Projects:

Cardiology Consultants of Philadelphia – Paoli, PA Location

Bucks County Orthopedic Specialists – Warrington, PA Location

Tower Health Medical Group Family Medicine – Womelsdorf, PA Location

Riverfront Federal Credit Union

Q: What do most of your days look like on the job-site?

A: “I spend most of my days shadowing and working closely with the commercial Site Superintendent, Barry, at Stratix’s job site, as well as shadowing John, the residential Superintendent.”

Q: Tell us about a day / task that you enjoyed most at your internship so far and why?

A: “I enjoy looking over project submittals the most because I get to see how different applications on the job were approved.”

Q: What are some things you’ve learned throughout your internship so far?

A: “I learned the importance of safety on a job-site is by far the most important aspect. OSHA safety requirements are the guidelines for construction job-sites. I’ve also learned that everything must get approved before even starting and this can hold projects up for months. I’m learning about what is on the drawings and how to interpret what is on them. I also have been sitting in meetings and participating in weekly site inspections to really get a grasp of things.”

Q: What is one thing you’ve learned about yourself so far through your internship experience?

A: “That I know more about the construction industry than I thought I did.”

Q: What would you say is the most important skill you developed / strengthened at your internship so far?

A: “I learned the importance of listening.”

Q: What are your internship goals for the rest of your time with D&B?

A: “To continue to be able to complete individual tasks and be trusted at completing these tasks.”

Q: What were your responsibilities throughout this internship?

A: “My responsibilities included researching, writing, and editing articles for blog posts and newsletters. I learned about graphic design and how to create things in design programs like Canva and Adobe. I also learned how to navigate WordPress and the back end of a website, as well as MailChimp. I completed Benchmarking analysis and learned the differences between preparing copy for social media and blogs/newsletters.”

Q: Of all your responsibilities, which did you enjoy most and why?

A: “I enjoyed creating things for D&B on Canva. It gave me a chance to be creative and really understand branding. Besides that I also really liked coming up with research for articles and gathering information in general. I liked interviewing people and getting quotes and information. Interviewing people was a great way for me to learn more about some of the staff here at D&B.”

Q: How was your overall experience interning with D&B Construction?

A: “I was lucky to come into a business that was not only friendly and accepting, but that also had knowledgeable people who I could learn a great deal from, especially since this was my first internship experience. I rate my experience 10 out of 10 because coming into this, I had no idea what my internship was going to be like, but being here for a semester allowed me to learn more than I ever expected to about what goes on in a business. I also strongly believe that I gained a lot of hands on experience, from having my own computer and my own documents to work on in the office, to being able to go out to the job sites and take photos.”

Q: Do you feel this internship enabled you to apply knowledge and skills to prepare for college?

A: “Yes! Since I am in high school, I don’t have a focused major just yet, but my internship coordinator, Angela, went through a list of different tasks at the start of my internship. I was able to voice my opinion on what I thought I would be good at, what interested me, and what I wanted to learn more about. This allowed me to use my skills to the best of my ability throughout the internship. For example, I took Honors English all four years of high school, so I was able to write a lot of blogs and articles during this internship. I was given support and encouragement throughout training during my internship. If I didn’t know something, that was alright because then I was taught it, and that allowed me to learn new things and gain new skills. I really feel that this internship confirmed that I am on the right path. Through this internship experience I even realized that I would like to do some sort of marketing in my future career.”

Q: Do you feel this internship helped prepare you for your future career?

A: “Going into my internship I knew I wanted a business career, but I wasn’t completely sure what I wanted to do in the business world. This internship helped me gain knowledge about the business world and what really goes into marketing. It not only gave me an idea of what I want to go for in college, but I also gained experience and have a leg up compared to to my peers since I have an internship on my resume already. Not a lot of high school kids get this experience. This experience is valuable because it not only looks great for future jobs but will help me with getting into college.”

Q: What did you learn throughout your internship that you did not expect would be so important?

A: “I learned many things at my internship, but one thing that I didn’t think would be that important is branding and how we have the same colors and logos for everything. Another important thing I learned is the importance of having your business being a thought leader in the industry, not just as a company that does construction. I learned so many workforce skills that a classroom can’t teach me.”

Q: What are you most proud of from the work you produced throughout your internship and why?

A: “I am most proud of the blogs I wrote and posted with the help of my internship coordinator. It is something that I can say I worked on from start to finish and can add to my portfolio.”

Q: How would you describe D&B Construction’s company culture in three words?

A: “Innovative, thought-leaders, and welcoming.”

Paramount Contracting, Inc., a commercial wall and ceiling contractor, is based out of Lancaster, PA and serves the Pennsylvania, New Jersey, Delaware, West Virginia, Virginia, and Maryland areas. The company was established as a premier wall and ceiling contracting company by Jeff Mylin in 2005. “The emphasis was always on customer service and building a great team,” says a reflective Mylin 16 years later. “We focused on the needs of the customer and providing an end product that our team would be proud of.” As a result of this, Paramount has “experienced organic growth as opportunities presented themselves over the years.” Today, the company has nearly 100 employees, completes in excess of 300 jobs per year, and specializes in Metal Studs, Drywall, Insulation, EIFS and Acoustical Ceilings, as well as select Carpentry and Specialty items.

D&B is proud to have been partnering with a company that reciprocates our core values of being a company that cares about everything from the customer to the finished product. Since Paramount became a Trade Partner of D&B Construction’s nearly five years ago in 2017 they have worked on more than 10 projects with us, completing everything from insulation, drywall, and exterior sheathings to rough blocking, acoustical ceilings and clouds, and FRP.

Some of the current active projects Paramount is working on with D&B include this mixed-use design-build project in Kennett Square, PA, D&B’s new corporate headquarters, and Kreitz Gallen-Schutt Attorney’s office fit out, which is just starting up. Other projects worth highlighting from this year include Tower Health’s newest satellite office in Womelsdorf and Grove Dental Pediatrics.

Perhaps the most impressive job that Paramount is working on D&B with is the 80,000 SF adaptive reuse building currently being renovated in the heart of Wyomissing. This five-story building will be the future home of Stratix Systems’ headquarters.

Our Project Manager, Andrew, plays an active role in the daily management of what is occurring at the jobsite. This is what he had to say about his experience working with their team on this job: “Paramount has been an integral Trade Partner on our project at 200 N. Park Road in Wyomissing. Their Project Managers and Site Foreman have brought knowledge from previous projects on nearby, similar style buildings that have aided our project in design, constructability and schedule. Their crews have been more than accommodating with a stubborn building that has required much coordination and numerous details from the Architect.”

Andrew also had the pleasure of working with Paramount on three other projects, including his first job with D&B nearly one year ago, Kingsview Partners. He looks forward to “continuing our strong relationship with such a great Trade Partner” as we head into completing more jobs with them in the New Year.

Oh, and did we mention the Paramount team has some pretty great cooks, too?! This past October, Paramount was kind enough to host a home-cooked BBQ luncheon at Stratix Systems’ future new headquarters for all D&B employees, ownership, the project architect, RHJ Associates, and even invited us to invite other Trade Partners on the job. It was a great day of camaraderie onsite as we all learned about the intricate details of this detailed project. “Their BBQ was the launching point for one of our company’s on-site safety training sessions, and attendance was most definitely enhanced as a result of the promise of good food. We were and still are grateful for their efforts,” reflect Andrew.

We sat down with Jeff Mylin, President of Paramount Contracting, for a quick Q&A:

Q: Paramount Contracting has completed 4,100 jobs since its inception. What project are you most proud of to date and why?

A: “It is hard to choose just one, but the Ann B. Barshinger Cancer Institute in Lancaster, PA would be near the top. It is a respected facility in our home town and architecturally impressive building.”

Q: What’s the best piece of advice you would give to others looking to get into the industry?

A: “You have to have a love for the industry. Construction is a tough business with demanding schedules, tight budgets and currently material and labor shortages. Yes, there are many challenges but it also can be very rewarding when seeing the job come to completion. Those of us in this line of work understand how it feels to drive by a finished project and feel a sense of pride that ‘we helped build that.’”

Q: You are completing a number of projects with D&B right now. What has your experience been like working with our team?

A: “D&B projects are clean, organized, and safe projects to work on. They communicate clearly with all of the trade teams, which leads to successful projects. We have made a significant investment into bidding to D&B and we feel that has not gone unnoticed. Subcontractor loyalty is obvious, which increases effective teambuilding.”

Q: What do you enjoy most about working on a D&B project and why?

A: D&B Superintendents, Project Managers, Engineers, and support/admin staff are always accessible and willing to help. Coordination and scheduling are always well thought out and communicated from planning to completion. The jobs are often local, and our employees enjoy investing in the buildings in their community.”

At D&B Construction we like to think of our trade partners as an extension of our team. We are proud to call Paramount Contracting an extension of the D&B family. Every project we have collaborated with them on results in a final product that both teams can be proud of and that our customers can look forward to.

Ben, who will graduate with a degree in Media Effects from Penn State University’s Main campus this coming Spring, enjoyed receiving hands-on experience throughout his Summer internship with D&B’s corporate Marketing and Business Development team. As a Professional Writing Intern, Ben helped write articles for D&B’s blog through gathering research and interviewing team members. He also helped with various business administrative tasks that allowed him to learn to use Customer Relationship Management (CRM) software, our construction management software, Procore, and email marketing tools such as MailChimp, to name a few.

Although the majority of Ben’s three months with us was spent in the office, our team made sure to take him on active job sites. Ben was able to go to both commercial and residential job sites so he could see what both sides of the industry are like in person.

After completing his internship experience, Ben reflected on his time working with D&B, which he described as a “fun and valuable learning experience” for his future. Here’s a Q&A from Ben so you can learn more about his experience:

Q: What takeaways, including new skills, techniques, and knowledge did you learn throughout your internship with D&B?

A: “I thoroughly enjoyed learning the ins and outs of construction. The responsibilities I was given aligned with the classes I take at school, and I now have plenty of material that I can include in my portfolio as I start to job hunt post-graduation. I have developed better writing skills throughout the course of my internship. When I look back at rough drafts from my first article versus my rough drafts towards the end of my internship, I can see that I have made a lot of improvement. I learned how to use tools like Canva, which was useful. Ultimately, I was able to experience what it is like to work in marketing in the real world, which was a really good way for me to realize that marketing is a career I think I can pursue.”

Q: Did any of the classes you have taken in college directly prepare you for this internship?

A: “Yes! My media effects classes and writing classes prepared me for this internship. For example, my business writing class taught me essential skills to writing professionally. My media effects class taught me many things about how to effectively use social media. Actually, one of my assignments was similar to the benchmarking I did while at D&B, as I was asked to look at a celebrities’ Instagram accounts and analyze the good and bad things about them.”

Q: Did this internship make you re-consider what you want to do once you graduate college or confirm that you are in the right field?

A: “I have done a lot of thinking about what I will be doing when I graduate and start looking for a job. Even though I am not exactly sure what field it is that I want to work in, learning more about the construction industry and experiencing the environment in the office has definitely made me consider a job in this industry. I have also realized that I truly do enjoy working in Social Media / Marketing. Before this internship I thought that I would like a position like this, but I was never 100% sure. This internship also made me realize that there is nothing to be scared of, and I should go into the real world with all the confidence possible. Working for D&B has been a great step for me in finding a job once I graduate.”

Q: What are you most proud of from the work you produced throughout your internship and why?

A: “I am most proud of the articles that I worked on while I was here. I have always had to write for school, but writing for D&B’s Blog allowed me to have published work. I am proud to see the articles posted on the website.”

Q: How did you enjoy going on the job sites? Was the difference in commercial vs. residential jobs what you expected?

A: “I really enjoyed going to the job sites. It was cool to go on the job sites and see how D&B Construction works. Both residential and commercial job sites were completely new experiences for me. The difference is what I expected. The commercial job sites have a more hectic feel than the residential job sites because there are many more people working at commercial job sites.”

Q: What is your most memorable moment throughout your internship and why?

A: “My most memorable moment from my internship was visiting CHOP Souderton. I had never been to a commercial construction site and it was interesting to see the dynamic between the D&B Superintendents and our Trade Partners. I also thought it was really cool to see some of the obstacles they may face while building.”

For this quarter’s trade partner spotlight, we are taking a visit to Fleetwood, PA, where AP Merkel Inc. has resided since the 1890’s. AP Merkel is a four-generation company that offers plumbing, heating, and cooling services. They have come a long way since Augustus P. Merkel first founded the company over 100 years ago. AP Merkel first started out as a company that built farm implements, such as machines that would harvest crops. They are well known for manufacturing grain separators known as threshing machines.

Their transition into the HVAC world all comes down to a smart, strategic business move. “Eventually, all of these farms that AP Merkel was working with needed heat,” explains Nate Lobb, an Estimator who has been with the company for 10 years. One thing led to another, and eventually the company added plumbing into their wheelhouse. Approximately 30 employees later, “the rest is history,” sums up Nate.

Today the company is run by Pete Merkel, standing President, and busy with approximately 50 commercial jobs a year. Nate is usually efficiently juggling 20 or so jobs at a time, which he enjoys. “I like the diversity of projects we work on. We do everything from senior living, to coffee shops, to dentist offices,” he explains. Nate also enjoys working through and overcoming the challenges that come with starting every new project. “Being involved in a job from when it is just a concept in budgeting to when it is complete is something I always enjoy,” he says.

Nate, who received his plumbing license about five years ago, grew up in a construction environment. “My dad was always in construction. I had an interest more in the mechanical / HVAC and plumbing side of things,” he explains. Nate earned his Environmental Studies degree from Temple University in Philadelphia, PA. While in college, he interned for a company in Philly doing HVAC work and ended up coming back to the Fleetwood area and continuing his career at AP Merkel.

Nate stresses the fact that now is a great time to get involved in the industry. “There is a HUGE need for young, licensed tradespeople. There are few young people getting into this field right now. Get your license when you can, take it seriously, communicate, and you can have a great career,” he urges.

One young individual who has impressed Nate is D&B’s Superintendent, Ryan Hummel, who he has worked with since D&B Construction and AP Merkel established a relationship within the past year. “He has been really helpful and knows the industry, especially for being a younger guy. Ryan is really on top of it and not afraid to pick up the phone and check on something with us. We can talk through things and work it out. It is clear he takes his job serious,” explains Nate.

This feeling of open lines of excellent communication is just as strong a value for AP Merkel as it is for Team D&B. When we asked Ryan what he likes about working with AP Merkel, he summed it up simply in one word: “Everything.” However, what stands out most to Ryan is “their level of communication and coordination from their office staff to the field staff.” His experience working with AP Merkel over the last year has shown him that “they run a tight ship.”

An example of this can be found at one of our healthcare projects currently in active construction, Grove Dental Pediatrics. Ryan has worked with Nate and Tom, AP Merkel’s Superintendent who has been with the company for around 25 years. “I bid the Grove job, completed estimating, submittals, and the purchasing of equipment and piping, and Tom took it from there and is currently managing the actual job,” explains Nate.

One highlight of this 3,700 SF medical office space? “This project has medical gas piping, which is something we don’t deal with that often. This type of piping has to be put in very clean. It has a special fitting with a braised fitting joint. The key is to keep it clean, so when we start to install it we have to flush it with nitrogen gas,” explains Nate.

We recently visited this healthcare project in Wyomissing, PA. Here’s some photos of AP Merkel team members, Andy, Zach, and Scott, their lead plumber, working to keep the job running smoothly and safely with Team D&B:

White-sand beaches, warm weather, great food, and high-end luxuries are everything that Miami is known for. The small town of Surfside is no exception with its reputation of being pleasant, quiet, safe, and affordable. As you likely may have heard, Surfside recently become the center of attention for many people after tragedy struck the small town in June.

On June 24th Surfside’s 12-story beachfront condo, Champlain Towers South, partially collapsed at about 1:25 AM with its residents inside. As of Monday, July 26th, the last victim’s remains were identified. This brought the final death toll to 98 people after tedious efforts were made to account for every resident, and officials have now confirmed that remains for each person considered missing after the collapse have been recovered. The efforts made were the largest emergency unrelated to hurricanes ever conducted in the state, with search and rescue teams from throughout Florida, many other states, and even Israel and Mexico coming together to bring closure to families.

According to the New York Times, this disaster is one of the deadliest structural building failures in American History. Many residents are still in shock. Community Members Peggy Streter and her husband own The Carrot Café located in downtown Surfside. The two have claimed to know about 50 people who lived in the condo. The Streters are not the exception. Miami’s building chief, Charles Danger said, “Everybody in Miami knows somebody from that building or knows somebody who knows somebody.”

The rest of the building was demolished on Sunday, July 4th in efforts to continue the search. Once all remains were identified of those missing, officials began steering their focus to determining what could have caused the collapse. Since then the building has continued to be in the limelight, as many of the building’s records that would help investigators learn why the building fell could not be found, and the not-so-easy conversation over the fate of the site has started to take place. Here’s a quick summary of what is known:

Initial Concerns for the Condo

People living in Surfside Condos, which were completed in 1981, had previously voiced their concerns about the structure of the building they called home, so the collapse does not come as a surprise for some. After a DEA building collapsed in Miami almost half a century ago, taking the lives of seven employees and injuring 16 others, two Miami counties instilled new regulations requiring buildings that have stood for 40 years to be investigated for any problems. Since Champlain Towers South was in one of these counties, their mandatory 40-year inspection took place in 2018.

When the condo was inspected by engineer Frank Morabito in 2018, he identified that there was a flaw in the original construction of the building that was causing structural damage. Morabito mentioned the main issue was that the pool deck and outdoor planters had been “laid on a flat structure.” Since there was no slope where the pool stood, standing water was not able to drain off the pool deck. Instead, the water would sit on the waterproofed concrete until it evaporated. At the time of inspection, the water-proofing concrete had failed, causing the water to seep through resulting in “major structural damage to the concrete slab below these areas.” The report also pointed out distress and fatigue in the concrete, columns, beams, and walls of the parking garage below the pool area.

Morabito’s report said that “failure to replace the waterproofing in the near future will cause the extent of the concrete deterioration to expand exponentially.” He could not predict that this may lead to the collapse of the building, however he said that repairs to the concrete were needed for “maintaining the structural integrity” of the building. The waterproofing and structural issues of the condo were never addressed by the owner’s association.

Fast forward to 2019 when a neighboring luxury tower was being built. Residents of the Champlain Towers South condominium complained that construction would often cause their building to shake. This led to a resident and board member of the condo association, Mara Chouela, voicing her opinion that workers were “digging too close” to the property. She said they “have concerns regarding the structure of our building.” Just 28 minutes later, official Rosendo Prieto responded to Chouela stating that “there is nothing for me to check.”

There is no concrete evidence that construction of the condo’s neighbor contributed to the collapse of the building, and it is still unclear if the lack of action from the owner’s association was a major factor in the building’s collapse. Cassie Stratton, a resident who was inside the building during the collapse, reportedly told her husband on the phone that she saw the pool cave in first, backing up Morabito’s claim that the waterproofing of the pool was necessary to maintain the structure of the building.

The fact remains that residents were concerned for the structure of the condo, and they felt as if no one took the necessary action to redeem the structural integrity of the building.

Expert’s Findings

The city of Surfside hired a structural engineer, Allyn Kilsheimer, to inspect the site and determine the cause for the buildings collapse. Kilsheimer says it is “maybe not an individual cause, but two or three things that contributed and/or caused this failure.” While the pool could have been a major issue to the structural problems, it is still unclear and there are many theories that will be examined.

In addition to hiring Kilsheimer, another group was hired to lead the charge to uncover what caused the collapse since this was such a big case. The NIST (National Institute of Standards and Technology) will be working constantly to investigate the situation. They say that “a fact-finding investigation of the building performance and emergency response and evacuation procedures will likely result in significant and new knowledge or building code revision recommendations needed to reduce or mitigate public risk and economic losses from future building failures.”

How this Tragedy may Impact the Industry

Like many others, we have been wondering what caused this to happen. Matt Knight, Senior Estimator at D&B Construction, has been working in the industry for over 20 years. He has been involved with the construction of many large, well-known buildings, including the 9/11 Memorial.

Matt did not do any research, but from what he saw “the building collapsed from the bottom up,” which makes him think “there would be structural cracks in the floor, columns, beams, etc.” As we know now, these structural cracks were found by engineers and deemed to be a major structural concern prior to the collapse of the building. Much like Allyn Kilsheimer, Matt believes that it is likely there are multiple causes for the failure of Champlain Towers South.

One of the theories that Matt believes had a big role in the building’s collapse was the fact that the condo had been sinking at a rate of two millimeters per year from 1993 to 1999. Scientists also discovered evidence of other areas nearby sinking as well. Matt says that one of the most important things when constructing large buildings is to make sure you are building on good soil. Since the condo was slowly sinking, Matt believes they likely “built on unsuitable soils and never got the compaction they needed.” He notes that if soil is not properly compacted so that it is suitable for the building, everything else will eventually fail. “If you are building from the ground up your soil underneath is, of course, most important,” he concludes. For now, Matt is waiting to learn more about what caused the failure once the investigations are conclusive.

What we can Conclude and How to Move Forward

At the end of the day, the collapse of Champlain Towers South was a tragedy, however Matt tries to look at how the industry as a whole can learn from what happened. “Usually a lot of good things will come out of a catastrophic failure. For example, we learned a lot from 9/11, and today those World Trade Center Towers are not being built the same way,” he says. Matt believes the industry will learn valuable lessons from this, and it will improve how we are constructing buildings overall. He would not be surprised if there will be changes for older building’s codes, especially around that area. Matt also proposes the idea of a new law emerging from this that would make building owners, when aware of structural damages, either make the repairs or move everyone out until they do.

While we wait to learn more, one question many still have is whether or not limitations on technology when the condo was built play a factor in the failure of Champlain Towers South? When the condo building was constructed in 1981 many of the rules and regulations that we have today were not in place. Miami was also known for “slipshod construction,” and in some cases they were known to take the look-the-other-way approach when enforcing building codes and regulations. While their construction practices were not nearly as good then as they are now, they also did not have access to the technology we have now.

Specifically, VDC (Virtual Design and Construction) and BIM (Building Information Modeling) are tools that Matt says, “could have helped if they had it during original construction”. BIM is a tool for 3D modeling and data input of physical objects, while VDC uses BIM models to plan the construction process from beginning to end. Watch a video to learn more about VDC and BIM here. Using technology like BIM and VDC essentially allows you to build the entire project virtually before building it in the real world, which can decrease cost and time put into a project while also increasing safety. We may often take technology like this for granted, but it is interesting to think about what the world of construction would have looked like in the 80’s if society had access to these technologies that we can now use every day.

D&B is interested to hear your thoughts. Do you think new technologies will help to prevent disasters like the one in Surfside? What policies and procedures do you think should be put into place to help increase safety and avoid disasters such as this from happening in the future? Let us know in the comments below!

Open floor plans in office spaces first made an appearance in the 1940s and later evolved in the 1960’s where they were used as a means of symbolically showing the company’s culture. Offices with open floor plans continued to be prevalent during the tech boom of the 1990’s, and in 2005 they became a real inspiration for innovation.

In 2005, Google completely renovated their headquarters signaling the “dawn of a new professional era.” The project architect, Clive Wilkinson, explained that they got rid of the cubicle because of Google’s “We’re inventing a new world, why do we need the old world?” attitude. Many companies followed suit in later years, asking to be “Google-fied.” Just 10 years after Google’s office transformation, Facebook would follow suit, creating an office space that held 2,800 employees across 10 acres. The headquarters would claim to be the largest open floor plan office in the world.

Offices with open floor plans have become a major trend in recent years. Although they all don’t span across 10 acres like Google’s may, they still pose a timely question as people return to the workplace: Will this office layout and design work in a post COVID-19 world?

As the world rethinks how we work, it will be interesting to see how office layouts as we know them will transform in the upcoming years. Companies currently looking to re-imagine or add onto their office space may currently be weighing the pros and cons that an open floor plan offers. Let’s take a look at some of them:

Pros and Cons of an Open Floor Plan

One of the biggest arguments supporting the open floor office design is that it provides the employee with a unique social aspect that other office designs do not offer. The social interactions in an office can provide a large system of support to your employee, helping with the individual’s motivation and overall productivity.

Depending on its design, an office can provide a balanced social and cognitive environment for their employees. When optimized, an open floor office design will have a good mix of spaces that are intended for different uses and easily adaptable to fit the employees’ specific needs.

One way that our team at D&B likes to incorporate an open floor plan into a re-imagined commercial office space is through installing aesthetically pleasing glass doors throughout. This trend gives companies a modern, sleek and updated look. An example of this look from one of our past clients can be found in Power Kunkle’s large conference room.

Although many would argue that open floor plans are here to stay, some would dispute that noise, a lack of privacy, and opportunity for distraction may cause an increase in errors, lack of production, and sometimes stress with this layout design. In 2018, the Harvard Business Report found that “open offices reduce face-to-face interactions by about 70% and increase email and messaging by roughly 50%.”

This quick look at the pros and cons of an open floor plan illustrates that this design is not a one size fits all solution. Members of Team D&B believe that transformative office spaces will increase in demand, and it looks like the latest research agrees.

Transformative Offices: The Solution to Future Commercial Office Space

As businesses leaders look to redesign their office space in the near future, they will need to think of how they can cater to different employees and their varying workflows. Some may thrive on collaboration and interaction, an essential component to build company culture, foster relationships, and create a team-oriented atmosphere. On the other hand, there will be times when some employees may be more productive in a quiet environment where they can focus. The solution to these varying needs? A transformative office space.

D&B Construction’s Pre-Construction Manager, Bob Martzall, has noticed that “some businesses have been expressing their desire to have flexibility” as they work with D&B as their general contractor. One way they are achieving this goal is through modular walls. Bob explains how “modular walls can provide an office with a great amount of flexibility and safety, as these are walls that you can take down, move, or shift.”

On a larger scale, one company that has taken flexibility to a whole new level is Salesforce. In February of this year they announced that employees would “have the option to work remotely full time, even when it’s safe to return to the office.” Their new guidelines offer employees the option of working full remote, flex time in the office, or completely office-based. Employees who choose to work the “flex” option will have the flexibility of coming into the office between one and three days per week when they need to perform tasks that may prove challenging over a video conference call, such as working on collaborative projects or meetings with clients. So how will this extensive change affect the company’s 19 physical offices in North America alone… specifically the recently completed 1,070-foot-high Salesforce Tower in San Francisco? The company has announced that they will be redesigning offices as “community hubs” that will replace rows of desks with multiple collaboration and breakout spaces.

D&B Construction’s Philadelphia office recently completed a 10,246 SF commercial office design-build project for Berger Rental Communities at their new West Valley Business Center location in Wayne, PA. Their new collaborative room is one of their employees’ favorite spaces. Lesley Yocum, a Project Manager out of D&B Construction’s Philadelphia office who also played a major role in designing the client’s space, said that they knew they wanted this space throughout the entire design process.

Research looking at today’s high-functioning workplaces show that employees are spending much more time on collaborative activities. Lesley agrees – especially right now. “People are returning to a ‘new’ office layout with more space between their co-workers. Because of this, collab rooms will be utilized as both old fashioned conference rooms and a place where you can go to get ‘comfy’ and discuss since that’s what many people are accustomed to now after working from home for so long.”

Community Space May Be Key

Unique spaces in open floor offices can include coffee bars, lounge areas, and other spaces designed to make everyone feel welcome, while still encouraging open communication and collaboration. This welcoming environment can be found at D&B Construction’s most recently completed project for Riverfront Federal Credit Union, who just held their ribbon cutting ceremony on June 16. The credit union’s newest branch and Operations Center features cutting edge technology with a drive thru consisting of three Interactive teller Machines (ITMs) and self-service kiosks offering Video Integrated Realtime Assistance (VIRA). Inside their new 34,000 SF office space, you will find that Riverfront’s strong belief in the value of face-to-face banking has not been lost. The interior is set up in a manner that’s more interactive than a traditional bank, and members are welcome to relax in a comfortable seating area while they complete financial transactions. A café will soon be open to the public as well, further promoting a sense of community. Learn more about this project and how it has created a grand customer experience through both technology and in person banking options here.

Embracing Technology for Everyone’s Safety

As D&B’s recent project with Riverfront Federal Credit Union depicted, and to no one’s surprise, an even stronger emphasis will be placed on technology as the future of work evolves. One way we are already seeing this? Our clients want their conference rooms to be decked out with cutting-edge technology that will allow them to host video conference calls in their meeting spaces. Our Pre-Construction Manager, Bob, has already seen rooms with cameras and microphones that are set up to instantly switch over to the person talking and simultaneously broadcast them to the Zoom meeting. A room like this is something businesses may want to seriously consider if they are designing an open-floor plan, especially if they predict to be in a hybrid working environment.

Bob predicts we will see “more hands-free devices and more technology-oriented safety” in the near future. This can include investing in Bluetooth technology throughout conference rooms so employees don’t have to touch a speaker or shared phone. Doors can also be fully controlled by an app on your phone or simply don’t need to require handles and can instead swing open both ways by pushing them with your shoulder or foot. Hands-free water dispensing systems are another trend that Bob has noticed. Want to be health conscious while also looking out for the environment? Try installing motion lights throughout the office, from conference rooms to bathrooms.

Limiting high touch point areas such as door handles strongly reduces the spread of germs, and for this reason, Bob imagines these current trends are here to stay for a long time. Case and point: The upscale conference room D&B completed for Berger Rental Communities’ new headquarters at the end of April included a specific wall mounted camera with multiple speakers in the ceiling, motion lights with sensors throughout all offices, and dimming lights throughout all other areas. View more photos and learn more about this project here.

Moving Forward Post Pandemic

A study by USA Today shows that 35% of Americans prefer a home-office hybrid working situation, and 25% of Americans want to go back to the office full time. With over half of the population hoping to return to the office in some capacity, the question of how employers will accommodate for safety concerns and the “new normal” of flex time still looms over many individual’s heads.

Bob believes safety will determine many office designs post COVID-19. He thinks that one of the most important things to include in your post COVID-19 office is environmental air filtration systems. This refers to how the air circulates through the office so that it is environmentally friendly, limiting the spread of germs and being sustainable. Bob has seen clients wanting to have this included in their project design.

Having more collaborative rooms may result in a more open floor plan being replaced with more individual office spaces (which may help some individuals feel more at ease with returning to the office). With 36 years of experience in the industry, Bob has noticed that “many offices are shifting away from a cubicle environment and instead building more individual office spaces.” He believes that building more office spaces can make it much easier for an employer to provide safe precautions for their employees when necessary, thus explaining this recent trend. These adaptations can make a work environment flexible and safe for everyone involved.

As many companies continue the transition of shifting back into the office, Bob has noticed that companies across all sectors have been trying to get their projects fulfilled by construction companies. He says that this is because “the cost of borrowing is so cheap right now, so the cost of doing business is more economical. The question is, do you need the space?”

The companies who answer yes to this question (and companies such as Salesforce who need to re-imagine their spaces) will be left to map out how their office space should look in a post COVID-19 world. In some way, shape, or form, many businesses will have to change their office footprint in the upcoming years, whether through down-sizing, expanding or renovating their current space to fit future needs. This is something that is weighing heavily on the minds of many employers. Although daunting at first thought, this is an opportunity to create a new blueprint that sets the stage for office spaces for years to come.

After considering the thoughts of our industry experts, years of research, and the current state of the world, how would you design your office’s blank slate to best meet the needs of your team?

We’d love to hear your thoughts and ideas in the comments below!

With the prospects of a slightly warmer than average summer looming, it is important that those within the industry, and anyone working long hours outside, brush up on their knowledge of high heat safety. At D&B, safety is our standard. Our Safety Committee meets monthly (and will actually be discussing this relevant topic at our upcoming meeting) to help ensure that all members of our team and trade partners are safe. In the name of safety and looking out for our brothers and sisters in the industry, we wanted to share these helpful tips from D&B’s Safety Director and Construction Manager, Tom Rinaldo:

1. Stay Hydrated

Tom suggests that all D&B employees and trade partners stay well hydrated during the summer by drinking one cup of water every 15 to 20 minutes. On every D&B jobsite, we provide ample amounts of water for our employees and trade partners. It is important to hydrate the night before and after you work on a jobsite. Doing so puts less strain on the body to replace the fluids you have lost while sweating.

If water is not easily accessible or you are looking for an alternative, Tom recommends trying drinks that have electrolytes, like Gatorade. Gatorade contains valuable electrolytes that can help maintain the ionic balance in your body. Gatorade and similar drinks are also able to replace electrolytes that you may have lost while sweating, and having enough electrolytes is vital to keep your body functioning properly while on the jobsite.

2. Avoid Salty Foods

Tom urges team members to avoid eating salty foods. Why? They dehydrate you. Foods such as pretzels, potato chips, and popcorn can be a great snack, but in the summer months you may want to trade them in for your favorite fruits and veggies.

It can be hard to avoid eating salty foods on the jobsite, especially since the convenience of fast food restaurants can be tempting when you’re on the go. Fast foods like McDonald’s can be unhealthy – and even unsafe during the summer months – for more reasons than just its high sodium content.

Let’s say you’re on your way to the jobsite and decide to stop at McDonalds to get a classic Big Mac Meal with fries and a soda. This meal is 1,320 calories; 51 grams of this is fat, 192 grams is carbs, and 1,425 mg is sodium.

Construction workers can burn up to 300 calories per hour while on the job. This is three times as many calories as the average office worker who only burns around 102 calories per hour. Because of this, it is recommended that individuals completing manual labor on the jobsite consume at least 2,500 calories a day. After eating your Big Mac Meal, you have already consumed 79% of your daily fat, 64% of your daily carbs, and 60% of your daily sodium, and you still need to consume 1,180 more calories to obtain the recommended 2,500 calories.

Not only are you consuming too much sodium, but regular consumption of fast food meals such as this can be unhealthy to you and may even influence other workers to follow suit. To stay healthy on the jobsite, we recommend packing protein and complex carbohydrates low on salt, with some healthy snacks (see the next tip for more info on this).

Start your day off right with this easy to make breakfast burrito. For lunch, try saying adios to the usual cold cuts and deli meats high in sodium and nitrates by trading them in for the ultimate trifecta: something delicious, healthy, and safe for your body in the heat. We think this Protein Packed Pasta Salad looks delicious! While you are feeling inspired, check out these 15 tasty and uncomplicated lunches that are packed with protein.

3. Eat Water-Filled Foods

Watermelons, strawberries, oranges, peaches, cucumbers and other fruit are great snacks, especially in the summer while on the jobsite. In addition to drinking water, eating water-filled fruits and other snacks is a great (and healthy) way to stay hydrated.

One great lunch option is a cucumber-watermelon salad with avocado and bell pepper. Aside from being tasty, it is simple, too! All you need to do is cube these foods and add the dressing of your choice.

Another very simple – yet effective – snack that will keep you hydrated is frozen grapes. Find more inspiration for delicious recipes that will help keep you hydrated here and here.

Let us know which recipes you’d like to try and what your go-to healthy lunch is on the jobsite in the comments below!

4. Wear Loose, Light Colored Clothes

Darker clothes attract more sunlight. Naturally, this rule applies on the jobsite in the summer. Our Safety Director, Tom, suggests this simple tip that can make quite the difference: wearing loose, light-colored clothes.

5. Get Some Shade

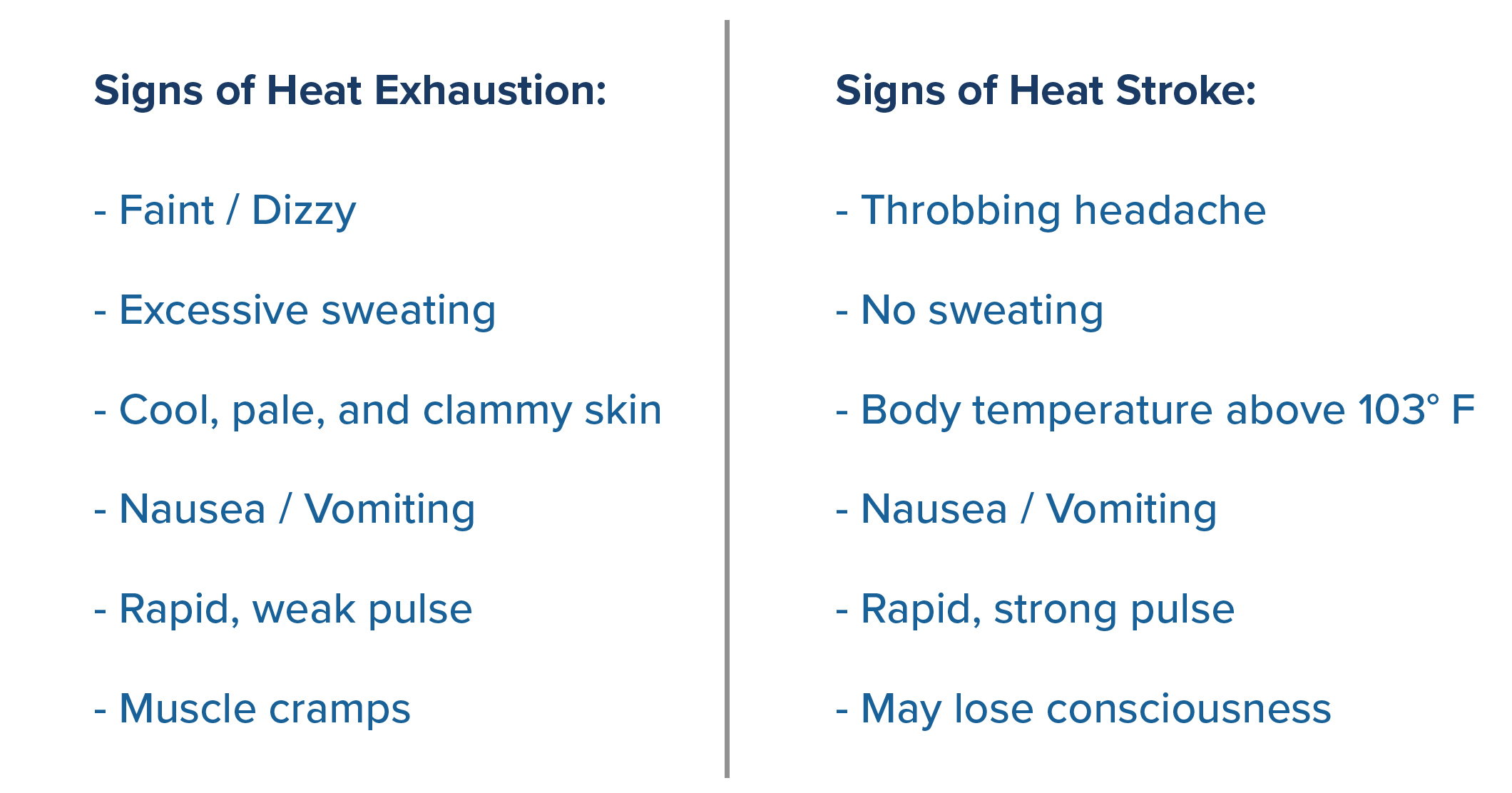

Potentially the most important tip out of the five, make sure to get some shade. Naturally, jobsites can get extremely hot in the summer months. Our Safety Director encourages all workers to take breaks in the shade to cool down and to be vigilant for signs of exhaustion, both for themselves and their co-workers on the jobsite. Having a buddy system may work well here. It is important to watch for the following signs of heat exhaustion and heat stroke for everyone on the job:

The Benefits of An Acclimatization Plan

Implementing an acclimatization plan is one way to prevent heat exhaustion. Simply put, this allows workers to get used to the high-heat conditions of the summer. This should take place over a one to two-week period. For new workers, the schedule should accommodate for no more than 20% exposure to heat on day one, with an increase of no more than 20% each day. If the worker has had experience on the job, you should do the same sort of process over a four-day period. Start day one at 50%, move to 60% on your second day, and 80% on your third day. By the fourth day you will be at 100% exposure. Tom supports this kind of plan if he feels the situation is right for it, although the tri-state area that D&B covers usually doesn’t require this since the seasons are well-balanced.

Trend 1: LEED and Green Building

“A ‘Green’ building is a building that, in its design, construction or operation, reduces or eliminates negative impacts, and can create positive impacts, on our climate and natural environment. Green buildings preserve precious natural resources and improve our quality of life” (WGBC). In response to the COVID-19 pandemic, Green or LEED construction is changing. The U.S. Green Building Council, creators of the LEED certification, plans to promote healthier and safer air quality indoors with adjusted certification criteria incentivizing the creation cleaner air systems. In 2021, there will be more building materials and components that help get LEED certification. One interesting and somewhat new development is a form of self-healing bio-concrete. This is a compound of concrete and bacteria that produces limestone when exposed to air and water, which helps with the impermeability of the surface. It costs around $240 per cubic meter. For reference, normal concrete usually costs between $200-$300, making it still cost efficient. Green building will continue to grow throughout the next decades and new technology and policy will come out to reinforce it as time goes by.

Trend 2: Modular Construction

The construction industry is rapidly moving towards modular materials because of its cost and time efficiency. Modular building is anywhere from 20% – 50% faster than traditional construction. It is also around 20% more cost efficient to build modular instead of traditional because of the reduced labor and time costs. Modular building also cuts the waste output almost in half due to optimal fabrication and pre-planned units. Everything is built off the construction site, which reduces the challenges of regular construction such as weather, limited working hours, and space. Overall, modular building is great for symmetrical and repeating buildings where sections can be made and stacked or attached to each other easily like in apartment or office buildings.

Trend 3: Safety

As it should be, safety is a huge trend in 2021. The old workplace safety system focused on recognizing problems and fixing them after someone gets hurt or a problem occurs. The new system getting pushed in the industry is based on prevention through education and training and recognizing issues before anyone gets hurt. This is why we have our Safety Committee meet monthly to discuss different topics of safety. Another large change in the safety category is better technology with Personal Protection Equipment (PPE). With more women entering the field, there is an increased awareness of the need for PPE to properly fit all employees to ensure safety. In addition, because of the COVID-19 pandemic there are policies across most companies including D&B that promote safe environments using masks, social distancing, and sanitization. When the pandemic hit, our team implemented a sign in and sign out sheet at every job site, making it easy for us to accurately perform contact tracing in the event that someone developed COVID-19 symptoms. D&B will continue to enforce this rule across all job sites moving forward. Learn more about our safety standards here.

Trend 4: Multi-Family

Multi-family construction is one of the fastest growing sectors of the commercial construction industry. Because of the lack of inventory in the housing market and changing demographics, multi-family construction is in high demand and will continue to grow in the following years. More people are looking for smaller, more affordable homes and condominiums with less maintenance than a normal single-family house. Research shows that 33% of people who are reaching age 55 are on their own. This is much different than what was the case 20 years ago. Currently D&B has multiple multi-family jobs under active construction and in the pre-construction phases. Throughout my internship, I shadowed the construction of The Reserve at Gring’s Mill, which you can view here.

Written by: D&B Intern, Alex Wolf

Alex culminated this list based on what he learned during his time at D&B. He is a Senior at Wilson High School who began shadowing various D&B employees in September of 2020. Alex will be attending Virginia Tech for Architecture in the Fall. “My internship experience at D&B made me realize that I want to pursue a career in residential remodeling and construction,” he explains. “I gained a lot of knowledge about the construction process and enjoyed being able to see entire construction projects from start to finish.”

On February 22, 2021, we celebrated our 10 year anniversary! This milestone is something to celebrate. According to historical data from the Bureau of Labor Statistics, the construction industry has one of the lowest business survival rates. About 25% of small construction companies don’t survive their first year, and labor statistics also show that 70% of these businesses never make it to their 10th anniversary.

From flipping homes and completing renovations, to building entire custom homes from the ground up, to entering the commercial construction industry and completing over 5 million SF since then… A lot has happened in the last decade. We owe it all to our amazing team members, trade partners, suppliers, clients, friends and family! Thank you for being part of this journey, and we look forward to what’s to come in the next decade!

Reflecting on 10 Years

Q: Any fun memories or stories that you’d like to share?

“When I first started at D&B we were much smaller, with offices across the hall. I was excited to work for Al, Dan and Brennan because there was an underlying positive energy that was contagious. I remember Brennan bouncing his ball against a wall when he would visit our side, driving us all crazy, and Dan running through the office saying “coming through”. When Tom started we made him a make shift desk in the copy room. It was a little rough and we made it work. If you ever need anything go to Adam, he is our historian and remembers everything! We have grown so much in the five years I have been here, and it has been fun being part of that growth both personally and professionally. I work with the best team! They happily share their knowledge, teach me something every day and challenge me to grow. They are my extended family. I also want to thank Al, Dan and Brennan for giving me an opportunity to be a part of a great team!”

-Beth, Project Coordinator

“When I first started we were limited on office space at the Park Road office. I was sharing an office with three other team members. Within a week, I adapted and found a corner in the room where the printer was. I made a desk from cardboard boxes and an old countertop. Talk about improvising. It actually worked well. HA!”

-Tom, Construction Manager & Safety Director

“I remember the first time I met Dan & Brennan when they first got started 10 years ago. I was on the other side of the job as an inspector for Lower Heidelberg Township. I believe they were constructing a deck, sunroom or an addition somewhere in the Green Valley area. I came across a lot of contractors in my 13 years as a building inspector, but always remembered them from the first meeting. Great guys with a goal of doing it the right way! This 10-year anniversary is a testament to them honoring their commitment to doing things the right way for their clients, employees and themselves!”

-Andrew, Assistant Project Manager

Q: How have you personally grown since first starting at D&B? What have you learned?

“The importance of teamwork. D&B has shown me what can be accomplished when there is a team that will support you from top to bottom.”

-Matt, Project Manager

“I have grown my leadership skills tremendously, and I learned that I can actually make a difference.”

-Tom, Construction Manager & Safety Director

“I’ve been here since January of this year, but I feel like it’s been much longer. The team has accepted me, and I love the company culture. I have learned a ton about our processes, software and my teammates. The ‘go-getter’ attitude of our leaders has me extremely excited for the future!”

-Andrew, Assistant Project Manager

Q: How have Dan and Brennan evolved as leaders since you began?

“They are evolving into awesome leaders. The growth that the joint venture of Metro and D&B bring are endless. They always have and always will have each other to bounce ideas off of. Not one decision is made for the company without them both discussing it together.”

-Alex, Superintendent

“Dan and Brennan are growing as leaders since I started and will continue to grow with the company.”

-Tom, Vice President of Construction for the Reading Division

Q: When you think of your D&B family what is the first thing that comes to mind?

“Teamwork. A commitment to excellence and doing things the right way for the client.”

-Andrew, Assistant Project Manager

“Compassion and understanding.”

-Matt, Project Manager

“Unbelievable teamwork and teammates.”

-Alex, Superintendent

“Teamwork.”

-Tom, Construction Manager & Safety Director

“Cooperation.”

-Barry, Superintendent

Q: Anything you want to say to the D&B team as a whole?

“Keep up the good work and adapt with the growth.”

-Tom, Vice President of Construction for the Reading Division

“I would like to say thanks to everyone. Many people in the company reached out to me when my mother passed, and it means more to me than they know.”

-Matt, Project Manager

“Being a part of this team makes me feel so proud. It’s a breath of fresh air knowing I can rely on our team for help or ideas. As long as we stick together and use all of our teammates, there is nothing we can’t do!”

-Alex, Superintendent

Q: How would you define our company culture in a few words?

“Teamwork. Cohesive. Fun!”

-Andrew, Assistant Project Manager

“Engaging, welcoming, team oriented, rewarding, flexible, motivating and connected.”

-Alex, Superintendent

“Teamwork and striving for excellence.”

-Matt, Project Manager

“The culture here is unique compared to other companies.”

-Tom, Vice President of Construction for the Reading Division

Q: What do you love most about working at D&B?

“The challenge to keep up.”

-Barry, Superintendent

“Everyone has been extremely helpful in bringing me up to speed and getting me involved in as much as possible. The work atmosphere is fun, all while getting the tasks accomplished in timely manner. It is a great team with great balance across all facets.”

-Andrew, Assistant Project Manager

“The people. Everyone is down to earth and is there to support whenever possible. In times of need, D&B employees have been there to lend a helping hand or provide insight on an issue on a project.”

-Matt, Project Manager

“Mentoring the younger team members and watching them grow.”

-Tom, Vice President of Construction for the Reading Division

Learn More About D&B

If you follow our social media, you’ve likely seen our YouTube series reflecting on 10 years to celebrate the company’s milestone. Catch each episode here:

Episode 1: Dan and Brennan, and their wives, Urs and Jenny, reflect on the many different office spaces we’ve had throughout the last decade. Learn more about how we went from an office space in a house Dan and Brennan ended up flipping to where we are today.

Episode 2: Dan and Brennan discuss how D&B has grown in the last 10 years and whether or not they expected to be where they are now.

Episode 3: Did you know that Dan and Brennan were teammates long before they started the company? They played soccer together at Elizabethtown College (where they were also roommates). Learn how they have grown over the years and how their partnership complements one another.

Episode 4: This episode focuses on our most important asset – our team! In the words of Dan and Brennan, “Our team is what got us here today.” Dan, Brennan, and their wives recognize and celebrate everyone who makes up the D&B family.

Episode 5: Dan and Brennan’s family send their congratulations to Team D&B on their 10 year anniversary. Plus, you’ll learn what some of the D&B kids love most about visiting their dads and the team at the office.