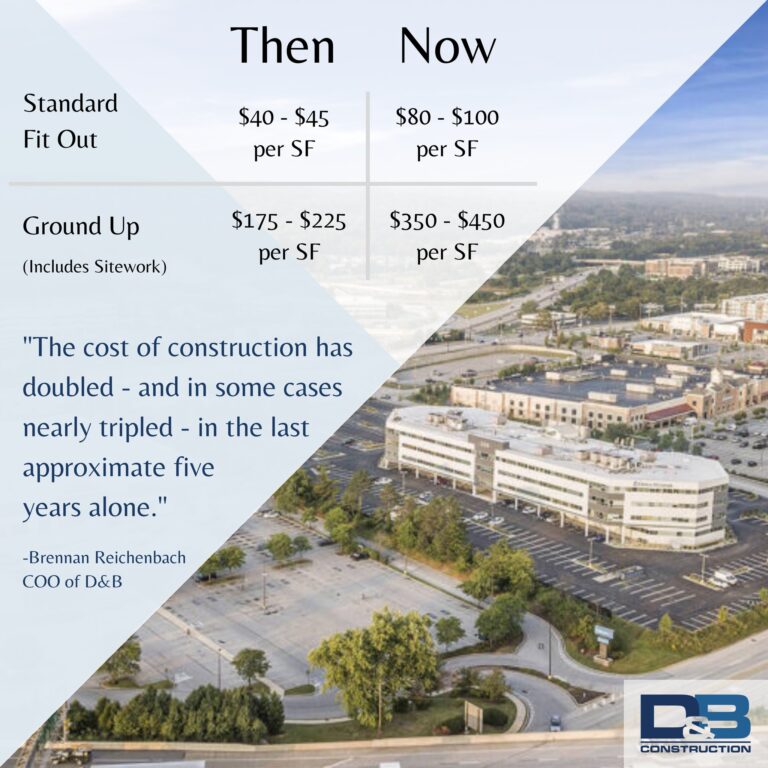

“Tenant fit out” is a common phrase you will hear used throughout the industry. It refers to the process of making an interior space ready for occupation. Usually, it is common practice in commercial construction to keep the interior space empty so occupants can create the look and feel of their business while determining the level of refurbishment they need. While an office renovation refers to the work needing done to improve an interior design (think aesthetic revamps such as purchasing new furniture or fresh paint), a fit out involves creating a usable area within an empty space.

The Different Types of Commercial Fit-Outs

A Category A fit out is the standard for what you will find in commercial space ready for renting, with utilities such as plumbing fixtures and electrical wiring already in place. Typically, features like electrical outlets, HVAC systems, fire protection systems, raised access floors and toilets would need to be installed yet.

On the other hand, a Category B fit out requires installing features that are lacking in a Category A. In sum, this fit out focuses on making the aesthetic design specific to the business. It typically involves installing lighting, flooring, painting, partitioning, window treatments, furniture, and branding to make the office yours.

A core and shell fit out refers to a space that already has the framework of the building in place and is ready to be custom fit to its specifications. These fit outs typically include the following tasks:

-Floor installation

-Partition walls

-Ceilings

-Power and Lighting

-Painting

-Furnishings and fixtures (such as casework and millwork)

-Changes or updates that may be needed for structural elements of the space, such as the placement of windows and doors

-Updates that may be needed to HVAC (such as extending into other spaces with ductwork and controls), Electric, Sprinkler systems, etc.

-Cabling and wiring for internet connectivity and communication arrangements (fire alarms and other protection systems)

What to Consider When Contemplating an Office Fit-Out for Your Business:

Fitting out an office space for your organization is a big undertaking that – when done correctly – can have a lasting impact for many years to come. It all starts in the pre-construction phase, where the proper planning and design of your space will ensure a smooth project throughout the duration of construction. Here are a few things to consider:

-An office fit out is an organization’s opportunity to take a blank canvas and make it their own. Consider how you can organize your space to increase workflow and enhance your staff’s performance. Do this by evaluating how the workspace will be used and all that needs to be in it for your team to efficiently complete their jobs.

-Plan for the future. If you ask yourself questions like “How will my business / industry grow and change over the next few years?” and “Will the proposed space be able to accommodate expansion in the future?” you can avoid needing to make renovations sooner than you’d like. As a result, your organization will save money by avoiding having to interrupt business to make changes to your office space.

-Make flexibility top of mind. Consider how technology advances and new trends may impact your office’s workflow. Does your space have the flexibility to adapt to such rapid change?

The Right General Contractor Makes all the Difference:

Most importantly, make sure the people you surround yourself with during this process are reliable, organized, and great communicators. A good General Contractor will help you navigate all of the points listed above.

D&B Construction Superintendent, Joseph, is no stranger to Tenant Improvements, regularly completing fit-outs for our clients like Cardiology Consultants of Philadelphia. He shares some tips on what to look for in the right GC for the job:

-Your GC should provide a dedicated project team to oversee your fit out. In order to make sure the job runs as smoothly and efficiently as possible, your GC should lead the project team in meticulously going over your project’s logistics and specifications in pre-construction. This may include working with your property management team, building architects and engineers, and other tenants in your building.

-Look for a conscientious GC who is actively working out and updating schedule details to limit any type of disruption or inconvenience to your current operations. A constant open line of communication and attention to detail ensures your project is completed on time.

-Weekly client meetings organized by the contractor of your fit out are a good way to ensure you are always fully aware of your project’s progress. Regular touch bases also enable the team to target any changes that you may want to make during the course of construction.

-A good GC will have a well-established relationship and open line of communication with their subcontractors. At D&B, our team works hand in hand with our trade partners to achieve perfection on your project. Our high standard of cleanliness, safety, and quality of work shows through the duration of the project.

“The bottom line comes down to this,” explains Joe: “When the project is completed the client should feel like we exceeded their expectations of the finished product. Starting with the pre-construction team and ending with the final cleaning of the project, we take extreme pride in the work we deliver, as well as the relationships formed with our clients. This makes all the difference.”

A transitional photo showing the before and after shots throughout one of our many medical office fit outs

for our client, Bucks County Orthopedic Specialists.

Technology is ever-evolving, and part of this evolution includes the construction industry. In response to COVID-19 and technological advancements, the construction industry has begun to innovate more than ever before. One of the most fascinating practices that is growing in popularity is modular or off-site construction.

Modular or offsite construction is the process in which a building is constructed off-site under controlled conditions using the same materials and built to the same standards as conventionally built facilities. The only difference? It can be built in nearly half the time. Buildings are constructed in modules that can be put together to form the original design, all while still resembling the work of the most sophisticated site-built facility. Why do companies use modular construction? The answer is simple. Modular construction is greener, faster, and safer.

A Greener World with Modular Construction

Since modular construction is a factory-controlled process it generates less waste and creates a site that is less likely to evoke disturbances. A modular construction site also promotes more flexibility and re-use. Modular projects can be disassembled and relocated or refurbished for new use. This reduces the demand for materials and limits the amount of energy used to create a building that meets the new needs. Additionally, a modular site produces less material waste since the building is constructed in a factory and waste is eliminated by recycling material, controlling inventory, and protecting building materials.

Finish Projects in Record Time

Modular construction is also faster than traditional building methods. Construction of modular buildings occur while site and foundation work are both being done. The Modular Building Institute reports that this can reduce construction times by 30%-50%. This can also be credited to the elimination of weather delays. Sixty to ninety percent of construction is completed inside of a factory, leaving no need to worry about inclement weather delaying a project.

Staying Safe with Modular Construction

One of the most important benefits of modular construction is safety. As we know, safety is always a priority in construction, and modular building makes it easier than ever to be safe. A report by McGraw-Hill Construction found that over 1/3 of their respondents (34%) who are currently using modular construction have seen site safety improve. This may be credited to the fact that it is free from weather elements like rain or snow that can cause slips and falls. It also reduces the risk of a worker falling from great heights, which OSHA reports as the cause of 33.5% of construction worker fatalities. Learn more about OSHA and their dedication to safety by reading this article on D&B Construction’s blog.

Modular Construction: How It’s Done

Modular building is done mostly on the ground level, but if working from height is required permanent scaffolding is used. This permanent scaffolding is different (and safer) from the scaffolding normally used on a traditional job site. Because it is not constantly being moved and reassembled, there is less likelihood for error and accidents.

Modular construction is growing in popularity. According to Fortune Business Insights, the global modular construction market is going to be valued at $114.78 billion USD by 2028. The market was valued at $72.11 Billion USD in 2020. Here are some examples of just how much you can do with modular construction:

Star Apartments, Los Angeles, 2014

The Star Apartments in Los Angeles were built in 2014 on top of a previously existing single-story commercial building. A concrete superstructure was poured over the existing structure. Next, five stories of modules that were built off-site were added on top of the single-story commercial building. The modules were stucco-finished on site. These modules provide 102 apartments and have pre-installed bathrooms, appliances, cabinets, and surface finishes.

Habitat 67, Montreal, 1967

An iconic example of modular construction is Habitat 67. Built in 1967, architect Moshe Sadfie’s unique cuboid block of 158 apartments caught the eyes of many. The way Sadfie designed Habitat 67 allowed for 15 different kinds of housing, gardens and terraces to fill the voids in between. The complex stack of concrete houses was connected by high-tension rods, steel cables, and welding. Even though it was built in 1967, Habitat 67 shows the true possibilities of modular construction.

Nakagin Capsule Tower, Tokyo, 1972

This 14-story tower was the world’s first example of permanent modular construction. The building has 140 self-contained, prefabricated concrete capsules that each measure 2.3m x 3.8m x 2.1 m. The capsules were each connected to the shaft of the building with just four high-tension bolts, allowing each unit to be replaceable if needed. These capsules were delivered to the site already fitted out with a small bathroom. Owners used the capsules as small living or office spaces, and the interior space of each module can even be extended by connecting to other capsules.

These are three unique examples of modular construction because of their structure. While these extravagant and unique designs are made easier with modular construction, you can also make very basic structures that look identical to buildings that are constructed on-site. The possibilities with modular construction are seemingly endless thanks to its ability to make construction greener, faster, and safer. We look forward to seeing just how far modular construction will go.

As the world seeks ways to be more environmentally friendly, many big industries have made changes to be sustainable. Construction has joined in on these efforts, paving the way for a more sustainable future.

Our industry has the unique opportunity to significantly impact climate change for the better since a large amount of energy and material is used in the construction process. The goal for construction is to become sustainable by reducing its impact on the environment through the construction of green buildings, utilizing sustainable materials, and employing energy efficiency. How are companies in the industry achieving these goals? Let’s take a look:

Green Buildings and LEED

Green buildings are buildings that have been constructed with respect to environmental sustainability. They first came about in the 1970’s, eventually gaining more popularity in the 90’s when the first Green Building Council was formed.

The generally accepted definition for a green building is “the planning, design, construction, and operations of a building with several crucial considerations: energy use, water use, indoor environment quality, material selection, and finally how the building affects its site.” One of the most direct ways that construction is sustainable is through LEED, the most widely used green building rating system in the world. The effectiveness of a green building is coded by the LEED Green Building Rating System.

Before LEED was established in the mid to late 90’s, there were green building projects, however there was no way to know if they were being implemented effectively. Nowadays, LEED will give out plaques to buildings which have been constructed to be sustainable. There are more than 60,000 buildings that participate in LEED today, occupying up to 1.7 million square feet.

Individuals throughout the industry can also earn a certification from LEED, which is exactly what one of our team members has done. D&B Construction’s Operations Manager, Jessica Nelis, obtained her LEED AP, ID+C (focused on interior design and construction) certification around 2010. Jess says, “I became a LEED accredited professional because I knew it would be important and relevant moving forward.” Jess provides a unique perspective on environmental consciousness that we take seriously here at D&B Construction.

Not only are green buildings environmentally friendly, it has been discovered that green buildings promote healthier living. Research shows that people who live or work in a green building experience proven psychological benefits. For example, in a green office building cognitive function scores rose by 61 percent. It is also reported that employees were 44 percent better at making decisions towards achieving workplace goals. In addition, at the Akron Children’s Hospital, 56 percent of people were satisfied with the cheerfulness of the hospital after its own green building renovations. There were also decreased reports of Seasonal Affective Disorder.

According to a report conducted by Grand View Research, the green building materials market has been a vital part of the construction industry’s green footprint, like Jess thought, and is expected to be worth $364.6 billion by 2022 (compared to an estimated $238 billion in 2020).

It’s clear to see why demand for the use of green materials has been a recent trend in the construction industry. Because of this demand, innovative green materials have become very popular.

Trending Sustainable Materials

Sustainable construction is achieved through using sustainable materials such as bamboo, eco-friendly insulation, and even smart glass windows.

If you want to be more sustainable, you could consider bamboo flooring for your project. Bamboo is a great alternative because it looks like wood but has a harvesting cycle of only three years, 22 years shorter than that of a tree. If you choose to use bamboo, you are helping to slow the rate of deforestation by allowing time for trees to grow back.

If insulation adequately cuts down on the energy used for heating and cooling, it could be sustainable. However, this can be counteracted if batts, fillers, and sprays that are not sustainable are used on the insulation. What is the eco-friendly option gaining popularity lately? Hemp insulation. It has all the same properties of normal insulation, but it is a sustainable option. Because it can be compressed, hemp can even provide more superior insulation than your typical insulation.

Another recent movement in sustainable construction is the use of smart glass windows. They were invented in the early 2000’s but have only recently become a building trend. Smart glass changes its heating properties based on the temperature outside, affecting how the heat and air conditioning is run through the building. During the hot summer months, a smart glass window will become translucent to block heating wavelengths that would allow you to run the air conditioning less and vice versa.

There are several options available if you wish to replace your windows with smart glass windows. These options vary in pricing and components of their smart glass technology. First, there are dynamic smart windows, produced by View Smart Windows. This is the “luxury” option, costing $50 to $100 per square foot, in comparison to a normal window which costs $10 to $15 per square foot. This high-end option replaces your normal windows and is even equipped with Wi-Fi control through their downloadable app.

A more cost-effective option is Invisishade’s self-adhesive and smart glass windows. Invisishade offers a “plug-and-play” adhesive film kit which transforms your normal window into smart glass. A sample of their self-adhesive film kit would cost $99, or $249 for a pack of three. The final price of their product varies on size and scope of the project, however Invisishade would offer a discount on bulk .

Smart Glass Windows may seem as if they are an expensive solution for sustainability due to its pricing when compared to normal glass windows. However, manufacturers claim that you can save up to 20% on your monthly energy costs because of their tinting properties. Smart glass allows you to save money on your monthly bills while also making the property look more aesthetically pleasing by eliminating the need for blinds.

Upcoming Trends: Self-mending Concrete

Be on the lookout for an emergence of living materials being used to complete green building projects in 2022. Living materials are biological compounds that grow and are ready to produce full-scale production. An example of a promising living material we have not seen much of yet is self-mending concrete. This concrete is full of bacteria that bind the materials around them into a new material form. This material can grow itself into the pores of concrete, essentially being able to rebuild the concrete on its own. The bacteria inside of this concrete can live for up to 200 years. Scientists say that in theory the bacteria would then be able to extend the concrete’s life for that long as well. Seeing as normal concrete lives for 50 to 70 years, this self-sustaining concrete would be much more useful in the long run. We have only begun to scrape the surface of possibilities for this self-mending concrete, but as we learn more it may prove to be a revolutionary material in construction.

New forms of concrete are a key component to sustainability since it is the second most used material on Earth, with only water exceeding it. One of the trends that will become increasingly popular is 3D printing with concrete. This year a 3D printed home community was constructed in Austin, Texas by ICON. It consisted of four homes, all listed on the market for $450,000. The company that built the houses used 3D printing technology to create the first floor of all four homes while the rest of the homes were built conventionally. Houses of this size can be constructed in just five to seven days. The homes were built using cement-based material LavaCrete, a material designed to cope with extreme weather. LavaCrete lived up to its claim when the houses withstood a 7.4 magnitude earthquake with no damages.

The Austin homes are not a unique case. There is also a 3D printed home community being built in Coachella, California. By 2022, this community is going to have 15 houses, each of which will be 1,450 square feet and feature three bedrooms, two bathrooms, a terrace, and a swimming pool. Sustainable real estate development group Palari and construction technology company Mighty Buildings will work together to complete the project.

The potential this unique industry has does not stop at high-end homes… nor does it stop on this planet. ICON, the same company that built the Austin, Texas community of 3D printed homes, is currently working in the research and development phase with NASA to create a space-based construction system. Their goal is to construct 3D printed buildings on the Moon and Mars.

The industry has already evolved as people are beginning to purchase and live in 3D printed homes. Meet a previously homeless Texas man who became one of America’s first inhabitants of a 3D printed home. The best thing about 3D printed concrete for homes is that it is environmentally friendly. This form of building uses the exact amount of material needed to complete the project, allowing for less materials like concrete to be used to construct the building, therefore benefitting the environment.

The potential that 3D printing concrete has is immense and is something worth following as they make progress over the next few years. Stay up to date with 3D printing news here.

Concrete is the second most used material on Earth, trailing only water. Because of this and our commitment to safety, we find it important to highlight concrete safety tips. Here are some vital practices that every company should follow to stay safe when working with concrete:

Use Proper PPE To Protect Yourself

PPE is one of the most important elements of safety on any jobsite, but it is especially important when you are working with concrete. Make sure to protect your skin at all times by wearing gloves. Water-proof and alkali-resistant gloves are recommended. A long-sleeved shirt, full-length pants, and shatterproof eye protection are also important when working with wet concrete. If you are standing in the wet concrete, wear water-proof boots that are up high enough on your ankle so that the concrete cannot flow into your shoes. You will also want to always wear a hard hat, especially when pouring concrete in an interior area where the ceiling is not yet complete. Proper ear protection, proper footwear, and face masks or ventilators are also important PPE.

Take Care When Removing Concrete PPE

Be careful when removing concrete PPE, as wet cement could get on your skin. Did you know that wet cement is the #1 cause of occupational skin disease in the United States? To learn more, watch this video, which includes additional concrete safety tips. Concrete burns are a serious and common injury when working with concrete. It is important to always be aware that concrete can find its way into your personal equipment such as gloves, boots and sleeves. To avoid getting burned, remove any clothing splattered in concrete and wash the affected area immediately, not in the next hour. You will then want to keep an eye on your skin to see if a burn is developing. Be careful when you are removing your protective clothing and wash your hands before and after. You should also store your concrete-soiled clothes separately from other clothes and tools. If possible, shower before leaving the jobsite so you can change into new clothes. This will decrease your exposure to crystalline silica, which we discuss more in depth below:

The Dangers of Crystalline Silica

Crystalline silica are very small particles, nearly 100 times smaller than the sand we find on beaches. These particles are present in concrete and other building materials. Even with proper safety precautions, workers who are exposed to crystalline silica may still inhale the dangerous particles.

To be safe, warn workers and mark boundaries of work areas with crystalline silica. It is a best practice to do this because when large amounts of crystalline silica are inhaled, workers are at risk of developing a long-term lung disease known as silicosis. Silicosis can be fatal. The CDC reports that 1,167 people died from silicosis from 2005-2014. Make sure to educate your workers about the risks and harm of crystalline silica by providing proper training that includes information about health effects, work practices, and protective equipment for respirable crystalline silica. You can also learn more about the standards OSHA requires here.

In addition to educating and training your workers about crystalline silica, you should also provide those exposed to crystalline silica with periodic medical examination. One of the best ways to prevent the inhalation of crystalline silica is to keep dust out of the air. When you are purchasing equipment look to see if there is a dust control, make sure to always maintain and use the dust control system, and if the dust control system is not working do not use the equipment. Using the nearby exhaust ventilation system can help to keep dust from being released into the air. When you are sawing concrete, you can use a saw that provides water to the blade, as this will make the dust particles wet and prevent it from being released into the air.

To learn more about preventing the inhalation of crystalline silica watch this video.

Some Items Should Be Avoided When Working With Concrete

When working with concrete, steer clear of using tobacco products in dusty areas. BioMed Central did a report in 2018 that found silica-exposed smokers had elevated mortality from non-malignant respiratory disease and lung cancers in comparison to non-smokers. The use of tobacco in dusty areas may leave you more likely to inhale crystalline silica. To proactively prevent the inhalation of crystalline silica you should do air monitoring to measure worker’s exposure to crystalline silica, as well as to select appropriate engineering controls and respiratory protection. You should perform air monitoring to measure the effectiveness of controls, collecting and analyzing air samples according to the National Institute for Occupational Safety and Health Method Nos. 7500 and 7602.

White-sand beaches, warm weather, great food, and high-end luxuries are everything that Miami is known for. The small town of Surfside is no exception with its reputation of being pleasant, quiet, safe, and affordable. As you likely may have heard, Surfside recently become the center of attention for many people after tragedy struck the small town in June.

On June 24th Surfside’s 12-story beachfront condo, Champlain Towers South, partially collapsed at about 1:25 AM with its residents inside. As of Monday, July 26th, the last victim’s remains were identified. This brought the final death toll to 98 people after tedious efforts were made to account for every resident, and officials have now confirmed that remains for each person considered missing after the collapse have been recovered. The efforts made were the largest emergency unrelated to hurricanes ever conducted in the state, with search and rescue teams from throughout Florida, many other states, and even Israel and Mexico coming together to bring closure to families.

According to the New York Times, this disaster is one of the deadliest structural building failures in American History. Many residents are still in shock. Community Members Peggy Streter and her husband own The Carrot Café located in downtown Surfside. The two have claimed to know about 50 people who lived in the condo. The Streters are not the exception. Miami’s building chief, Charles Danger said, “Everybody in Miami knows somebody from that building or knows somebody who knows somebody.”

The rest of the building was demolished on Sunday, July 4th in efforts to continue the search. Once all remains were identified of those missing, officials began steering their focus to determining what could have caused the collapse. Since then the building has continued to be in the limelight, as many of the building’s records that would help investigators learn why the building fell could not be found, and the not-so-easy conversation over the fate of the site has started to take place. Here’s a quick summary of what is known:

Initial Concerns for the Condo

People living in Surfside Condos, which were completed in 1981, had previously voiced their concerns about the structure of the building they called home, so the collapse does not come as a surprise for some. After a DEA building collapsed in Miami almost half a century ago, taking the lives of seven employees and injuring 16 others, two Miami counties instilled new regulations requiring buildings that have stood for 40 years to be investigated for any problems. Since Champlain Towers South was in one of these counties, their mandatory 40-year inspection took place in 2018.

When the condo was inspected by engineer Frank Morabito in 2018, he identified that there was a flaw in the original construction of the building that was causing structural damage. Morabito mentioned the main issue was that the pool deck and outdoor planters had been “laid on a flat structure.” Since there was no slope where the pool stood, standing water was not able to drain off the pool deck. Instead, the water would sit on the waterproofed concrete until it evaporated. At the time of inspection, the water-proofing concrete had failed, causing the water to seep through resulting in “major structural damage to the concrete slab below these areas.” The report also pointed out distress and fatigue in the concrete, columns, beams, and walls of the parking garage below the pool area.

Morabito’s report said that “failure to replace the waterproofing in the near future will cause the extent of the concrete deterioration to expand exponentially.” He could not predict that this may lead to the collapse of the building, however he said that repairs to the concrete were needed for “maintaining the structural integrity” of the building. The waterproofing and structural issues of the condo were never addressed by the owner’s association.

Fast forward to 2019 when a neighboring luxury tower was being built. Residents of the Champlain Towers South condominium complained that construction would often cause their building to shake. This led to a resident and board member of the condo association, Mara Chouela, voicing her opinion that workers were “digging too close” to the property. She said they “have concerns regarding the structure of our building.” Just 28 minutes later, official Rosendo Prieto responded to Chouela stating that “there is nothing for me to check.”

There is no concrete evidence that construction of the condo’s neighbor contributed to the collapse of the building, and it is still unclear if the lack of action from the owner’s association was a major factor in the building’s collapse. Cassie Stratton, a resident who was inside the building during the collapse, reportedly told her husband on the phone that she saw the pool cave in first, backing up Morabito’s claim that the waterproofing of the pool was necessary to maintain the structure of the building.

The fact remains that residents were concerned for the structure of the condo, and they felt as if no one took the necessary action to redeem the structural integrity of the building.

Expert’s Findings

The city of Surfside hired a structural engineer, Allyn Kilsheimer, to inspect the site and determine the cause for the buildings collapse. Kilsheimer says it is “maybe not an individual cause, but two or three things that contributed and/or caused this failure.” While the pool could have been a major issue to the structural problems, it is still unclear and there are many theories that will be examined.

In addition to hiring Kilsheimer, another group was hired to lead the charge to uncover what caused the collapse since this was such a big case. The NIST (National Institute of Standards and Technology) will be working constantly to investigate the situation. They say that “a fact-finding investigation of the building performance and emergency response and evacuation procedures will likely result in significant and new knowledge or building code revision recommendations needed to reduce or mitigate public risk and economic losses from future building failures.”

How this Tragedy may Impact the Industry

Like many others, we have been wondering what caused this to happen. Matt Knight, Senior Estimator at D&B Construction, has been working in the industry for over 20 years. He has been involved with the construction of many large, well-known buildings, including the 9/11 Memorial.

Matt did not do any research, but from what he saw “the building collapsed from the bottom up,” which makes him think “there would be structural cracks in the floor, columns, beams, etc.” As we know now, these structural cracks were found by engineers and deemed to be a major structural concern prior to the collapse of the building. Much like Allyn Kilsheimer, Matt believes that it is likely there are multiple causes for the failure of Champlain Towers South.

One of the theories that Matt believes had a big role in the building’s collapse was the fact that the condo had been sinking at a rate of two millimeters per year from 1993 to 1999. Scientists also discovered evidence of other areas nearby sinking as well. Matt says that one of the most important things when constructing large buildings is to make sure you are building on good soil. Since the condo was slowly sinking, Matt believes they likely “built on unsuitable soils and never got the compaction they needed.” He notes that if soil is not properly compacted so that it is suitable for the building, everything else will eventually fail. “If you are building from the ground up your soil underneath is, of course, most important,” he concludes. For now, Matt is waiting to learn more about what caused the failure once the investigations are conclusive.

What we can Conclude and How to Move Forward

At the end of the day, the collapse of Champlain Towers South was a tragedy, however Matt tries to look at how the industry as a whole can learn from what happened. “Usually a lot of good things will come out of a catastrophic failure. For example, we learned a lot from 9/11, and today those World Trade Center Towers are not being built the same way,” he says. Matt believes the industry will learn valuable lessons from this, and it will improve how we are constructing buildings overall. He would not be surprised if there will be changes for older building’s codes, especially around that area. Matt also proposes the idea of a new law emerging from this that would make building owners, when aware of structural damages, either make the repairs or move everyone out until they do.

While we wait to learn more, one question many still have is whether or not limitations on technology when the condo was built play a factor in the failure of Champlain Towers South? When the condo building was constructed in 1981 many of the rules and regulations that we have today were not in place. Miami was also known for “slipshod construction,” and in some cases they were known to take the look-the-other-way approach when enforcing building codes and regulations. While their construction practices were not nearly as good then as they are now, they also did not have access to the technology we have now.

Specifically, VDC (Virtual Design and Construction) and BIM (Building Information Modeling) are tools that Matt says, “could have helped if they had it during original construction”. BIM is a tool for 3D modeling and data input of physical objects, while VDC uses BIM models to plan the construction process from beginning to end. Watch a video to learn more about VDC and BIM here. Using technology like BIM and VDC essentially allows you to build the entire project virtually before building it in the real world, which can decrease cost and time put into a project while also increasing safety. We may often take technology like this for granted, but it is interesting to think about what the world of construction would have looked like in the 80’s if society had access to these technologies that we can now use every day.

D&B is interested to hear your thoughts. Do you think new technologies will help to prevent disasters like the one in Surfside? What policies and procedures do you think should be put into place to help increase safety and avoid disasters such as this from happening in the future? Let us know in the comments below!

Trend 1: LEED and Green Building

“A ‘Green’ building is a building that, in its design, construction or operation, reduces or eliminates negative impacts, and can create positive impacts, on our climate and natural environment. Green buildings preserve precious natural resources and improve our quality of life” (WGBC). In response to the COVID-19 pandemic, Green or LEED construction is changing. The U.S. Green Building Council, creators of the LEED certification, plans to promote healthier and safer air quality indoors with adjusted certification criteria incentivizing the creation cleaner air systems. In 2021, there will be more building materials and components that help get LEED certification. One interesting and somewhat new development is a form of self-healing bio-concrete. This is a compound of concrete and bacteria that produces limestone when exposed to air and water, which helps with the impermeability of the surface. It costs around $240 per cubic meter. For reference, normal concrete usually costs between $200-$300, making it still cost efficient. Green building will continue to grow throughout the next decades and new technology and policy will come out to reinforce it as time goes by.

Trend 2: Modular Construction

The construction industry is rapidly moving towards modular materials because of its cost and time efficiency. Modular building is anywhere from 20% – 50% faster than traditional construction. It is also around 20% more cost efficient to build modular instead of traditional because of the reduced labor and time costs. Modular building also cuts the waste output almost in half due to optimal fabrication and pre-planned units. Everything is built off the construction site, which reduces the challenges of regular construction such as weather, limited working hours, and space. Overall, modular building is great for symmetrical and repeating buildings where sections can be made and stacked or attached to each other easily like in apartment or office buildings.

Trend 3: Safety

As it should be, safety is a huge trend in 2021. The old workplace safety system focused on recognizing problems and fixing them after someone gets hurt or a problem occurs. The new system getting pushed in the industry is based on prevention through education and training and recognizing issues before anyone gets hurt. This is why we have our Safety Committee meet monthly to discuss different topics of safety. Another large change in the safety category is better technology with Personal Protection Equipment (PPE). With more women entering the field, there is an increased awareness of the need for PPE to properly fit all employees to ensure safety. In addition, because of the COVID-19 pandemic there are policies across most companies including D&B that promote safe environments using masks, social distancing, and sanitization. When the pandemic hit, our team implemented a sign in and sign out sheet at every job site, making it easy for us to accurately perform contact tracing in the event that someone developed COVID-19 symptoms. D&B will continue to enforce this rule across all job sites moving forward. Learn more about our safety standards here.

Trend 4: Multi-Family

Multi-family construction is one of the fastest growing sectors of the commercial construction industry. Because of the lack of inventory in the housing market and changing demographics, multi-family construction is in high demand and will continue to grow in the following years. More people are looking for smaller, more affordable homes and condominiums with less maintenance than a normal single-family house. Research shows that 33% of people who are reaching age 55 are on their own. This is much different than what was the case 20 years ago. Currently D&B has multiple multi-family jobs under active construction and in the pre-construction phases. Throughout my internship, I shadowed the construction of The Reserve at Gring’s Mill, which you can view here.

Written by: D&B Intern, Alex Wolf

Alex culminated this list based on what he learned during his time at D&B. He is a Senior at Wilson High School who began shadowing various D&B employees in September of 2020. Alex will be attending Virginia Tech for Architecture in the Fall. “My internship experience at D&B made me realize that I want to pursue a career in residential remodeling and construction,” he explains. “I gained a lot of knowledge about the construction process and enjoyed being able to see entire construction projects from start to finish.”

On February 22, 2021, we celebrated our 10 year anniversary! This milestone is something to celebrate. According to historical data from the Bureau of Labor Statistics, the construction industry has one of the lowest business survival rates. About 25% of small construction companies don’t survive their first year, and labor statistics also show that 70% of these businesses never make it to their 10th anniversary.

From flipping homes and completing renovations, to building entire custom homes from the ground up, to entering the commercial construction industry and completing over 5 million SF since then… A lot has happened in the last decade. We owe it all to our amazing team members, trade partners, suppliers, clients, friends and family! Thank you for being part of this journey, and we look forward to what’s to come in the next decade!

Reflecting on 10 Years

Q: Any fun memories or stories that you’d like to share?

“When I first started at D&B we were much smaller, with offices across the hall. I was excited to work for Al, Dan and Brennan because there was an underlying positive energy that was contagious. I remember Brennan bouncing his ball against a wall when he would visit our side, driving us all crazy, and Dan running through the office saying “coming through”. When Tom started we made him a make shift desk in the copy room. It was a little rough and we made it work. If you ever need anything go to Adam, he is our historian and remembers everything! We have grown so much in the five years I have been here, and it has been fun being part of that growth both personally and professionally. I work with the best team! They happily share their knowledge, teach me something every day and challenge me to grow. They are my extended family. I also want to thank Al, Dan and Brennan for giving me an opportunity to be a part of a great team!”

-Beth, Project Coordinator

“When I first started we were limited on office space at the Park Road office. I was sharing an office with three other team members. Within a week, I adapted and found a corner in the room where the printer was. I made a desk from cardboard boxes and an old countertop. Talk about improvising. It actually worked well. HA!”

-Tom, Construction Manager & Safety Director

“I remember the first time I met Dan & Brennan when they first got started 10 years ago. I was on the other side of the job as an inspector for Lower Heidelberg Township. I believe they were constructing a deck, sunroom or an addition somewhere in the Green Valley area. I came across a lot of contractors in my 13 years as a building inspector, but always remembered them from the first meeting. Great guys with a goal of doing it the right way! This 10-year anniversary is a testament to them honoring their commitment to doing things the right way for their clients, employees and themselves!”

-Andrew, Assistant Project Manager

Q: How have you personally grown since first starting at D&B? What have you learned?

“The importance of teamwork. D&B has shown me what can be accomplished when there is a team that will support you from top to bottom.”

-Matt, Project Manager

“I have grown my leadership skills tremendously, and I learned that I can actually make a difference.”

-Tom, Construction Manager & Safety Director

“I’ve been here since January of this year, but I feel like it’s been much longer. The team has accepted me, and I love the company culture. I have learned a ton about our processes, software and my teammates. The ‘go-getter’ attitude of our leaders has me extremely excited for the future!”

-Andrew, Assistant Project Manager

Q: How have Dan and Brennan evolved as leaders since you began?

“They are evolving into awesome leaders. The growth that the joint venture of Metro and D&B bring are endless. They always have and always will have each other to bounce ideas off of. Not one decision is made for the company without them both discussing it together.”

-Alex, Superintendent

“Dan and Brennan are growing as leaders since I started and will continue to grow with the company.”

-Tom, Vice President of Construction for the Reading Division

Q: When you think of your D&B family what is the first thing that comes to mind?

“Teamwork. A commitment to excellence and doing things the right way for the client.”

-Andrew, Assistant Project Manager

“Compassion and understanding.”

-Matt, Project Manager

“Unbelievable teamwork and teammates.”

-Alex, Superintendent

“Teamwork.”

-Tom, Construction Manager & Safety Director

“Cooperation.”

-Barry, Superintendent

Q: Anything you want to say to the D&B team as a whole?

“Keep up the good work and adapt with the growth.”

-Tom, Vice President of Construction for the Reading Division

“I would like to say thanks to everyone. Many people in the company reached out to me when my mother passed, and it means more to me than they know.”

-Matt, Project Manager

“Being a part of this team makes me feel so proud. It’s a breath of fresh air knowing I can rely on our team for help or ideas. As long as we stick together and use all of our teammates, there is nothing we can’t do!”

-Alex, Superintendent

Q: How would you define our company culture in a few words?

“Teamwork. Cohesive. Fun!”

-Andrew, Assistant Project Manager

“Engaging, welcoming, team oriented, rewarding, flexible, motivating and connected.”

-Alex, Superintendent

“Teamwork and striving for excellence.”

-Matt, Project Manager

“The culture here is unique compared to other companies.”

-Tom, Vice President of Construction for the Reading Division

Q: What do you love most about working at D&B?

“The challenge to keep up.”

-Barry, Superintendent

“Everyone has been extremely helpful in bringing me up to speed and getting me involved in as much as possible. The work atmosphere is fun, all while getting the tasks accomplished in timely manner. It is a great team with great balance across all facets.”

-Andrew, Assistant Project Manager

“The people. Everyone is down to earth and is there to support whenever possible. In times of need, D&B employees have been there to lend a helping hand or provide insight on an issue on a project.”

-Matt, Project Manager

“Mentoring the younger team members and watching them grow.”

-Tom, Vice President of Construction for the Reading Division

Learn More About D&B

If you follow our social media, you’ve likely seen our YouTube series reflecting on 10 years to celebrate the company’s milestone. Catch each episode here:

Episode 1: Dan and Brennan, and their wives, Urs and Jenny, reflect on the many different office spaces we’ve had throughout the last decade. Learn more about how we went from an office space in a house Dan and Brennan ended up flipping to where we are today.

Episode 2: Dan and Brennan discuss how D&B has grown in the last 10 years and whether or not they expected to be where they are now.

Episode 3: Did you know that Dan and Brennan were teammates long before they started the company? They played soccer together at Elizabethtown College (where they were also roommates). Learn how they have grown over the years and how their partnership complements one another.

Episode 4: This episode focuses on our most important asset – our team! In the words of Dan and Brennan, “Our team is what got us here today.” Dan, Brennan, and their wives recognize and celebrate everyone who makes up the D&B family.

Episode 5: Dan and Brennan’s family send their congratulations to Team D&B on their 10 year anniversary. Plus, you’ll learn what some of the D&B kids love most about visiting their dads and the team at the office.