Cold weather is upon us as we gear up for another Winter season. It is crucial that all workers in the industry are prepared to work in these cold weather conditions. We prepared Team D&B for the cold months ahead at the start of December during our monthly Safety Meeting. Our Superintendent, Jason, presented a Tool Box Talk on Cold Weather Considerations. Since safety is our standard we wanted to share some of the pointers our team discussed during our latest Safety Meeting:

-Wearing several layers of clothing is always more beneficial than wearing one thick layer when working in cold weather.

-Did you know that forty percent of a person’s body heat can be lost from an uncovered head?! Because of this, wearing a warm wool hat or a helmet liner under your hard hat is always a good idea. Be sure to cover your ears and remember to wear gloves, too!

-When it comes to footwear, wear one or two pairs of warm socks. Your footwear should not fit too tightly or it will restrict blood flow and ultimately cause more harm than good.

-In cold, windy weather it is a good idea to wear a face mask or scarf.

-You need energy to keep your muscles warm, making it important to avoid exhaustion and fatigue. Take frequent short breaks in a warm shelter so your body has time to warm up and relax.

-Drink warm, sweet beverages and avoid drinks with caffeine. Eat warm, high calorie food such as pasta dishes for lunch.

Tom Rinaldo, our Safety Director and Vice President of Construction for Reading and Central PA, also provided us with some helpful insight to common questions people tend to have regarding cold weather safety:

Q: What are some ways you keep warm when working outside in the cold?

A: “Proper attire during the cold weather months is a definite must. You definitely want to have proper socks and footwear. Keeping perspiration away from the skin is a big one. You want socks that wick sweat and perspiration. Wearing synthetic or cotton clothing next to your skin is the best way to wick away any sweat. If you keep that sweat away from your body, you won’t get as cold. The reason people’s feet get cold is from sweating, which happens even in the winter – especially when working on a construction site. The body can lose up to 85% of its heat through sweating during exercise. I recommend purchasing socks that wick the sweat away from your feet to help you stay a lot warmer. There are several different brands available. I believe Under Armour makes them, and Wick Dry CoolMax by Fox River is another go to brand.”

Q: What different kinds of foods do you eat/drink in the winter to keep you warmer?

A: “You always need to stay hydrated. People don’t realize this, but even though it is Winter you still need to drink plenty of water to stay hydrated. You will see me with a thermos of hot soup for lunch instead of a cold sandwich in the winter time.”

Q: Do you make sure you go somewhere warm for breaks in the colder weather? If so, where do you suggest?

A: “We usually tell the guys to go into their vehicles if they are out on an open construction site. If they are on an interior construction site there is usually heat on. At our job sites, we also have temporary heaters on. These are not only to keep the worker’s warm, but also for the product we are putting in. Once you get to drywall you have to condition the space.”

Q: What are some clothing layering methods you use?

A: “A very important factor is keeping the wind off you. When you layer your clothing your cutting the wind out from getting to your body. Having the proper gear, such as boots, gloves, and a hat are very important. Last month we got a new order of hats so our Team has them to put under their hard hat when on the job site.”

Tom usually wears three layers under his winter coat: A t-shirt, a long sleeve t-shirt, and a hoodie. He also wears long underwear, wicking Under Armour shirt, and Under Armour bottoms.

Q: What are some ways that a Site Superintendent can help the men and women on their job sites stay warm?

A: “Making sure they have the proper attire and making sure they are taking the proper number of breaks, especially when the temperatures get below 20 degrees. We typically have two 15-minute breaks throughout the day, one in the morning and another in the afternoon, in addition to a lunch break. At D&B, we always educate our team on hypothermia at safety meetings and in our safety training. We know that one of the main injuries, according to OSHA, would be slips and falls. This, along with hypothermia, frostbite, ice, cold stress, and winter colds and flus are common winter hazards that we educate the team on.”

Q: What do you recommend someone new to working in the cold weather prepares for?

A: “It is important that they make sure they have the right clothes. They may not be used to spending eight hours out on a construction site, so it is important that they have the proper gear for the elements.

Q: Are there any common misconceptions that people think are helpful in the cold, but are harmful?

A: “Coffee might warm you up for a few seconds, but since it contains caffeine it can increase your urination frequency and ultimately dehydrate you. Make sure you drink it in moderation to avoid this.”

Q: Anything else you want to add?

A: “You have to know when your body is telling you to get away from the cold environment. Realizing the signs of cold stress, hypothermia, frostbite, etc. are important. Listen to your body. It will tell you when to stop doing what you’re doing.”

Frostbite and Hypothermia: Two Serious Conditions That May Result from Prolonged Exposure to the Cold

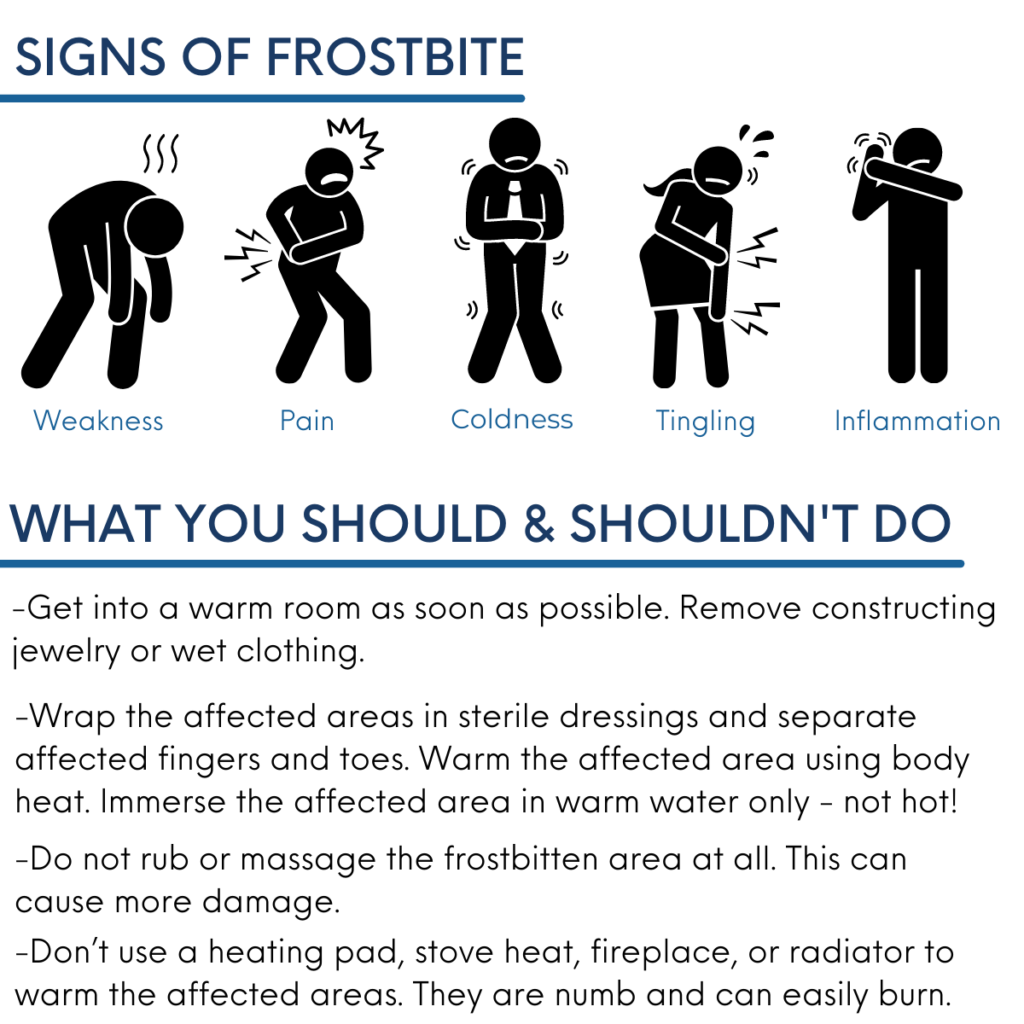

Frostbite is an injury to the skin and underlying tissue. Most often it is found on a person’s nose, ears, fingers, or toes. One of the first symptoms are a “pins and needles” sensation followed by numbness or pain in the affected extremities. Hard, pale, and cold skin is a way of distinguishing frostbite. Once the area thaws, the flesh becomes red and very painful.

Below is an infographic illustrating signs of frostbite and some pointers on what you should and shouldn’t do if you or someone on your job site is affected:

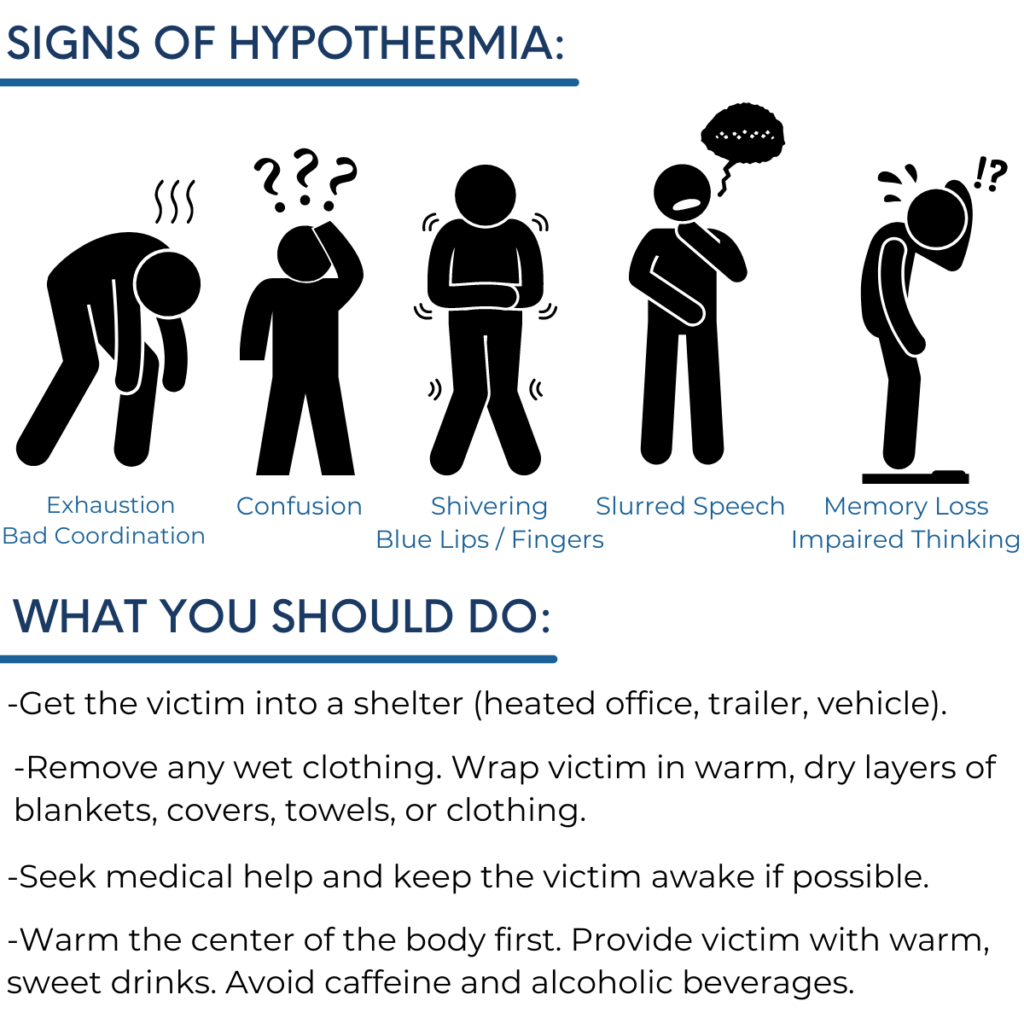

Hypothermia is a medical condition in which the person’s core body temperature drops significantly below normal and normal metabolism begins to be impaired. This occurs when the core temperature drops below 95 °F (35 °C). If body temperature falls below 90 °F (32 °C) the condition can become critical and eventually fatal. It is important to note that Hypothermia can still occur at temperatures well above freezing when a victim is submerged in cold water.

Below is an infographic illustrating signs of hypothermia and some pointers on what you should and shouldn’t do if you or someone on your job site is affected:

Consider printing out OSHA’s Cold Stress Card in both English and Spanish to have on the jobsite for all workers safety. These cards include information on common types of cold stress, such as hypothermia, frostbite, and trench foot (also known as Immersion Foot), as well as ways to prevent it and treat it.

We hope you find this article helpful as you and your team brave the cold winter months! If you have any additional tips, we’d love for you to share in the comments below.

Concrete is the second most used material on Earth, trailing only water. Because of this and our commitment to safety, we find it important to highlight concrete safety tips. Here are some vital practices that every company should follow to stay safe when working with concrete:

Use Proper PPE To Protect Yourself

PPE is one of the most important elements of safety on any jobsite, but it is especially important when you are working with concrete. Make sure to protect your skin at all times by wearing gloves. Water-proof and alkali-resistant gloves are recommended. A long-sleeved shirt, full-length pants, and shatterproof eye protection are also important when working with wet concrete. If you are standing in the wet concrete, wear water-proof boots that are up high enough on your ankle so that the concrete cannot flow into your shoes. You will also want to always wear a hard hat, especially when pouring concrete in an interior area where the ceiling is not yet complete. Proper ear protection, proper footwear, and face masks or ventilators are also important PPE.

Take Care When Removing Concrete PPE

Be careful when removing concrete PPE, as wet cement could get on your skin. Did you know that wet cement is the #1 cause of occupational skin disease in the United States? To learn more, watch this video, which includes additional concrete safety tips. Concrete burns are a serious and common injury when working with concrete. It is important to always be aware that concrete can find its way into your personal equipment such as gloves, boots and sleeves. To avoid getting burned, remove any clothing splattered in concrete and wash the affected area immediately, not in the next hour. You will then want to keep an eye on your skin to see if a burn is developing. Be careful when you are removing your protective clothing and wash your hands before and after. You should also store your concrete-soiled clothes separately from other clothes and tools. If possible, shower before leaving the jobsite so you can change into new clothes. This will decrease your exposure to crystalline silica, which we discuss more in depth below:

The Dangers of Crystalline Silica

Crystalline silica are very small particles, nearly 100 times smaller than the sand we find on beaches. These particles are present in concrete and other building materials. Even with proper safety precautions, workers who are exposed to crystalline silica may still inhale the dangerous particles.

To be safe, warn workers and mark boundaries of work areas with crystalline silica. It is a best practice to do this because when large amounts of crystalline silica are inhaled, workers are at risk of developing a long-term lung disease known as silicosis. Silicosis can be fatal. The CDC reports that 1,167 people died from silicosis from 2005-2014. Make sure to educate your workers about the risks and harm of crystalline silica by providing proper training that includes information about health effects, work practices, and protective equipment for respirable crystalline silica. You can also learn more about the standards OSHA requires here.

In addition to educating and training your workers about crystalline silica, you should also provide those exposed to crystalline silica with periodic medical examination. One of the best ways to prevent the inhalation of crystalline silica is to keep dust out of the air. When you are purchasing equipment look to see if there is a dust control, make sure to always maintain and use the dust control system, and if the dust control system is not working do not use the equipment. Using the nearby exhaust ventilation system can help to keep dust from being released into the air. When you are sawing concrete, you can use a saw that provides water to the blade, as this will make the dust particles wet and prevent it from being released into the air.

To learn more about preventing the inhalation of crystalline silica watch this video.

Some Items Should Be Avoided When Working With Concrete

When working with concrete, steer clear of using tobacco products in dusty areas. BioMed Central did a report in 2018 that found silica-exposed smokers had elevated mortality from non-malignant respiratory disease and lung cancers in comparison to non-smokers. The use of tobacco in dusty areas may leave you more likely to inhale crystalline silica. To proactively prevent the inhalation of crystalline silica you should do air monitoring to measure worker’s exposure to crystalline silica, as well as to select appropriate engineering controls and respiratory protection. You should perform air monitoring to measure the effectiveness of controls, collecting and analyzing air samples according to the National Institute for Occupational Safety and Health Method Nos. 7500 and 7602.

Safe + Sound is a year-round campaign to encourage every workplace to have a safety and health program. It was launched by OSHA in an effort to gain safety awareness. Every year in August, OSHA has a Safe + Sound week, with this year’s taking place from Monday, August 9th to Sunday, August 15th.

This nationwide event recognizes the success of workplace health and safety programs and offers information and ideas on how to keep America’s workers safe. Seven businesses make up the list of organizers who participate in planning calls, working collaboratively with each other to develop and review Safe + Sound materials and communications, and leverage their own resources to support these efforts. In addition to OSHA, these businesses include large organizations, such as the National Safety Council and . The program also has 225 partners who are membership organizations that are responsible for communication and outreach throughout the year to promote Safe + Sound to their stakeholders.

D&B Construction is one of 68 companies throughout PA (and over 1,600 across the nation) who have signed up to participate in Safe + Sound Week 2021. We are excited to show our support and commitment to continue building safer jobsites. People come first at D&B. The safety of our employees, trade partners, and clients is always paramount in every project’s preparation and execution. In order to make this happen, safety and health are at the core of everything we do. Learn how here.

The Occupational Safety and Health Administration, better known as OSHA, was created in 1970 to ensure safe and healthy working conditions by setting and enforcing safety standards in addition to providing training, outreach, education, and assistance. You may have heard OSHA refer to the “Fatal Four” when describing the four most common causes of worker deaths on construction sites throughout the United States.

The four most common causes of worker deaths in this industry come from Falls,) which account for 33.5% of construction worker deaths), being struck by an object (11.1%), electrocutions (8.5%) and being caught in / between something accounted for 5.5% of construction worker deaths. According to OSHA, as of 2020 “one in five worker deaths in 2019 were in construction.” The “Fatal Four” were responsible for more than half (58.6%) of construction worker deaths. According to OSHA, if these “Fatal Four” causes could be eliminated, they would save 591 workers’ lives in America each year.

In 2020, OSHA gathered data on the top 10 instances of safety code violations. Learn what they are below, and hear from our Director of Construction and Safety Director, Tom, on how such issues can be avoided and prevented:

1. Inadequate Fall Prevention – 6,010 violations

What This Means: OSHA states that a violation could include not providing working conditions that are free of known dangers, failure to keep floors in work areas in a clean and dry state, as well as not providing required personal protective equipment at no cost to workers.

Tips on How to Prevent This: Our Safety Director, Tom, encourages the use of safety rails and body harnesses on every job site. “At D&B we provide these on every job site to give our workers the safest environmental possible.”

2. Inadequate Hazard Communication – 3,671 violations

What This Means: Simply put, this refers to the failure to inform all people on the job site of potential risks and hazards.

Tips on How to Prevent This: “At D&B we fill out a Job Safety Analysis (JSA) and Job Hazard Analysis (JHA) on all job sites,” explains Tom. “This helps us to ensure that we are communicating this vital information with all of our employees and trade partners. Communication is huge in enhancing safety.”

3. Unsafe Scaffolding – 2,813 violations

What This Means: Failure to abide to OSHA standards would include improper fall protection / fall arrest systems, unsuitable guardrail height, inadequate footing support, failure to complete inspections, etc.

Tips on How to Prevent This: Work with reputable scaffolding companies that you trust. “At D&B we complete daily and weekly inspections on the scaffolding on our site to ensure we are practicing proper scaffolding safety protocols,” says Tom.

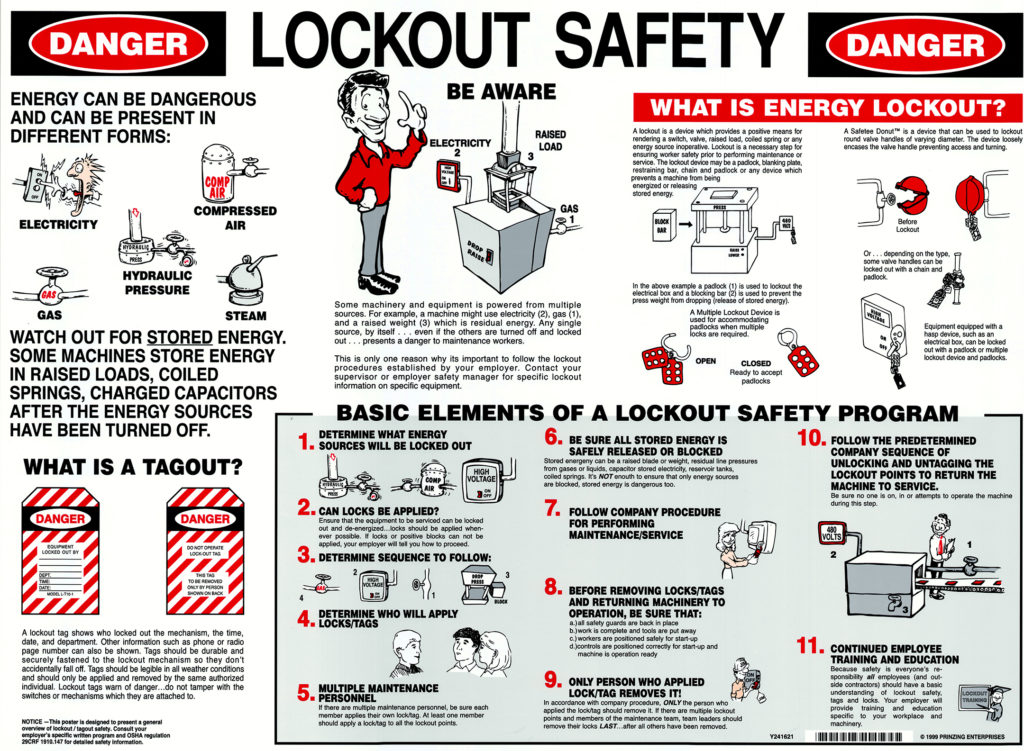

4. Failure to control hazardous energy (Lockout / Tagout Violations) – 2,606 violations

What This Means: Failure to address the practices and procedures needed to disable machinery or equipment that may expose workers to hazardous energy.

Tips on How to Prevent This: “There is no better way to ensure this mishap is avoided then by requiring all electricians on your job site to use lockout and tagout procedures on all powered equipment and panel boxes,” says Tom.

At D&B, we include the following lockout safety poster on our Safety Board at all jobsites:

5. Inadequate Respiratory Protection – 2,450 violations

What This Means: A violation would include not providing the proper respiratory protection.

Tips on How to Prevent This: “In addition to providing dust masks to all employees, it is important to utilize clean air machines and air scrubbers such as HEPA filters on your job sites,” says Tom. “In any situation where there are environmental hazards present, we as a company will hire a reputable remediation company to ensure the safety and health of all people on the job site. I highly recommend doing this when the elements require it.”

6. Unsafe Ladders – 2,345 violations

What This Means: This could include placing a ladder on a box or barrel, using ladders where there is unstable footing or soft ground, exceeding a ladder’s maximum load rating, ignoring nearby overhead power lines, moving or shifting the ladder while a person or equipment is on it, using an extension ladder horizontally as a platform, etc.

Tips on How to Prevent This: “Have your Site Superintendents check ladders on a daily and weekly basis. If any ladders are deemed unsafe or defective, they should be removed immediately,” says Tom. Unlike hard hats, for example, there is no specific expiration date for ladders. Following proper storage techniques and treating ladders with care can help in making them last longer.

7. Powered Industrial Truck Safety Violations – 2,093 violations

What This Means: This refers to improper vehicle use, lack of training, and a failure to re-certify operators every three years as required.

Tips on How to Prevent This: ” At D&B, we make sure all of our Pettibone and Lift operators are certified, and we require lift plans for any kind of crane lifts. This is something I recommend everyone get in the habit of making a standard practice.”

8. Inadequate Fall Prevention & Training Requirements – 1,773 violations

What This Means: Failure to provide proper fall prevention training is something that can easily be avoided if proper training and communication on fall prevention is completed on all job sites.

Tips on How to Prevent This: “All D&B Construction field personnel are OSHA certified, and we also hold training sessions throughout the course of the year,” explains Tom.

At D&B, we include the following fall protection poster on our Safety Board at all jobsites. This is an easy way to remind everyone on the job site of how to best prevent falls.

9. Unsafe Machinery and Inadequate Machine Guarding – 1,743 violations

What This Means: Failure to provide one or more methods of machine guarding to ensure the safety of the operator and others in the nearby area can result in an unsafe job site.

Tips on How to Prevent This: “All powered tools are inspected for proper and adequate guarding by a D&B employee, such as the Site Superintendent, before use,” says Tom.

10. Inadequate Personal Protective and Lifesaving Equipment, Eye and Face Protection – 1,411 violations

What This Means: Failure to make the appropriate personal protective equipment available to all employees at no cost is something that should not occur anywhere.

Tips on How to Prevent This: “Keep inventory of safety equipment, such as safety glasses and hi-visibility vests, for all of your employees. At D&B, we keep a document that is updated every time a new hire starts so we know the date in which they received all of their issued PPE. This makes it easy for us to keep taps on when hard hats will expire and new ones will need to be re-issued. We also provide respiratory and hearing protection on every job site.”

According to the U.S. Bureau of Labor Statistics, the construction industry had 195,600 workplace injuries and 3,600 workplace illnesses in 2019. More specifically, Pennsylvania’s non-fatal workplace injury and illness rates were above the national average. The Center for Construction Research and Training’s Fatality Map Dashboard also shows that since data started being collected in 2011, Delaware has had 17 fatal injuries in construction, New Jersey has had 145, and Pennsylvania has had 213 fatal injuries. With these statistics in mind the importance of practicing safety is pretty clear.

“Safety Weeks such as this one exist so we can create awareness and reduce the number of fatalities our industry sees,” concludes Tom. “Chances are that some of the fatalities seen could have been prevented if better communication and more training took place. That’s why our team at D&B is focused on achieving safety every day through daily safety checks on site.”

Let us know how you work to prevent incidents on the job site in the comments below, and consider joining D&B and thousands of other companies in taking the pledge to be Safe + Sound – both throughout this week and every day.

With the prospects of a slightly warmer than average summer looming, it is important that those within the industry, and anyone working long hours outside, brush up on their knowledge of high heat safety. At D&B, safety is our standard. Our Safety Committee meets monthly (and will actually be discussing this relevant topic at our upcoming meeting) to help ensure that all members of our team and trade partners are safe. In the name of safety and looking out for our brothers and sisters in the industry, we wanted to share these helpful tips from D&B’s Safety Director and Construction Manager, Tom Rinaldo:

1. Stay Hydrated

Tom suggests that all D&B employees and trade partners stay well hydrated during the summer by drinking one cup of water every 15 to 20 minutes. On every D&B jobsite, we provide ample amounts of water for our employees and trade partners. It is important to hydrate the night before and after you work on a jobsite. Doing so puts less strain on the body to replace the fluids you have lost while sweating.

If water is not easily accessible or you are looking for an alternative, Tom recommends trying drinks that have electrolytes, like Gatorade. Gatorade contains valuable electrolytes that can help maintain the ionic balance in your body. Gatorade and similar drinks are also able to replace electrolytes that you may have lost while sweating, and having enough electrolytes is vital to keep your body functioning properly while on the jobsite.

2. Avoid Salty Foods

Tom urges team members to avoid eating salty foods. Why? They dehydrate you. Foods such as pretzels, potato chips, and popcorn can be a great snack, but in the summer months you may want to trade them in for your favorite fruits and veggies.

It can be hard to avoid eating salty foods on the jobsite, especially since the convenience of fast food restaurants can be tempting when you’re on the go. Fast foods like McDonald’s can be unhealthy – and even unsafe during the summer months – for more reasons than just its high sodium content.

Let’s say you’re on your way to the jobsite and decide to stop at McDonalds to get a classic Big Mac Meal with fries and a soda. This meal is 1,320 calories; 51 grams of this is fat, 192 grams is carbs, and 1,425 mg is sodium.

Construction workers can burn up to 300 calories per hour while on the job. This is three times as many calories as the average office worker who only burns around 102 calories per hour. Because of this, it is recommended that individuals completing manual labor on the jobsite consume at least 2,500 calories a day. After eating your Big Mac Meal, you have already consumed 79% of your daily fat, 64% of your daily carbs, and 60% of your daily sodium, and you still need to consume 1,180 more calories to obtain the recommended 2,500 calories.

Not only are you consuming too much sodium, but regular consumption of fast food meals such as this can be unhealthy to you and may even influence other workers to follow suit. To stay healthy on the jobsite, we recommend packing protein and complex carbohydrates low on salt, with some healthy snacks (see the next tip for more info on this).

Start your day off right with this easy to make breakfast burrito. For lunch, try saying adios to the usual cold cuts and deli meats high in sodium and nitrates by trading them in for the ultimate trifecta: something delicious, healthy, and safe for your body in the heat. We think this Protein Packed Pasta Salad looks delicious! While you are feeling inspired, check out these 15 tasty and uncomplicated lunches that are packed with protein.

3. Eat Water-Filled Foods

Watermelons, strawberries, oranges, peaches, cucumbers and other fruit are great snacks, especially in the summer while on the jobsite. In addition to drinking water, eating water-filled fruits and other snacks is a great (and healthy) way to stay hydrated.

One great lunch option is a cucumber-watermelon salad with avocado and bell pepper. Aside from being tasty, it is simple, too! All you need to do is cube these foods and add the dressing of your choice.

Another very simple – yet effective – snack that will keep you hydrated is frozen grapes. Find more inspiration for delicious recipes that will help keep you hydrated here and here.

Let us know which recipes you’d like to try and what your go-to healthy lunch is on the jobsite in the comments below!

4. Wear Loose, Light Colored Clothes

Darker clothes attract more sunlight. Naturally, this rule applies on the jobsite in the summer. Our Safety Director, Tom, suggests this simple tip that can make quite the difference: wearing loose, light-colored clothes.

5. Get Some Shade

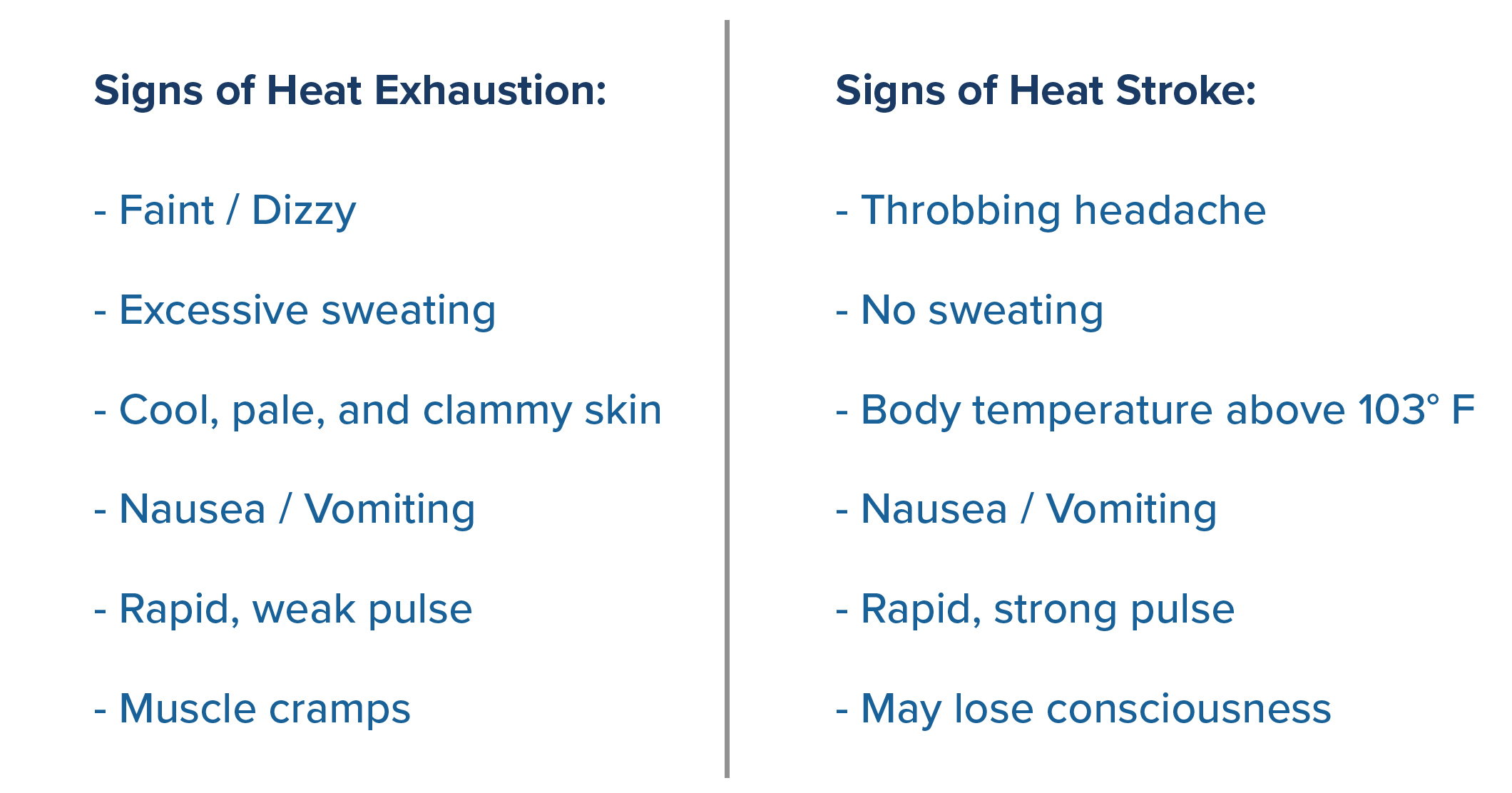

Potentially the most important tip out of the five, make sure to get some shade. Naturally, jobsites can get extremely hot in the summer months. Our Safety Director encourages all workers to take breaks in the shade to cool down and to be vigilant for signs of exhaustion, both for themselves and their co-workers on the jobsite. Having a buddy system may work well here. It is important to watch for the following signs of heat exhaustion and heat stroke for everyone on the job:

The Benefits of An Acclimatization Plan

Implementing an acclimatization plan is one way to prevent heat exhaustion. Simply put, this allows workers to get used to the high-heat conditions of the summer. This should take place over a one to two-week period. For new workers, the schedule should accommodate for no more than 20% exposure to heat on day one, with an increase of no more than 20% each day. If the worker has had experience on the job, you should do the same sort of process over a four-day period. Start day one at 50%, move to 60% on your second day, and 80% on your third day. By the fourth day you will be at 100% exposure. Tom supports this kind of plan if he feels the situation is right for it, although the tri-state area that D&B covers usually doesn’t require this since the seasons are well-balanced.

Trend 1: LEED and Green Building

“A ‘Green’ building is a building that, in its design, construction or operation, reduces or eliminates negative impacts, and can create positive impacts, on our climate and natural environment. Green buildings preserve precious natural resources and improve our quality of life” (WGBC). In response to the COVID-19 pandemic, Green or LEED construction is changing. The U.S. Green Building Council, creators of the LEED certification, plans to promote healthier and safer air quality indoors with adjusted certification criteria incentivizing the creation cleaner air systems. In 2021, there will be more building materials and components that help get LEED certification. One interesting and somewhat new development is a form of self-healing bio-concrete. This is a compound of concrete and bacteria that produces limestone when exposed to air and water, which helps with the impermeability of the surface. It costs around $240 per cubic meter. For reference, normal concrete usually costs between $200-$300, making it still cost efficient. Green building will continue to grow throughout the next decades and new technology and policy will come out to reinforce it as time goes by.

Trend 2: Modular Construction

The construction industry is rapidly moving towards modular materials because of its cost and time efficiency. Modular building is anywhere from 20% – 50% faster than traditional construction. It is also around 20% more cost efficient to build modular instead of traditional because of the reduced labor and time costs. Modular building also cuts the waste output almost in half due to optimal fabrication and pre-planned units. Everything is built off the construction site, which reduces the challenges of regular construction such as weather, limited working hours, and space. Overall, modular building is great for symmetrical and repeating buildings where sections can be made and stacked or attached to each other easily like in apartment or office buildings.

Trend 3: Safety

As it should be, safety is a huge trend in 2021. The old workplace safety system focused on recognizing problems and fixing them after someone gets hurt or a problem occurs. The new system getting pushed in the industry is based on prevention through education and training and recognizing issues before anyone gets hurt. This is why we have our Safety Committee meet monthly to discuss different topics of safety. Another large change in the safety category is better technology with Personal Protection Equipment (PPE). With more women entering the field, there is an increased awareness of the need for PPE to properly fit all employees to ensure safety. In addition, because of the COVID-19 pandemic there are policies across most companies including D&B that promote safe environments using masks, social distancing, and sanitization. When the pandemic hit, our team implemented a sign in and sign out sheet at every job site, making it easy for us to accurately perform contact tracing in the event that someone developed COVID-19 symptoms. D&B will continue to enforce this rule across all job sites moving forward. Learn more about our safety standards here.

Trend 4: Multi-Family

Multi-family construction is one of the fastest growing sectors of the commercial construction industry. Because of the lack of inventory in the housing market and changing demographics, multi-family construction is in high demand and will continue to grow in the following years. More people are looking for smaller, more affordable homes and condominiums with less maintenance than a normal single-family house. Research shows that 33% of people who are reaching age 55 are on their own. This is much different than what was the case 20 years ago. Currently D&B has multiple multi-family jobs under active construction and in the pre-construction phases. Throughout my internship, I shadowed the construction of The Reserve at Gring’s Mill, which you can view here.

Written by: D&B Intern, Alex Wolf

Alex culminated this list based on what he learned during his time at D&B. He is a Senior at Wilson High School who began shadowing various D&B employees in September of 2020. Alex will be attending Virginia Tech for Architecture in the Fall. “My internship experience at D&B made me realize that I want to pursue a career in residential remodeling and construction,” he explains. “I gained a lot of knowledge about the construction process and enjoyed being able to see entire construction projects from start to finish.”