Safe + Sound is a year-round campaign to encourage every workplace to have a safety and health program. It was launched by OSHA in an effort to gain safety awareness. Every year in August, OSHA has a Safe + Sound week, with this year’s taking place from Monday, August 9th to Sunday, August 15th.

This nationwide event recognizes the success of workplace health and safety programs and offers information and ideas on how to keep America’s workers safe. Seven businesses make up the list of organizers who participate in planning calls, working collaboratively with each other to develop and review Safe + Sound materials and communications, and leverage their own resources to support these efforts. In addition to OSHA, these businesses include large organizations, such as the National Safety Council and . The program also has 225 partners who are membership organizations that are responsible for communication and outreach throughout the year to promote Safe + Sound to their stakeholders.

D&B Construction is one of 68 companies throughout PA (and over 1,600 across the nation) who have signed up to participate in Safe + Sound Week 2021. We are excited to show our support and commitment to continue building safer jobsites. People come first at D&B. The safety of our employees, trade partners, and clients is always paramount in every project’s preparation and execution. In order to make this happen, safety and health are at the core of everything we do. Learn how here.

The Occupational Safety and Health Administration, better known as OSHA, was created in 1970 to ensure safe and healthy working conditions by setting and enforcing safety standards in addition to providing training, outreach, education, and assistance. You may have heard OSHA refer to the “Fatal Four” when describing the four most common causes of worker deaths on construction sites throughout the United States.

The four most common causes of worker deaths in this industry come from Falls,) which account for 33.5% of construction worker deaths), being struck by an object (11.1%), electrocutions (8.5%) and being caught in / between something accounted for 5.5% of construction worker deaths. According to OSHA, as of 2020 “one in five worker deaths in 2019 were in construction.” The “Fatal Four” were responsible for more than half (58.6%) of construction worker deaths. According to OSHA, if these “Fatal Four” causes could be eliminated, they would save 591 workers’ lives in America each year.

In 2020, OSHA gathered data on the top 10 instances of safety code violations. Learn what they are below, and hear from our Director of Construction and Safety Director, Tom, on how such issues can be avoided and prevented:

1. Inadequate Fall Prevention – 6,010 violations

What This Means: OSHA states that a violation could include not providing working conditions that are free of known dangers, failure to keep floors in work areas in a clean and dry state, as well as not providing required personal protective equipment at no cost to workers.

Tips on How to Prevent This: Our Safety Director, Tom, encourages the use of safety rails and body harnesses on every job site. “At D&B we provide these on every job site to give our workers the safest environmental possible.”

2. Inadequate Hazard Communication – 3,671 violations

What This Means: Simply put, this refers to the failure to inform all people on the job site of potential risks and hazards.

Tips on How to Prevent This: “At D&B we fill out a Job Safety Analysis (JSA) and Job Hazard Analysis (JHA) on all job sites,” explains Tom. “This helps us to ensure that we are communicating this vital information with all of our employees and trade partners. Communication is huge in enhancing safety.”

3. Unsafe Scaffolding – 2,813 violations

What This Means: Failure to abide to OSHA standards would include improper fall protection / fall arrest systems, unsuitable guardrail height, inadequate footing support, failure to complete inspections, etc.

Tips on How to Prevent This: Work with reputable scaffolding companies that you trust. “At D&B we complete daily and weekly inspections on the scaffolding on our site to ensure we are practicing proper scaffolding safety protocols,” says Tom.

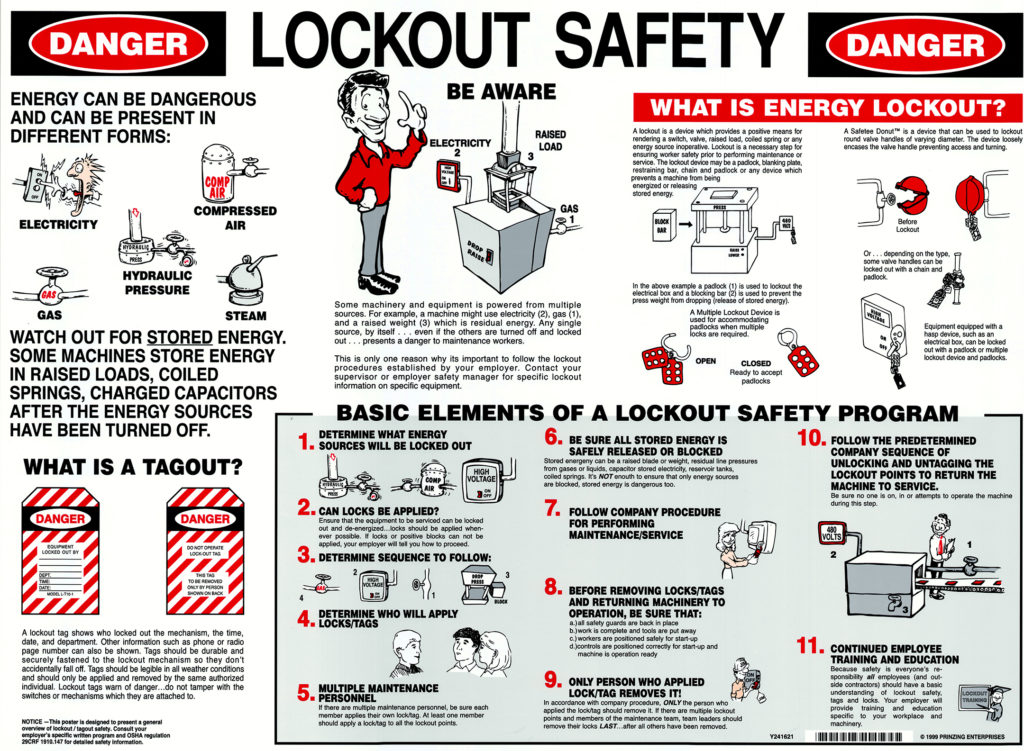

4. Failure to control hazardous energy (Lockout / Tagout Violations) – 2,606 violations

What This Means: Failure to address the practices and procedures needed to disable machinery or equipment that may expose workers to hazardous energy.

Tips on How to Prevent This: “There is no better way to ensure this mishap is avoided then by requiring all electricians on your job site to use lockout and tagout procedures on all powered equipment and panel boxes,” says Tom.

At D&B, we include the following lockout safety poster on our Safety Board at all jobsites:

5. Inadequate Respiratory Protection – 2,450 violations

What This Means: A violation would include not providing the proper respiratory protection.

Tips on How to Prevent This: “In addition to providing dust masks to all employees, it is important to utilize clean air machines and air scrubbers such as HEPA filters on your job sites,” says Tom. “In any situation where there are environmental hazards present, we as a company will hire a reputable remediation company to ensure the safety and health of all people on the job site. I highly recommend doing this when the elements require it.”

6. Unsafe Ladders – 2,345 violations

What This Means: This could include placing a ladder on a box or barrel, using ladders where there is unstable footing or soft ground, exceeding a ladder’s maximum load rating, ignoring nearby overhead power lines, moving or shifting the ladder while a person or equipment is on it, using an extension ladder horizontally as a platform, etc.

Tips on How to Prevent This: “Have your Site Superintendents check ladders on a daily and weekly basis. If any ladders are deemed unsafe or defective, they should be removed immediately,” says Tom. Unlike hard hats, for example, there is no specific expiration date for ladders. Following proper storage techniques and treating ladders with care can help in making them last longer.

7. Powered Industrial Truck Safety Violations – 2,093 violations

What This Means: This refers to improper vehicle use, lack of training, and a failure to re-certify operators every three years as required.

Tips on How to Prevent This: ” At D&B, we make sure all of our Pettibone and Lift operators are certified, and we require lift plans for any kind of crane lifts. This is something I recommend everyone get in the habit of making a standard practice.”

8. Inadequate Fall Prevention & Training Requirements – 1,773 violations

What This Means: Failure to provide proper fall prevention training is something that can easily be avoided if proper training and communication on fall prevention is completed on all job sites.

Tips on How to Prevent This: “All D&B Construction field personnel are OSHA certified, and we also hold training sessions throughout the course of the year,” explains Tom.

At D&B, we include the following fall protection poster on our Safety Board at all jobsites. This is an easy way to remind everyone on the job site of how to best prevent falls.

9. Unsafe Machinery and Inadequate Machine Guarding – 1,743 violations

What This Means: Failure to provide one or more methods of machine guarding to ensure the safety of the operator and others in the nearby area can result in an unsafe job site.

Tips on How to Prevent This: “All powered tools are inspected for proper and adequate guarding by a D&B employee, such as the Site Superintendent, before use,” says Tom.

10. Inadequate Personal Protective and Lifesaving Equipment, Eye and Face Protection – 1,411 violations

What This Means: Failure to make the appropriate personal protective equipment available to all employees at no cost is something that should not occur anywhere.

Tips on How to Prevent This: “Keep inventory of safety equipment, such as safety glasses and hi-visibility vests, for all of your employees. At D&B, we keep a document that is updated every time a new hire starts so we know the date in which they received all of their issued PPE. This makes it easy for us to keep taps on when hard hats will expire and new ones will need to be re-issued. We also provide respiratory and hearing protection on every job site.”

According to the U.S. Bureau of Labor Statistics, the construction industry had 195,600 workplace injuries and 3,600 workplace illnesses in 2019. More specifically, Pennsylvania’s non-fatal workplace injury and illness rates were above the national average. The Center for Construction Research and Training’s Fatality Map Dashboard also shows that since data started being collected in 2011, Delaware has had 17 fatal injuries in construction, New Jersey has had 145, and Pennsylvania has had 213 fatal injuries. With these statistics in mind the importance of practicing safety is pretty clear.

“Safety Weeks such as this one exist so we can create awareness and reduce the number of fatalities our industry sees,” concludes Tom. “Chances are that some of the fatalities seen could have been prevented if better communication and more training took place. That’s why our team at D&B is focused on achieving safety every day through daily safety checks on site.”

Let us know how you work to prevent incidents on the job site in the comments below, and consider joining D&B and thousands of other companies in taking the pledge to be Safe + Sound – both throughout this week and every day.

If you caught our social media post about Jessica’s suspiciously cute boots on our active jobsite at the future new headquarters for Riverfront Federal Credit Union, you are likely here to find out the official verdict from our Safety Committee Director, Tom.

The votes across our social platforms were pretty evenly split, but for those that know Jessica and know she would always put safety first, you win! For those still in denial that these shoes follow safety protocol, surprise! Jessica’s boots are both OSHA compliant and ASTM certified. (We know, we know… They looked way too cute to be). But we wouldn’t lie to you! They are I/75 C/75 steel-toe boots that are impact and compression resistant. They also have an oil and chemical resistant outsole that is completely slip resistant on dry and wet surfaces, too. Some of this brand’s products even have their electrical hazard certification for up to 18,000 volts!

If you are still in denial that these are steel toe boots, check out this video from our Safety Director, Tom, as he verifies that they meet safety standards. He also tells us what he originally thought when he first saw Jessica’s Xena boots on a job site.

So what are these nearly mythical boots called!? Not to worry – At D&B Construction Group, we’re all about efficiency and helping out our industry brothers and sisters. And that’s because we care. So of course, we will spill the beans about these handy full-grain leather boots. They are made by a company called Xena workwear for women. Best of all, they are made for women by women right here in the United States.

Xena workwear was founded as a result of the CEO’s own frustration from “working in a manufacturing environment where the only options were bulky, manly work boots.” Their CEO, Ana Kraft understands the importance of how what you wear can impact self-confidence and many other job-related factors that play a huge role in long-term career success.

So how did Jessica score these beauties?! It all happened about a year ago through a simple Google search. “I was searching for something better suited for me. I needed something more stylish that I could wear in the office,” she recalls. “I was also tired of the old, muddy, and uncomfortable boots I had been using for years.”

5 Stars for Xena

A year in, Jessica is more than happy with these shoes. “They are way more comfortable than the old shit kickers I had,” she says with a laugh. Jess has the Gravity Safety Shoe, which come in three other cute styles. They also make safety boots, like this pair that another one of our D&B team members, Angela, recently purchased for when she is on our active job sites.

Although new to the construction industry, Angela is already hooked and thankful Jessica made the recommendation. Meanwhile, Jessica has been with D&B Construction Group for nearly 4 years. She is an LEED AP certified Project Manager that has managed design and construction projects for some impressive buildings across the United States for well-known clients like Harley Davidson, Calvin Klein, The North Face, Birkenstock, and Michael Kors to name a few. Likewise, Jess has also completed many impactful projects locally for Tower Health, Penn National Gaming, Hottenstein Orthodontics, S&T Bank, Gold’s Gym and more.

Both ladies regularly have to leave the office to head out on the jobsite. “Not having to worry about changing shoes as I go back and forth between the office and job sites just makes my day to day easier,” says Jessica. As a vital part of D&B’s operations here at the office, Jessica’s Xena’s have been a game changer in her day to day by making it easy to transition from office to job site.

“These boots are so comfortable that I sometimes forget I’m wearing them once I get back from a job site,” she explained. And it is no wonder, since they feature comfortable ankle padding, a lightweight design, breathable lining with air-flow tech, and an impact absorbing insole. Plus, just look at how on point their packaging and branding is! Xena boots even come with a card verifying that they are OSHA compliant and ASTM certified. This may definitely come in handy for those that think your shoes are too stylish to also be safe on the job.

Be sure to pass this brand along to other women in construction and other STEM-related careers. Ladies: Check out Xena’s Facebook group Xena Moves. This group was created for women in STEM and the Trades who are looking for a safe haven to connect with like-minded professionals and to share fun work style ideas! This is how the Team D&B ladies wear their #xenasatwork:

PS: For those of you who may have guessed wrong about Jessica’s boots being OSHA compliant – Don’t fret! “I get questioned all the time,” she says. “People ask me if they are legit, and I just encourage them to step on my toes.”